Vehicle body, rock breaking machine and method of breaking rock

A rock-breaking machine and car body technology, which is applied in the directions of earth-moving drilling, slitting machinery, vehicle parts, etc. The effect of good energy efficiency ratio and pertinence, improving construction efficiency, and stability of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

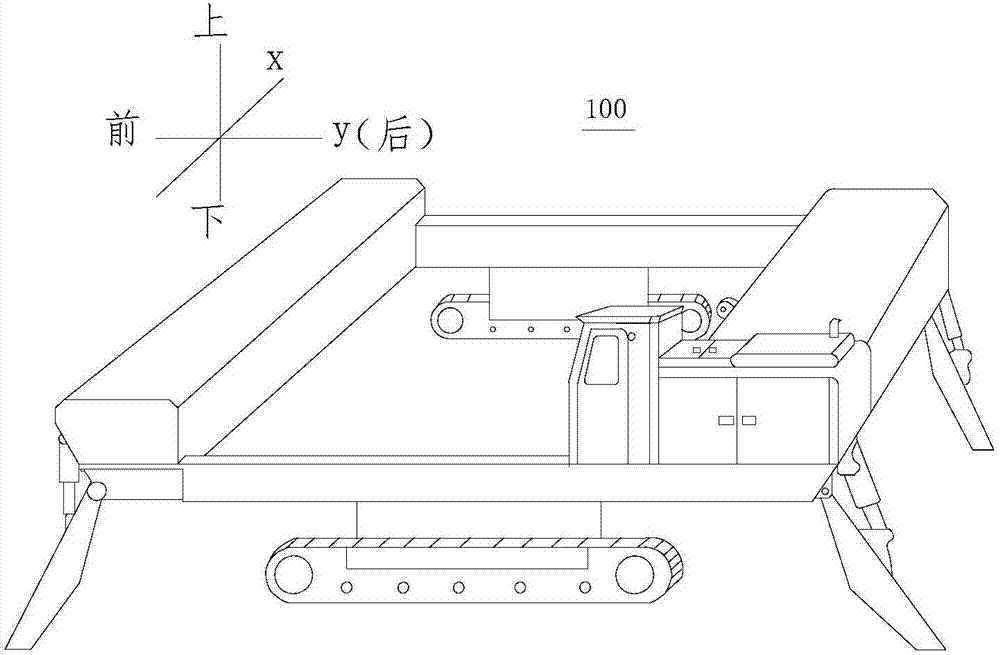

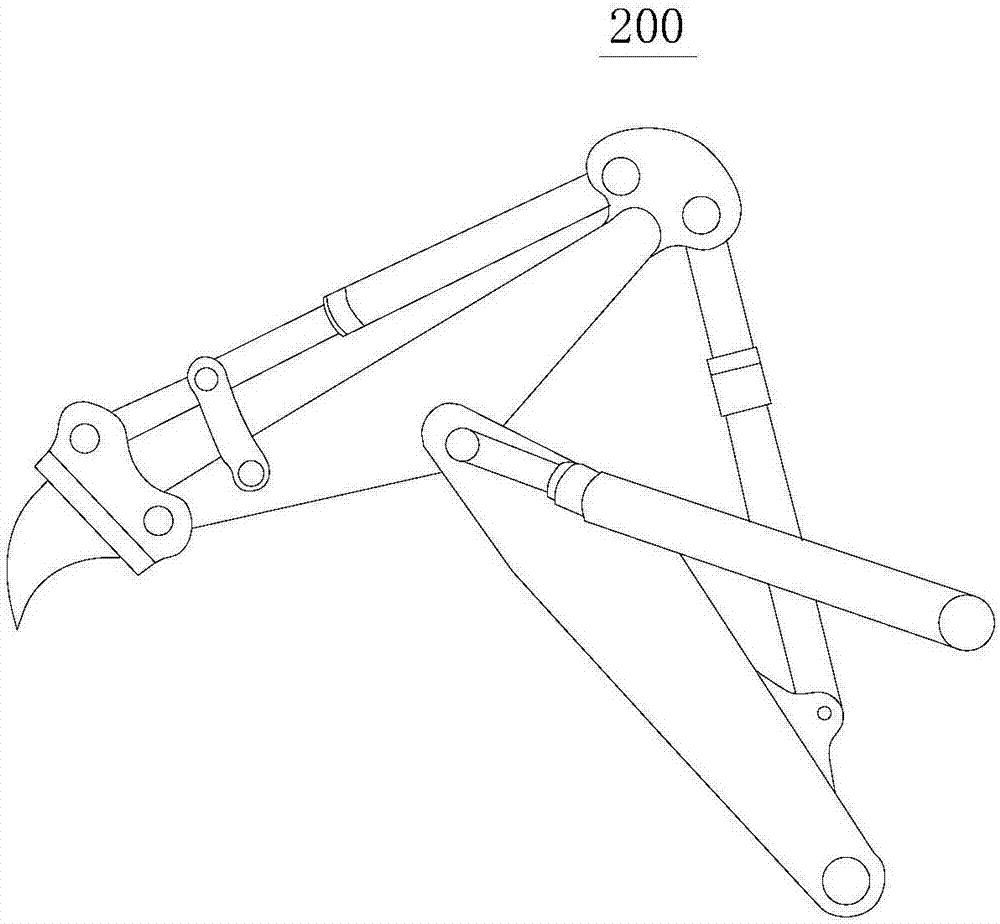

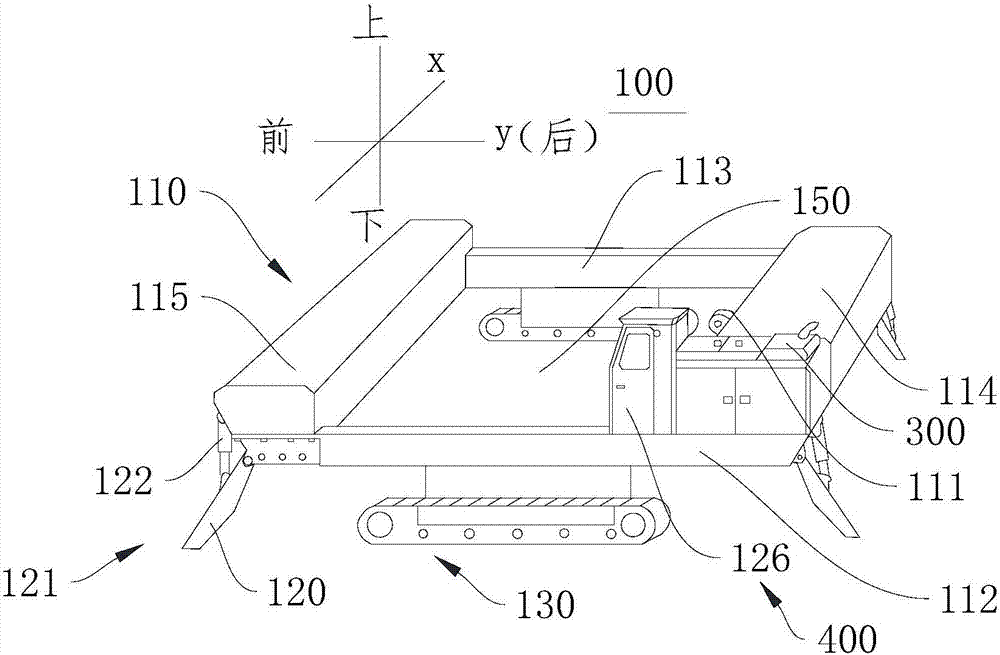

[0034] see figure 1 , figure 2 and Figure 4 , the embodiment of the present invention provides a rock breaker 1 , which includes a car body 100 and a rock arm 200 connected to the car body 100 . Wherein, the car body 100 includes a power part 300 , a hydraulic part (not shown in the figure), a control part 400 and a traveling mechanism 130 .

[0035] see image 3 , the power part 300 is used to provide power for the rock breaker 1, the hydraulic part (not shown in the figure) is used to transmit the power provided by the power part 300 to the working parts on the rock breaker 1, and the control part 400 is used to control the rock breaker. The work of Rock Machine 1.

[0036] see image 3 , the vehicle body 100 is provided with a hollow portion 150 penetrating the vehicle body 100 from top to bottom. The vehicle body 100 includes a vehicle frame 110 and a traveling mechanism 130 , the vehicle frame 110 is connected with the traveling mechanism 130 , and the vehicle fra...

Embodiment 2

[0075] see Figure 7, The embodiment of the present invention provides a rock breaker 1, compared with the rock breaker 1 provided in the first embodiment of the present invention, the difference lies in that the structure of the connection assembly 111 provided in the second embodiment of the present invention is different.

[0076] In the second embodiment of the present invention, the connection assembly 111 includes a sliding seat 1116 and a horizontally arranged sliding rail 1118 .

[0077] The slide rail 1118 is fixedly connected with the vehicle frame 110 , and the slide seat 1116 is slidably connected with the slide rail 1118 . The direction in which the sliding seat 1116 slides relative to the sliding rail 1118 is parallel or nearly parallel to the length direction of the first balance member 114 .

[0078] The connection assembly 111 also includes a main function vehicle frame 1111 arranged at the end of the first balancer 114, and the sliding seat 1116 is connected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com