A1-doped ZNO transparent conductive micro/nano wire array film and preparation method thereof

A nanowire array, transparent and conductive technology, applied in semiconductor/solid-state device manufacturing, nanotechnology, circuits, etc., can solve the problems of low deposition rate, non-existence, and good crystallinity of TCO thin films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

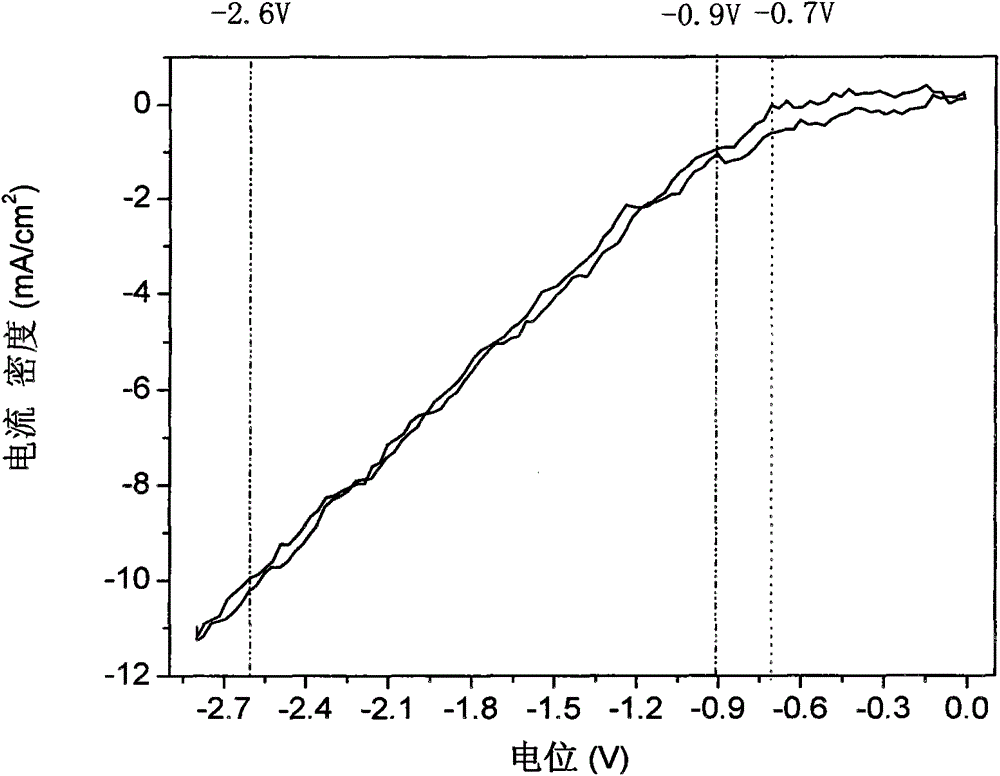

[0053] A growth process condition and steps of an undoped ZnO thin film of the present invention:

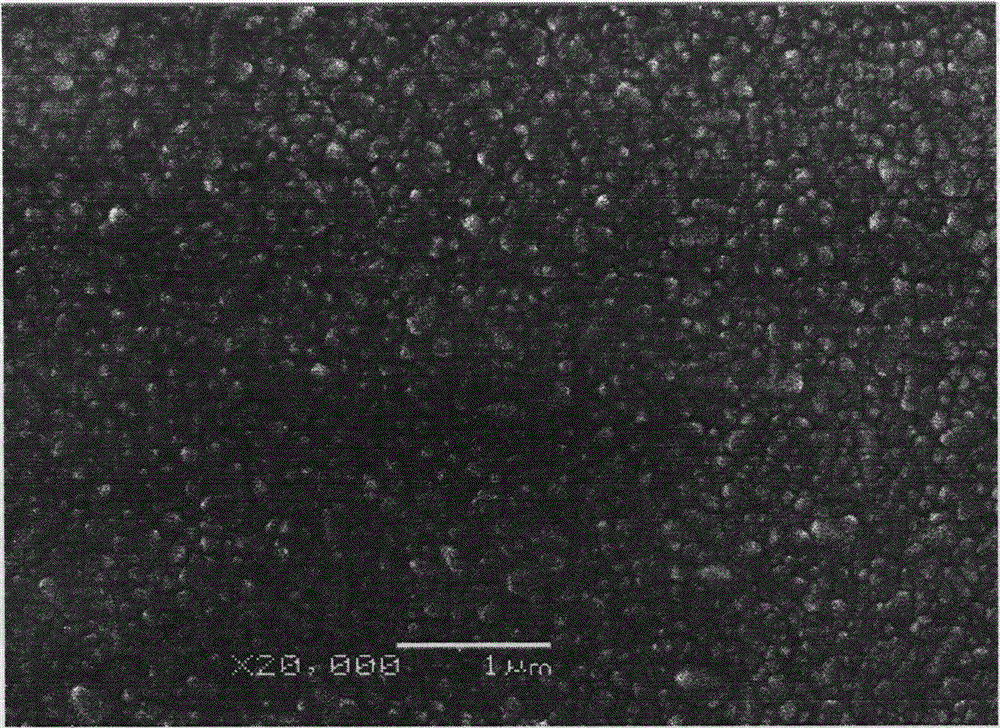

[0054] (1) Substrate: Fluorine-doped tin oxide (SnO 2 : F, FTO) glass, the sheet resistance is 18Ω / □, the surface morphology is as figure 2 shown;

