Beam mold assembly positioning support for composite material multi-beam box section co-solidifying forming and assembly technique

A technology for positioning brackets and composite materials, which is applied in the field of beam mold assembly positioning brackets for composite multi-beam box section co-curing molding, can solve problems such as poor molding quality, shorten the manufacturing cycle, simplify the process operation, and ensure the thickness and axis. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

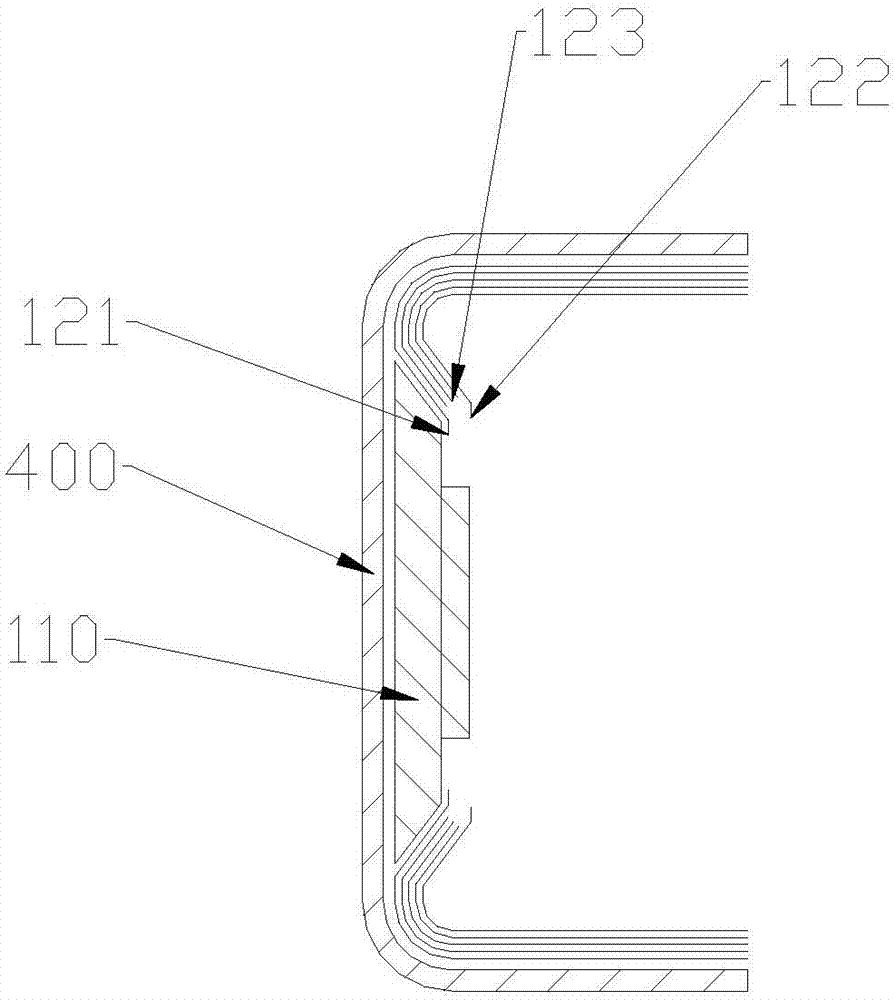

[0054] A beam mold component positioning bracket for co-curing molding of multi-beam box sections of composite materials, such as Figure 12 As shown, there are two sets of positioning brackets 300 arranged opposite to each other, and at least two sets of fixing plates 330 opposite to each other are respectively arranged on the positioning brackets 300 .

[0055] Such as Figure 12As shown, the positioning bracket 300 is provided with a positioning plate, and the positioning plate is provided with positioning pin holes. The positioning bracket 300 is composed of a crossbeam 310 and a vertical beam 320 fixed to each other, and the fixing plate 330 is arranged on the vertical beam 320 . The horizontal beam 310 and the vertical beam 320 are perpendicular to each other. There are at least two vertical beams 320 . The height of the positioning bracket 300 is smaller than the height of the beam mold assembly.

[0056] The process of using the above-mentioned composite material m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com