Integrated heat radiation structure of localization device

A heat dissipation structure and device technology, which is applied in the cooling/ventilation of substation/switchgear, modification of power electronics, structural parts of electrical equipment, etc., can solve the problem of inconspicuous heat dissipation, single heat dissipation method, poor heat dissipation, etc. Problems, to achieve the effect of obvious heat dissipation, increase the contact area, and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

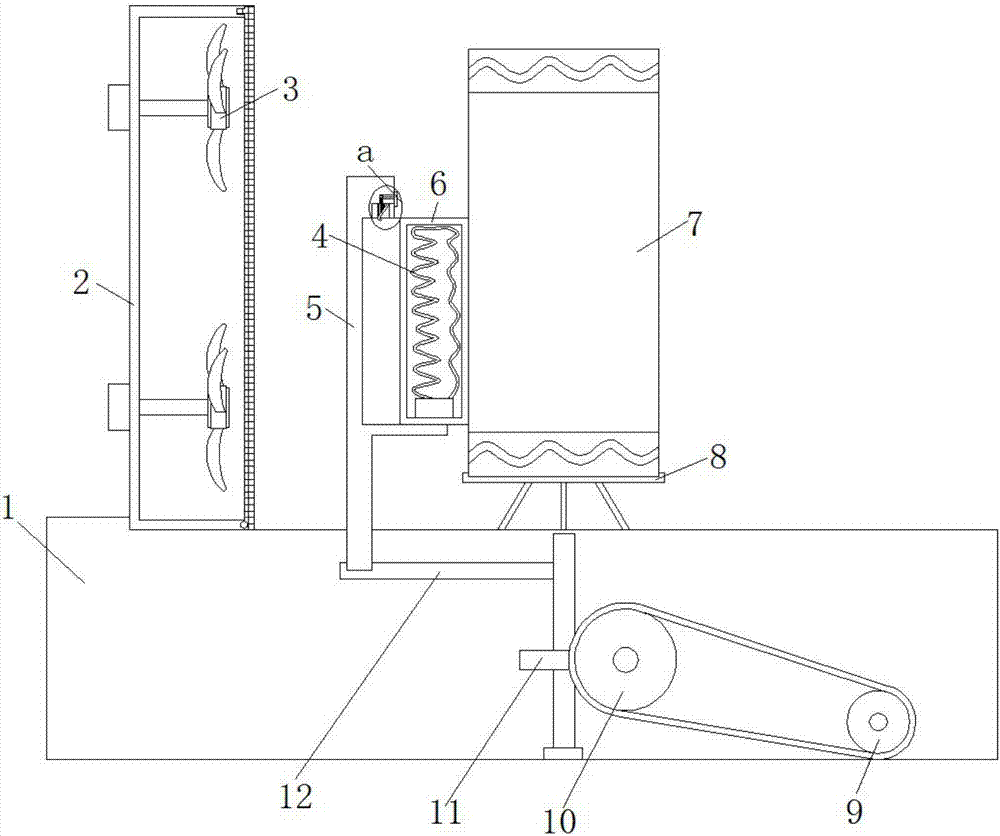

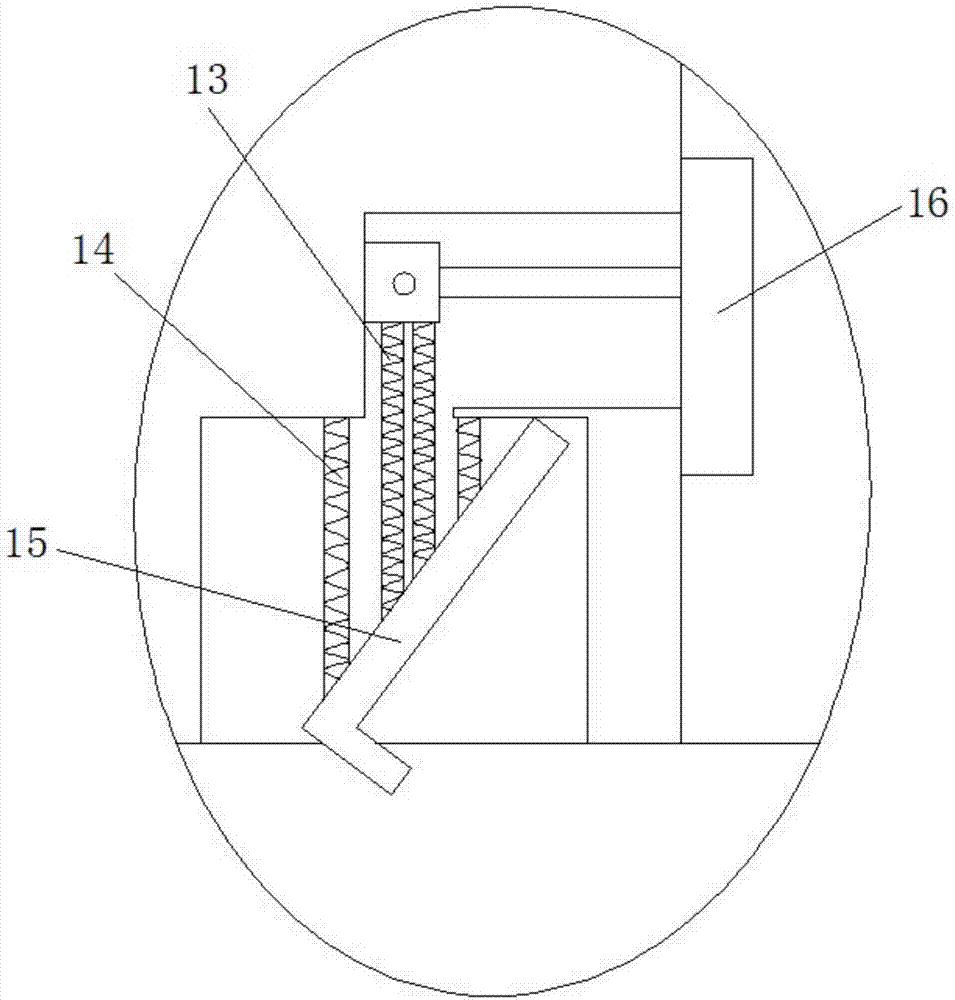

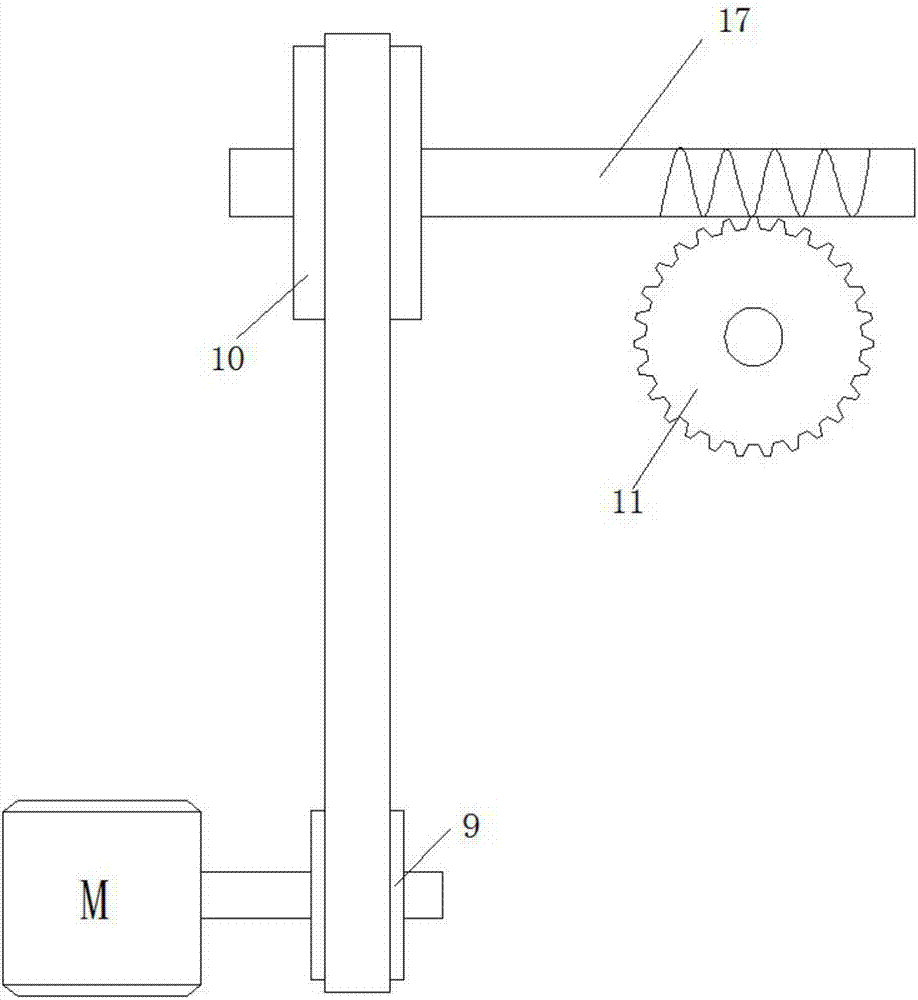

[0016] refer to Figure 1-3 , an integrated heat dissipation structure of an in-situ device, including a base 1, the lower surface of the base 1 is provided with anti-skid lines, the base 1 is coated with a polymer composite film, the base 1 is made of 304 stainless steel, and the base 1 is provided with There is a bellows 2 and a fixed frame 8, the bellows 2 is provided with a box door, and the box door is connected to the bellows 2 in rotation, the bellows 2 is provided with two cooling fans 3 through two first rotating shafts, and each first rotating shaft runs through The bellows 2 is also connected with the first driving motor arranged on the bellows 2, a body 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com