[0055] (2) Solution system: Zn(NO 3 ) 2 Aqueous solution, concentration 0.025M;

[0056] (3) Electrodeposition process conditions: the distance between the plates is 3cm, the cathode potential is -2.5V, the electrodeposition temperature is 80±3°C, and the electrodeposition time is 20min;

[0057] (4) Crystallization heat treatment conditions: 530°C, heat preservation for 1h, air atmosphere, cooling with the furnace;

[0058] (5) Heat treatment under vacuum conditions: 450°C, heat preservation for 0.5h, vacuum, cooling down with the furnace.

[0059] The morphology of the prepared ZnO nanorod array film sample is as follows: image 3 As shown, the sheet resistance is 20kΩ / □, and the visible light transmittance is less than 60...

Embodiment 2

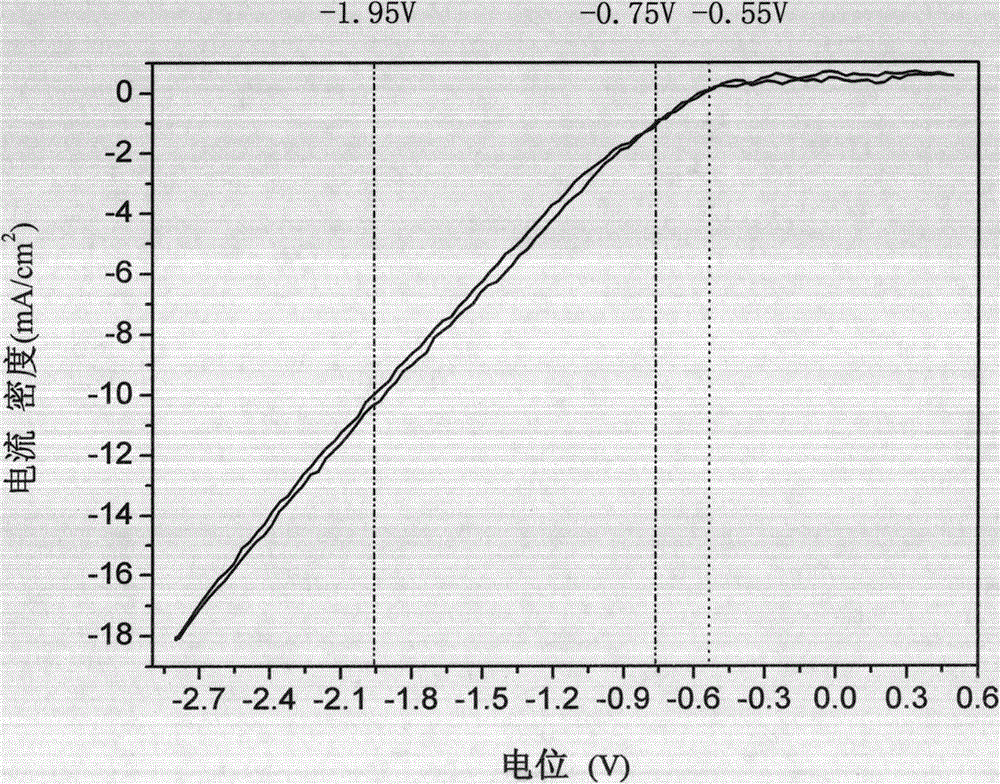

[0061] A growth process condition and steps of a transparent conductive Al-doped ZnO nanowire array film of the present invention:

[0062] (1) FTO glass substrate (with example 1);

[0063] (2) Solution system: Zn(NO 3 ) 2 with Al(NO 3 ) 3 Mixed aqueous solution, concentration 0.003M, Al / Zn atomic ratio = 3.3%;

[0064] (3) Electrodeposition process conditions: the distance between the plates is 2cm, the cathode potential is -1.5V, the electrodeposition temperature is 80±3°C, and the electrodeposition time is 1h;

[0065] (4) Crystallization heat treatment conditions: 530°C, heat preservation for 1h, air atmosphere, cooling with the furnace;

[0066] (5) Heat treatment under vacuum conditions: 450°C, heat preservation for 0.5h, vacuum, cooling down with the furnace.

[0067] The prepared ZnO: Al nanowire array film sample morphology is as follows Figure 4 As shown, the sheet resistance is 180Ω / □ (compared with the undoped ZnO thin film, the sheet resistance is reduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com