On-line image analysis-based focusing method of laser direct writing system

A technology of laser direct writing and focusing method, which is applied to the photoplate making process, optics, and optomechanical equipment of the patterned surface, which can solve the problems of limiting the material range and damage of the laser direct writing system, and achieve the improvement of writing quality and yield , reduce damage, widen the effect of the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0029] A focusing method of a laser direct writing system based on online image analysis, the laser direct writing system includes an objective lens and a camera, and the focusing method includes the following steps:

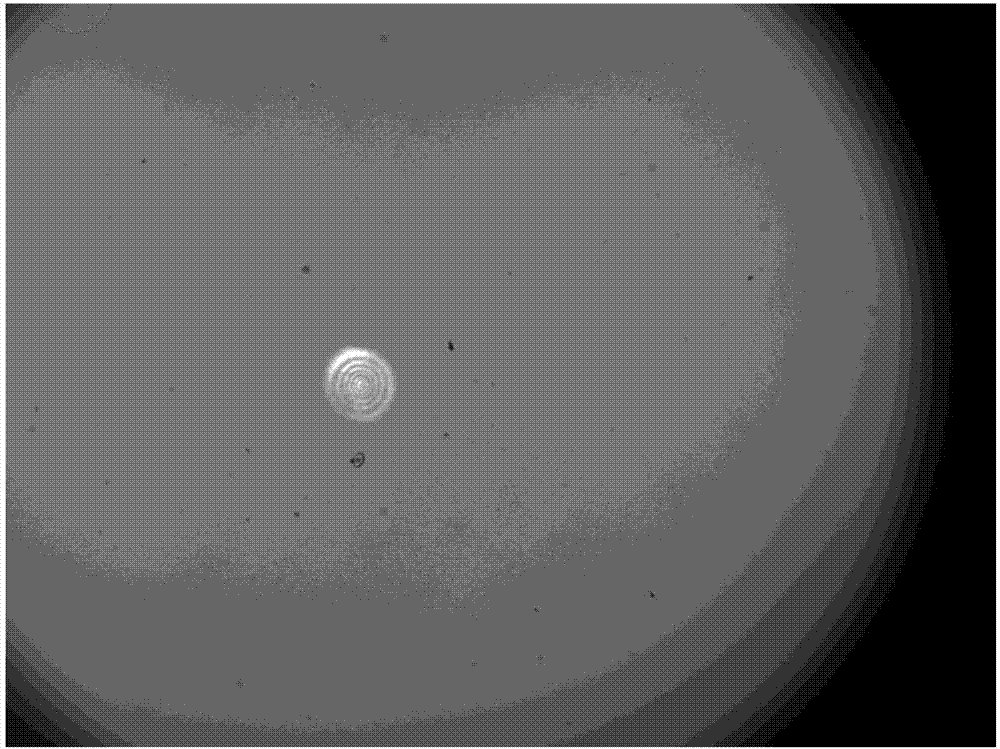

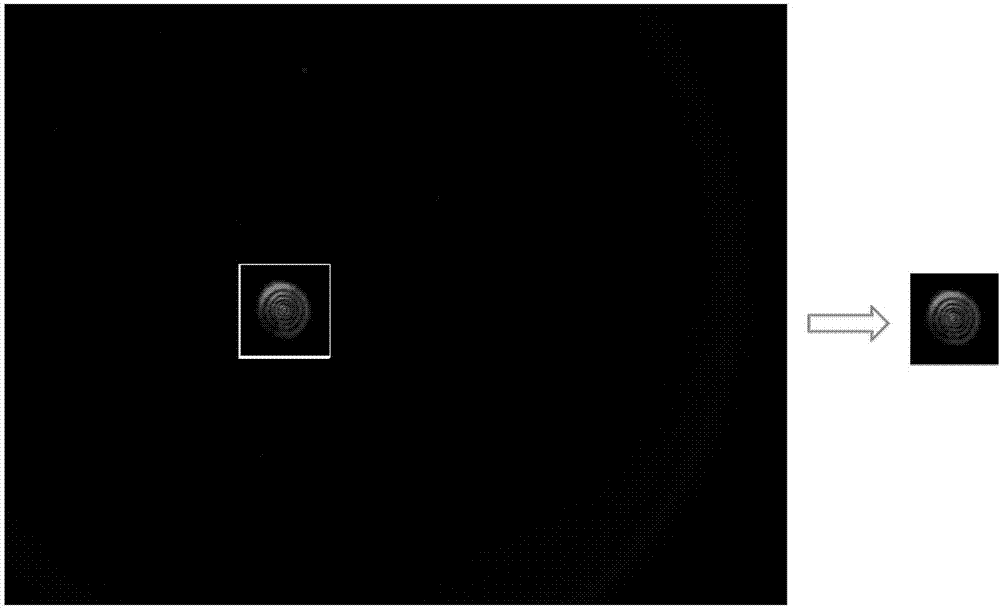

[0030] 1) Fix the Sn film sample with a thickness of 40nm on the glass substrate, and set the height of the objective lens to a certain value Z near the target height through rough focus adjustment i , where Z i is 52 μm; turn on the LED lighting source, turn off the focusing light source, and collect the image of the sample surface through the camera; the image at this time has only the background and no focus spot, which is called the background image; figure 1 shown. Coarse focusing uses precision threaded electric nuts, or piezoelectric ceramics, or linear motors to drive the sample or objective lens to move so that the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com