A solar cell photoanode containing graphene-based double-scattering structure

A technology of solar cell and photoanode, applied in the field of photoanode of solar cell, can solve the problem of low utilization rate of light, and achieve the effect of large specific surface area, good scattering effect and enhanced light capture efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

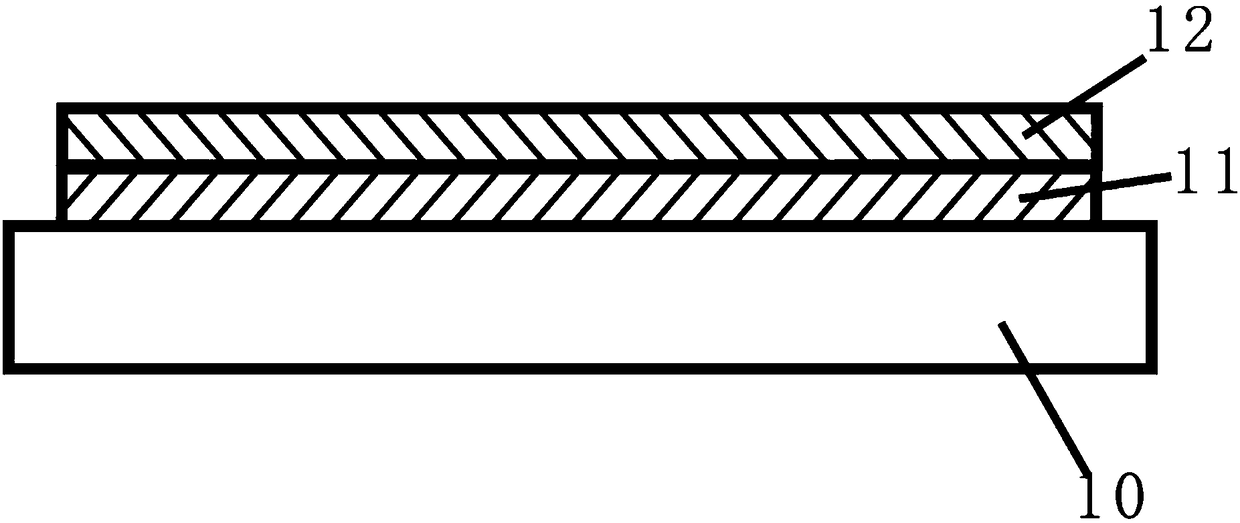

preparation example Construction

[0024] The preparation process of the double scattering structure photoelectrode is as follows:

[0025] Step 1, cleaning the transparent conductive substrate;

[0026] Step 2, preparing the first scattering layer on the transparent conductive substrate;

[0027] Step 3, preparing a second scattering layer on the first scattering layer;

[0028] specific,

[0029] Step 1, cleaning the transparent conductive substrate

[0030] For the transparent conductive substrate, select the FTO substrate, cut it, and then put it into acetone, ethanol, and deionized water to clean it ultrasonically for 30 minutes;

[0031] Step 2, preparing the first scattering layer

[0032] a) Preparation of TiO 2 hollow ball:

[0033] 2.6g of Ti(SO 4 ) 2 Add to 150ml of distilled water, stir for 30min; add 0.41g of ammonium fluoride and 1.2g of urea to the above solution, and stir for 50min; transfer the above solution to two 100ml hydrothermal kettles, and react hydrothermally at 180°C After 12...

Embodiment 1

[0039] Step 1, cleaning the transparent conductive substrate

[0040] For the transparent conductive substrate, select the FTO substrate, cut it, and then put it into acetone, ethanol, and deionized water to clean it ultrasonically for 30 minutes;

[0041] Step 2, preparing the first scattering layer

[0042] a) Preparation of TiO 2 hollow ball:

[0043] 2.6g of Ti(SO 4 ) 2 Add to 150ml of distilled water, stir for 30min; add 0.41g of ammonium fluoride and 1.2g of urea to the above solution, and stir for 50min; transfer the above solution to two 100ml hydrothermal kettles, and react hydrothermally at 180°C After 12 hours, after the reaction, the white precipitate in the hydrothermal kettle was collected and washed with water and alcohol for 3 times, and then dried in a vacuum oven at 80°C for 8 hours to obtain TiO 2 Hollow spherical powder;

[0044] b) Dissolve the single-layer graphene in acetone, sonicate until completely dissolved, the concentration of the single-laye...

Embodiment 2

[0050] Step 1, cleaning the transparent conductive substrate

[0051] For the transparent conductive substrate, select the FTO substrate, cut it, and then put it into acetone, ethanol, and deionized water to clean it ultrasonically for 30 minutes;

[0052] Step 2, preparing the first scattering layer

[0053] a) Preparation of TiO 2 hollow ball:

[0054] 2.6g of Ti(SO 4 ) 2 Add to 150ml of distilled water, stir for 30min; add 0.41g of ammonium fluoride and 1.2g of urea to the above solution, and stir for 50min; transfer the above solution to two 100ml hydrothermal kettles, and react hydrothermally at 180°C After 12 hours, after the reaction, the white precipitate in the hydrothermal kettle was collected and washed with water and alcohol for 3 times, and then dried in a vacuum oven at 80°C for 8 hours to obtain TiO 2 Hollow spherical powder;

[0055] b) Dissolve the single-layer graphene in acetone, sonicate until completely dissolved, the concentration of the single-laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com