Waste heat collecting device for superhigh temperature shaft kiln feeding end

A technology of waste heat collection and feed end, which is applied in the direction of furnace control device, waste heat treatment, lighting and heating equipment, etc. It can solve the problems of easy blockage of waste heat collection device, low heat collection efficiency, easy to be oxidized and corroded, etc., to alleviate heat loss , Relieve dust blockage, solve the effect of easy erosion and aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

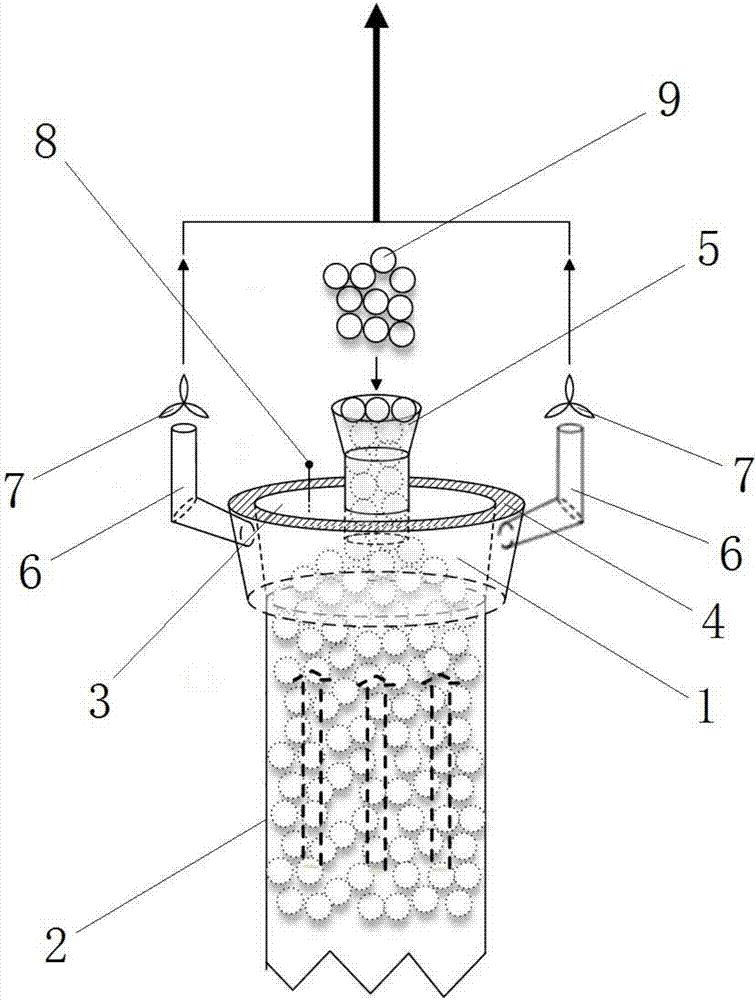

[0030] A waste heat collection device for the feed end of an ultra-high temperature shaft kiln, comprising a shell 1, a shaft kiln feed pipe 2, an end cover 3, a heat insulation layer 4, a feed hopper 5, an air induction pipe 6, a fan 7, a temperature Sensor 8, wherein the upper and lower ends of the housing 1 have a port respectively, the lower port of the housing 1 is connected with the nozzle of the shaft kiln feed pipe 2, the upper port of the housing 1 is connected with an end cover 3, and the outer circumference of the housing 1 Covered with a heat insulating layer 4, the air-introducing pipe 6 is fixedly connected to the housing 1, one end of the air-introducing pipe 6 extends into the interior of the housing 1, and the other is located outside the housing 1, and the air-introducing pipe 6 is located in the shell The port outside the body 1 is connected with a fan 7, the feed hopper 5 and the temperature sensor 8 are respectively connected to the end cover 3, the wide mo...

Embodiment 2

[0040] A waste heat collection device for the feed end of an ultra-high temperature shaft kiln, comprising a shell 1, a shaft kiln feed pipe 2, an end cover 3, a heat insulation layer 4, a feed hopper 5, an air induction pipe 6, a fan 7, a temperature Sensor 8, wherein the upper and lower ends of the housing 1 have a port respectively, the lower port of the housing 1 is connected with the nozzle of the shaft kiln feed pipe 2, the upper port of the housing 1 is connected with an end cover 3, and the outer circumference of the housing 1 Covered with a heat insulating layer 4, the air-introducing pipe 6 is fixedly connected to the housing 1, one end of the air-introducing pipe 6 extends into the interior of the housing 1, and the other is located outside the housing 1, and the air-introducing pipe 6 is located in the shell The port outside the body 1 is connected with a fan 7, the feed hopper 5 and the temperature sensor 8 are respectively connected to the end cover 3, the wide mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com