Automatic security bottle system and automatic controlling system thereof

A safety bottle, automatic technology, applied in the field of automatic safety bottle system and automatic control of the automatic safety bottle system, can solve the problems such as failure to give an alarm, achieve the effect of preventing fire, meeting differentiated needs, and improving personal and property safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

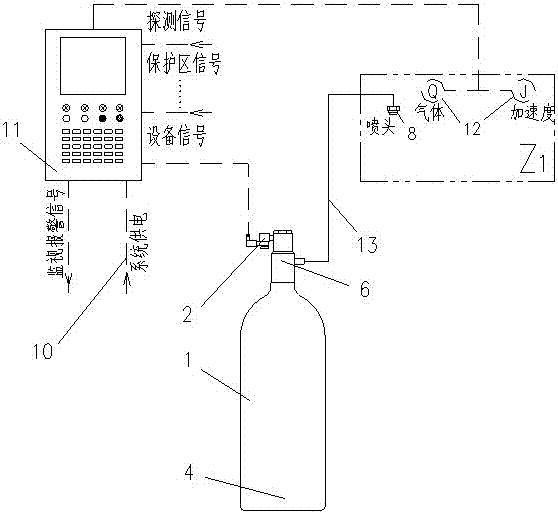

Embodiment 1

[0114] A plurality of signal acquisition elements 12 detect each protection zone Z1 to Zn, and transmit the acquisition signal to the controller 11; the controller 11 analyzes the acquisition signal;

[0115] When the protection zone Z1 catches fire, when the collected signal of the arranged smoke detector or temperature sensor exceeds the fire alarm setting value, the controller 11 sends out a danger alarm signal of the protection zone Z1, reminding personnel to check and confirm on the spot;

[0116] When the collected signals of the smoke detector and the temperature sensor in the protection zone Z1 both exceed the fire alarm setting value, the controller 11 sends an opening signal to open the bottle head solenoid valve 2 and the electric zone valve 7 in the protection zone Z1, and the protection zone Z1 The nozzle 8 of the sprayer automatically sprays the medium, so as to perform automatic fire extinguishing operation on the protection zone Z1.

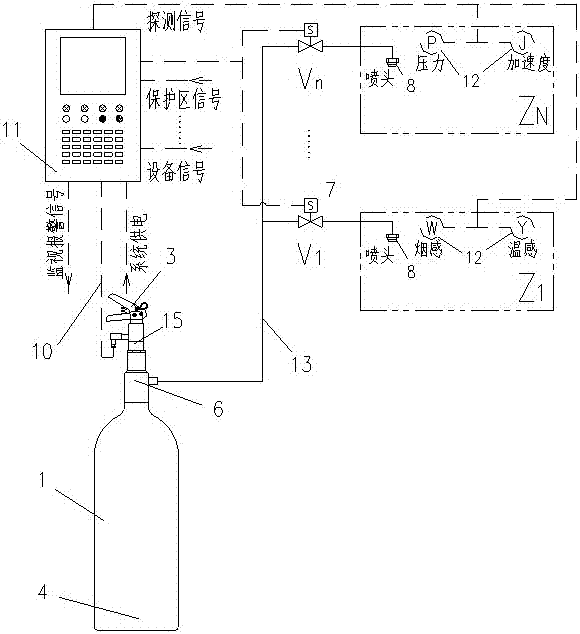

Embodiment 2

[0118] The signal feedback device of the BMS (battery management system) of the electric vehicle transmits the signal to the controller 11; the controller 11 analyzes the signal; when the BMS sends an abnormal signal, such as high temperature, excessive current, Wait, the controller 11 sends an open signal to open the bottle head electromagnetic valve 2 or the electromagnetic starter 15 and the electric area valve 7, and the nozzle 8 automatically sprays the medium, thereby cooling the battery box and protecting the flame-retardant safety; the abnormal signal is released , the controller 11 sends a shutdown signal, and the system returns to the original state, repeating this to ensure that the battery compartment and BMS are in a safe state or to suppress abnormal conditions.

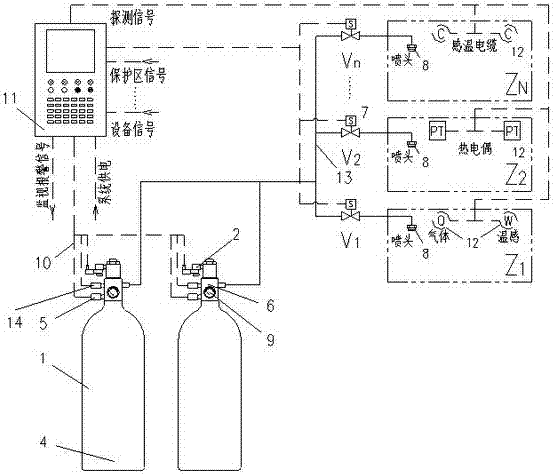

Embodiment 3

[0120] While the nozzle 8 in the protection zone Z1 is automatically spraying the medium, when the collected signal in the protection zone Z2 also exceeds the safety limit value, the controller 11 sends an opening signal to open the electric zone valve 7 in the protection zone Z2, and the nozzles in the protection zone Z2 8. Automatic spraying of medium, so as to protect the protection area Z2 safely.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com