Composite light anode for dye-sensitized solar cell and preparation method thereof

A technology of solar cells and dye sensitization, which is applied in the field of new energy development and utilization, can solve the problems of increased recombination rate, small electron diffusion coefficient, and restriction of photoelectric conversion efficiency of dye-sensitized solar cells, so as to increase adsorption capacity and reduce Recombination process, the effect of improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

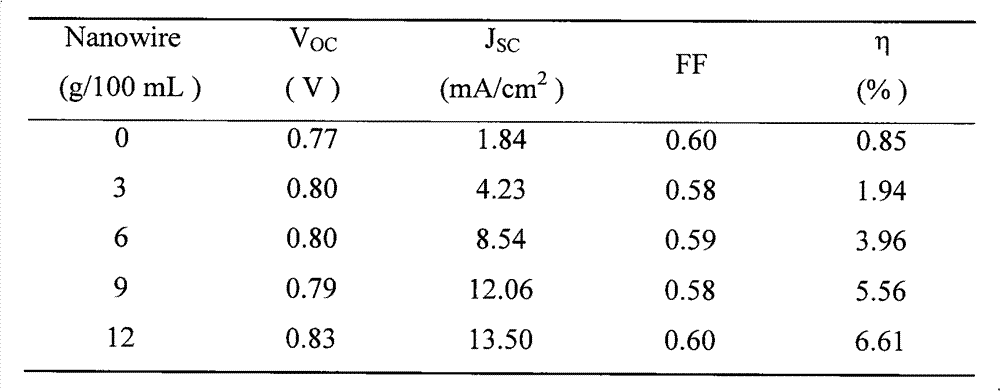

Examples

Embodiment Construction

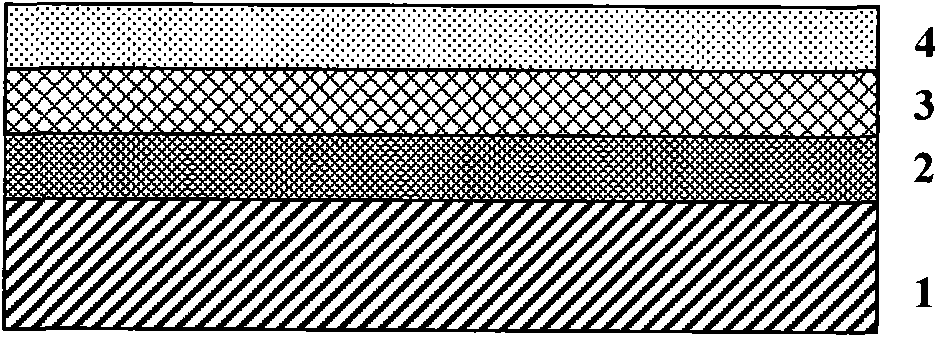

[0022] 1. Using magnetron sputtering technology to prepare a layer of dense TiO on the FTO transparent conductive glass film 2 film

[0023] Back vacuum 5×10 -4 Pa, sputtering pressure 2.5Pa, Ar and O 2 The flow ratio is 5:1, the sputtering power is 80W, the sputtering time is 8min, the substrate temperature is room temperature, TiO 2 The thickness of the dense film is 10-15nm.

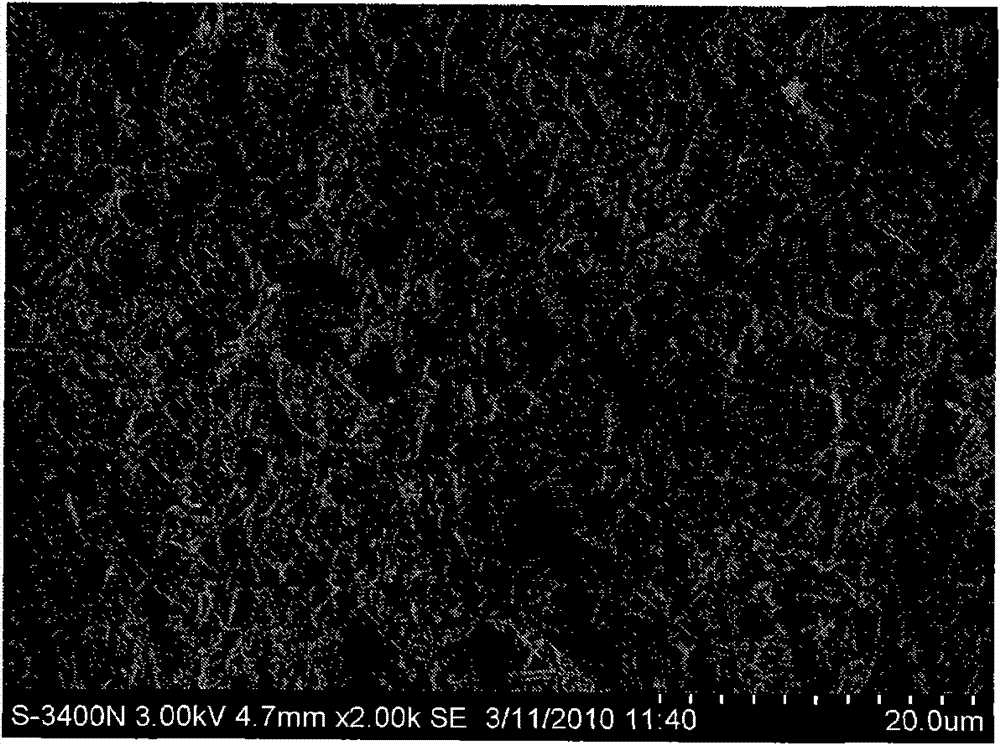

[0024] 2. Preparation of TiO by Hydrothermal Synthesis Technology 2 Nanowires

[0025] 1g TiO 2 After mixing the nanopowder with 30mL NaOH aqueous solution with a concentration of 10mol / L, and electromagnetically stirring for 15min, a white suspension was obtained, which was transferred to a 100mL high-pressure reactor, and then the reactor was placed in a thermostat at 180°C for 24h. . After the reaction, cool down to room temperature naturally, wash the white precipitate repeatedly with deionized water, then pickle with 0.5mol / L HCl until the pH value is equal to 7, then ultrasonically disper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com