Nonlinear gasket-based flange bolt pre-tightening load design method

A design method and flange bolt technology, applied in computer-aided design, calculation, special data processing applications, etc., can solve the problems of reducing the rebound performance of gaskets, leakage of flange connection system tightness, increase of flange deflection angle, etc. problem, to achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

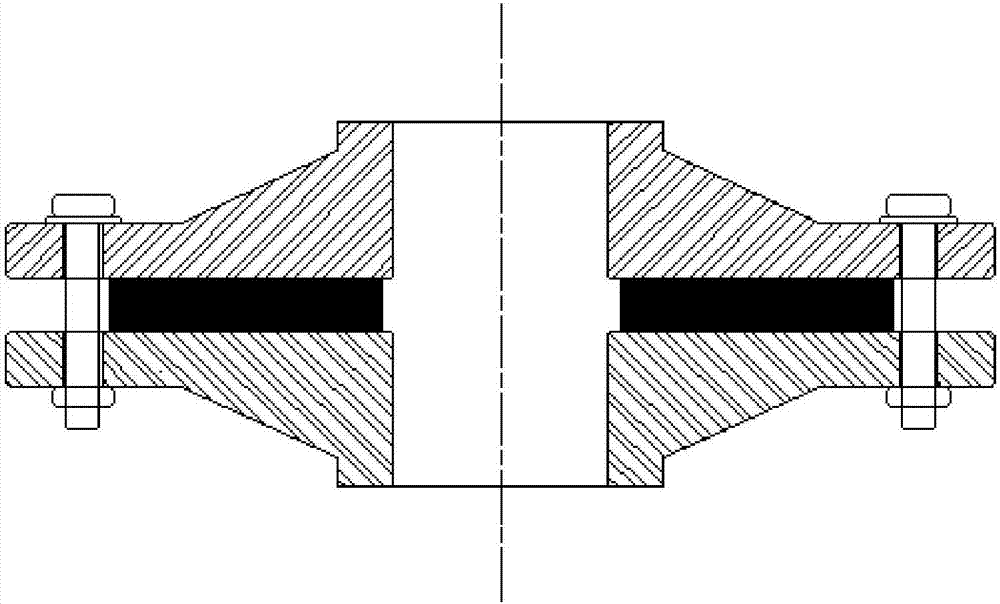

[0027] A method for designing the pretightening force of flange bolts based on nonlinear gaskets, comprising the following steps:

[0028] S1. Analyze the compression and rebound performance of the gasket.

[0029] Compression resilience is the basic mechanical property of gaskets. In the pre-tightening stage of the bolted flange connection, the good compression performance of the gasket is the basic condition to ensure the initial sealing between its surface and the flange surface, and the gasket is required to have better resilience during operation, so as to effectively compensate for the operation. The separation of the sealing surface caused by medium pressure, temperature and additional load of the flange under working conditions.

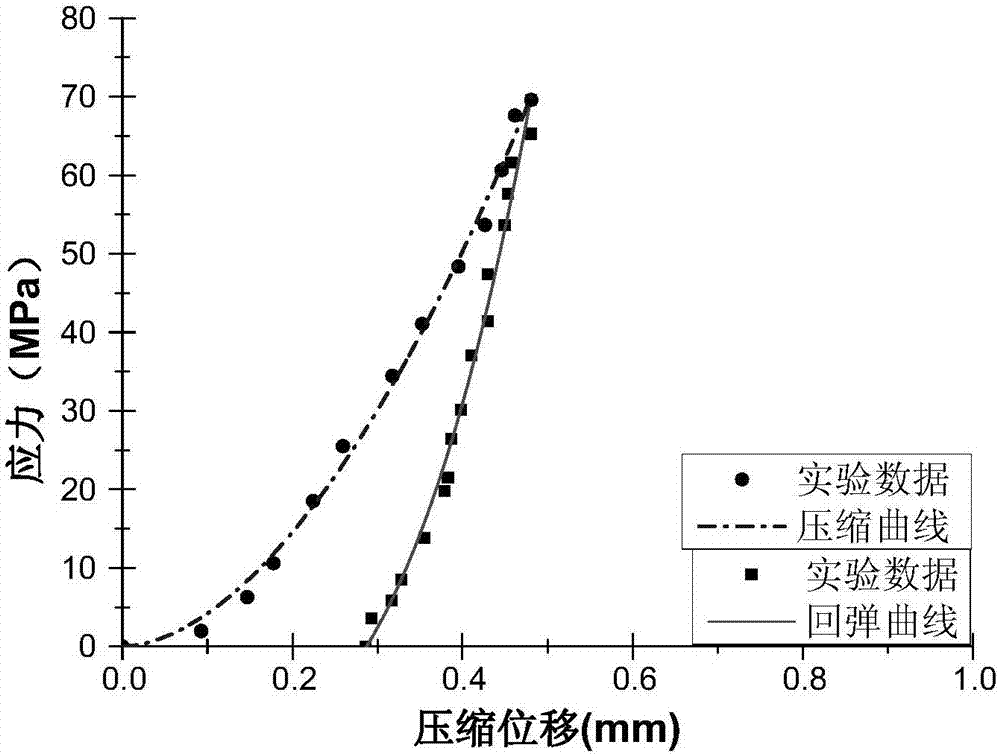

[0030] The compression springback curve of the flexible graphite composite gasket at the stress level of 70Mpa a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com