A temperature-sensitive asphalt heating and mixture precision mixing numerical control integrated device

A mixture and temperature-sensitive technology, which is applied in the field of temperature-sensitive asphalt heating and mixture precision mixing numerical control integrated device, can solve the problems of wasting energy resources, excessive pouring of asphalt, and aging of bottom matrix asphalt. Achieve the effect of reducing energy consumption, reducing performance impact, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

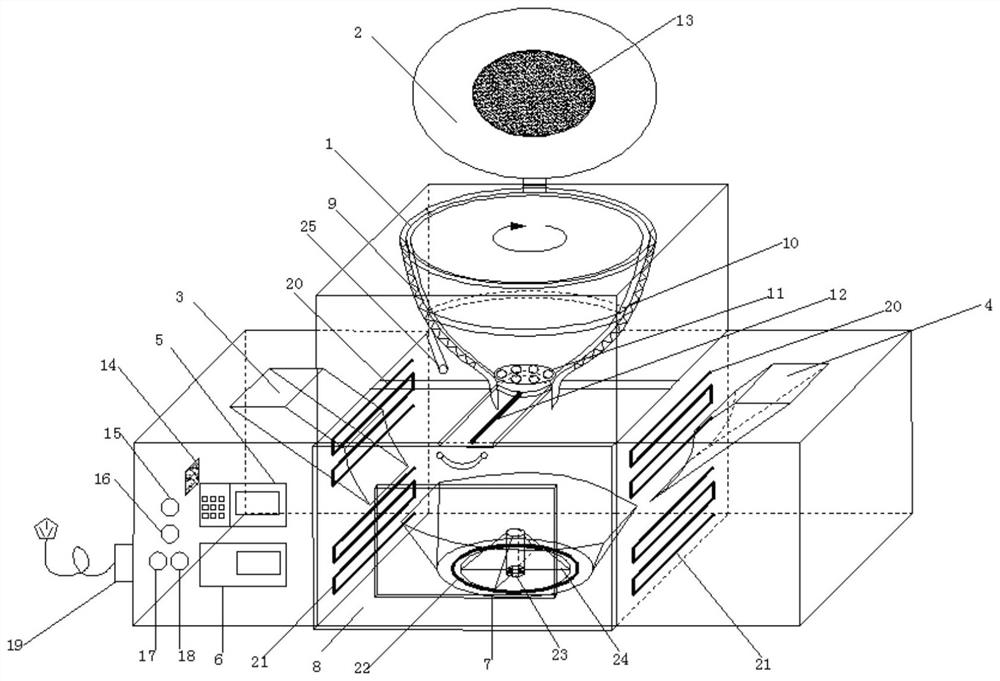

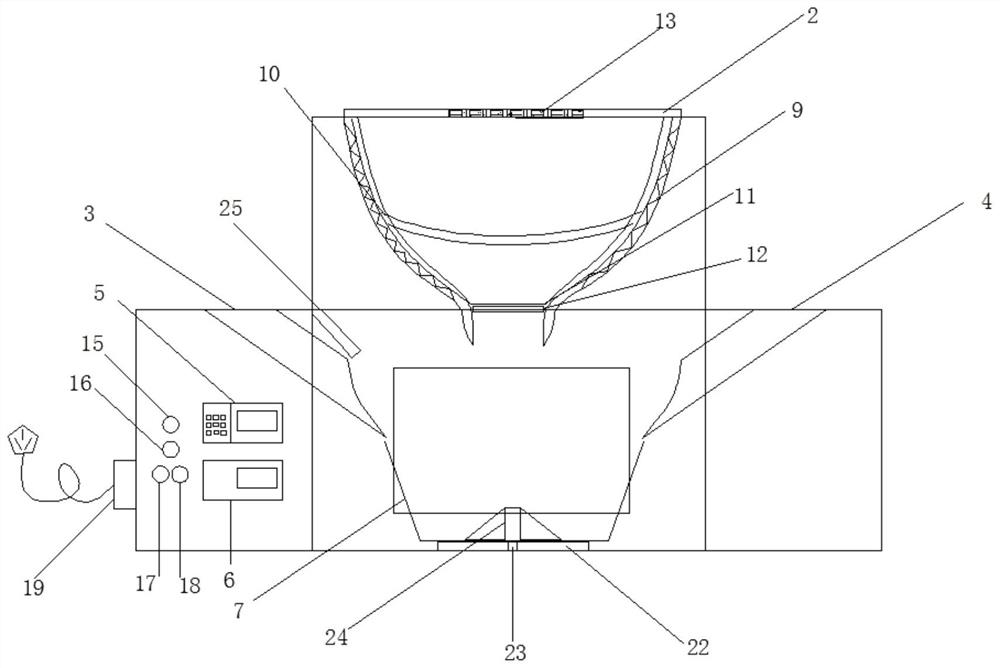

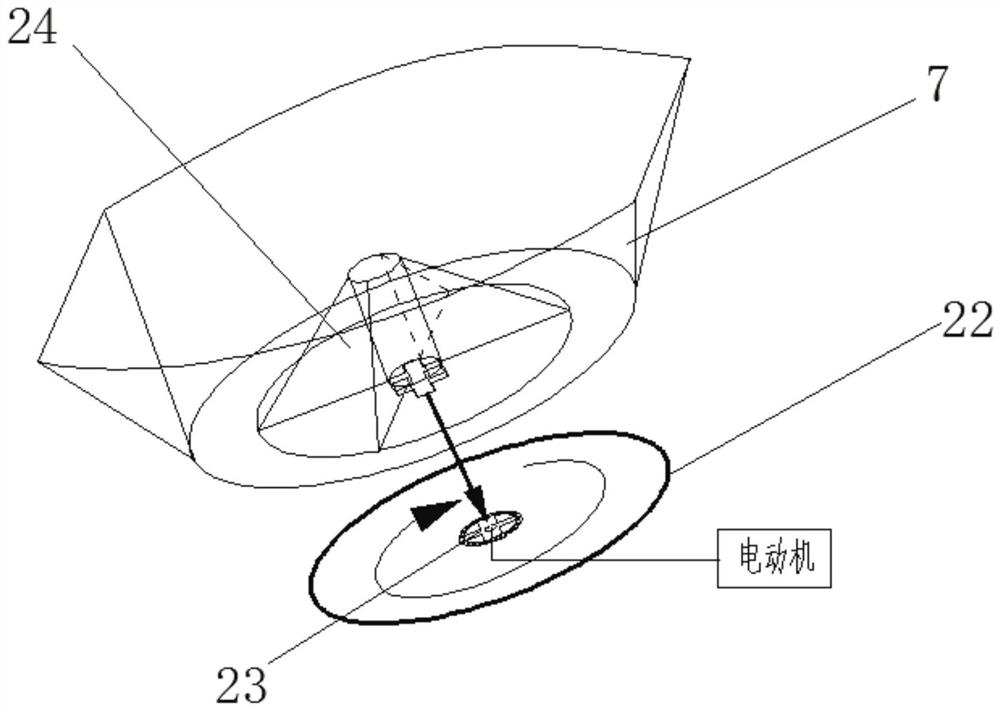

[0026] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0027] refer to figure 1 , figure 2 and image 3 , the temperature-sensitive asphalt heating and mixture precision mixing numerical control integrated device according to the present invention includes a heating pot 1, a mixing bin, a weighing device 22, a stirring pot 7, and a turntable bearing 10 for driving the heating pot 1 to rotate. And a power supply 19 for providing electrical energy; the heating pot 1 is located at the top of the mixing chamber, the top opening of the heating pot 1 is provided with a top cover 2, the bottom of the heating pot 1 is provided with a temperature-sensitive memory pot bottom plate 11, and the heating pot 1 The side is provided with the first heater 9, the weighing device 22 is located in the mixing chamber, the stirring pot 7 is located on the weighing device 22, and the top opening of the stirring pot 7 is located directly belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com