Mechanical-hydraulic compound energy recycling system based on flywheel and energy accumulator

A composite energy and recovery system technology, applied in transportation and packaging, auxiliary drive devices, control devices, etc., can solve the problems of reducing energy utilization rate and achieve the effect of improving utilization rate, high energy density and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

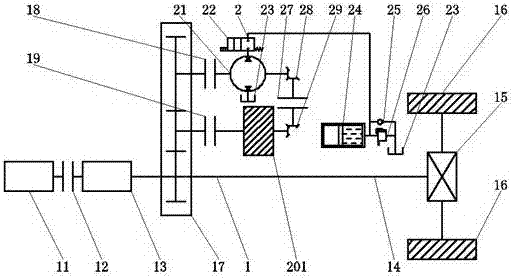

[0034] see figure 1 As shown, the present invention is made up of transmission device 1 and energy storage device 2, and energy storage device 2 is connected on the transmission device 1;

[0035] Transmission device 1 comprises engine 11, first clutch 12, speed reducer 13, transmission shaft 14, transaxle 15, wheel 16, gearbox 17, second clutch 18 and the 3rd clutch 19, engine 11, first clutch 12, deceleration The gears 13 are connected sequentially through shafts, the transmission shaft 14 is connected to the rear end of the reducer 13, the drive axle 15 is arranged at the rear end of the transmission shaft 14, the two ends of the drive axle 15 have wheels 16 respectively, and the gear box 17 is arranged at the front end of the transmission shaft 14. The second clutch 18 and the third clutch 19 are respectively connected on the gearbox 17;

[0036] The accumulator device 2 includes a hydraulic pump / motor 21, a switch valve 22, an oil tank 23, an accumulator 24, a one-way va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com