Drop-out fuse lower lead making table

A technology for lowering the lead wire of a fuse and making a table, which is applied in the direction of fuse manufacturing, etc., can solve the problems of messy job sites, low requirements for operator proficiency, and high degree of automation, and achieve compact and tidy job sites, low requirements for proficiency, and automation. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

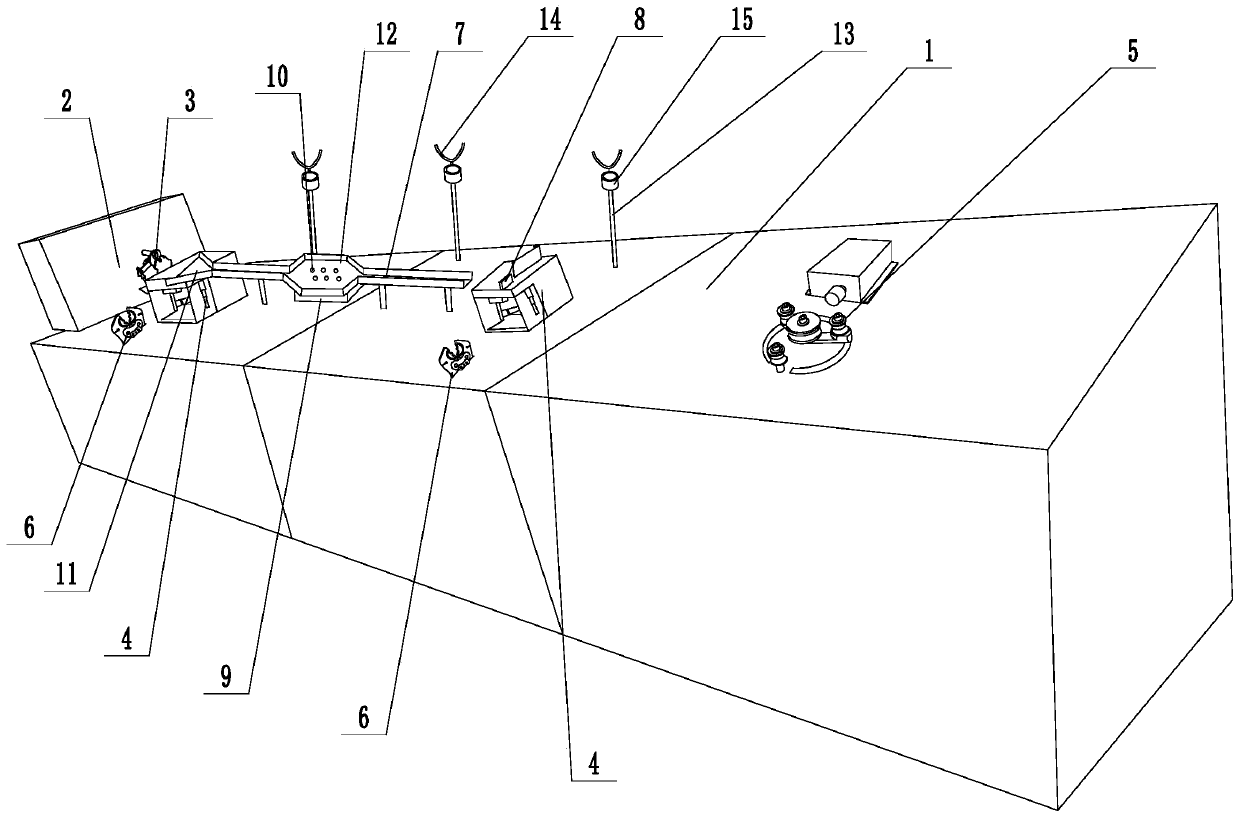

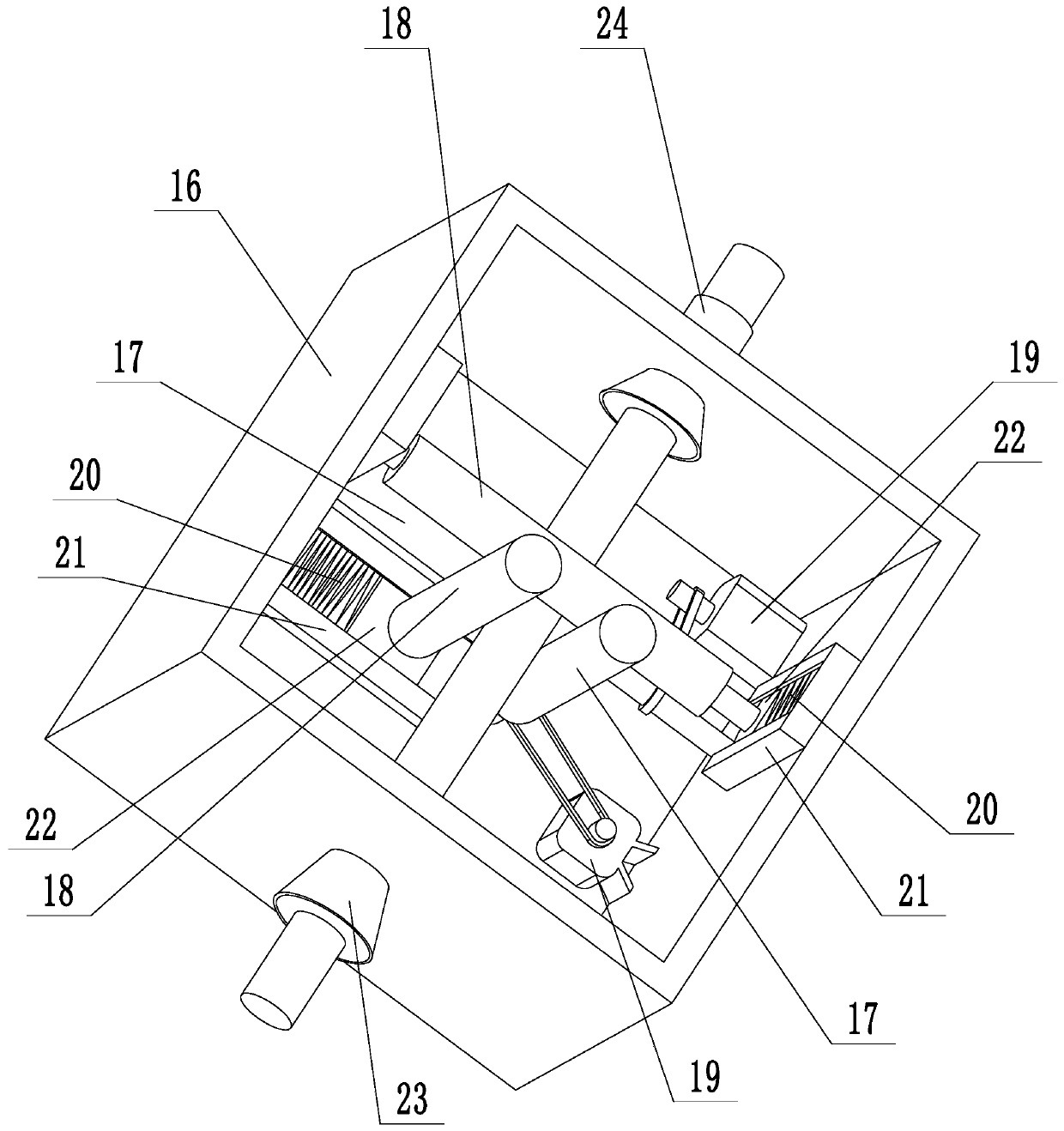

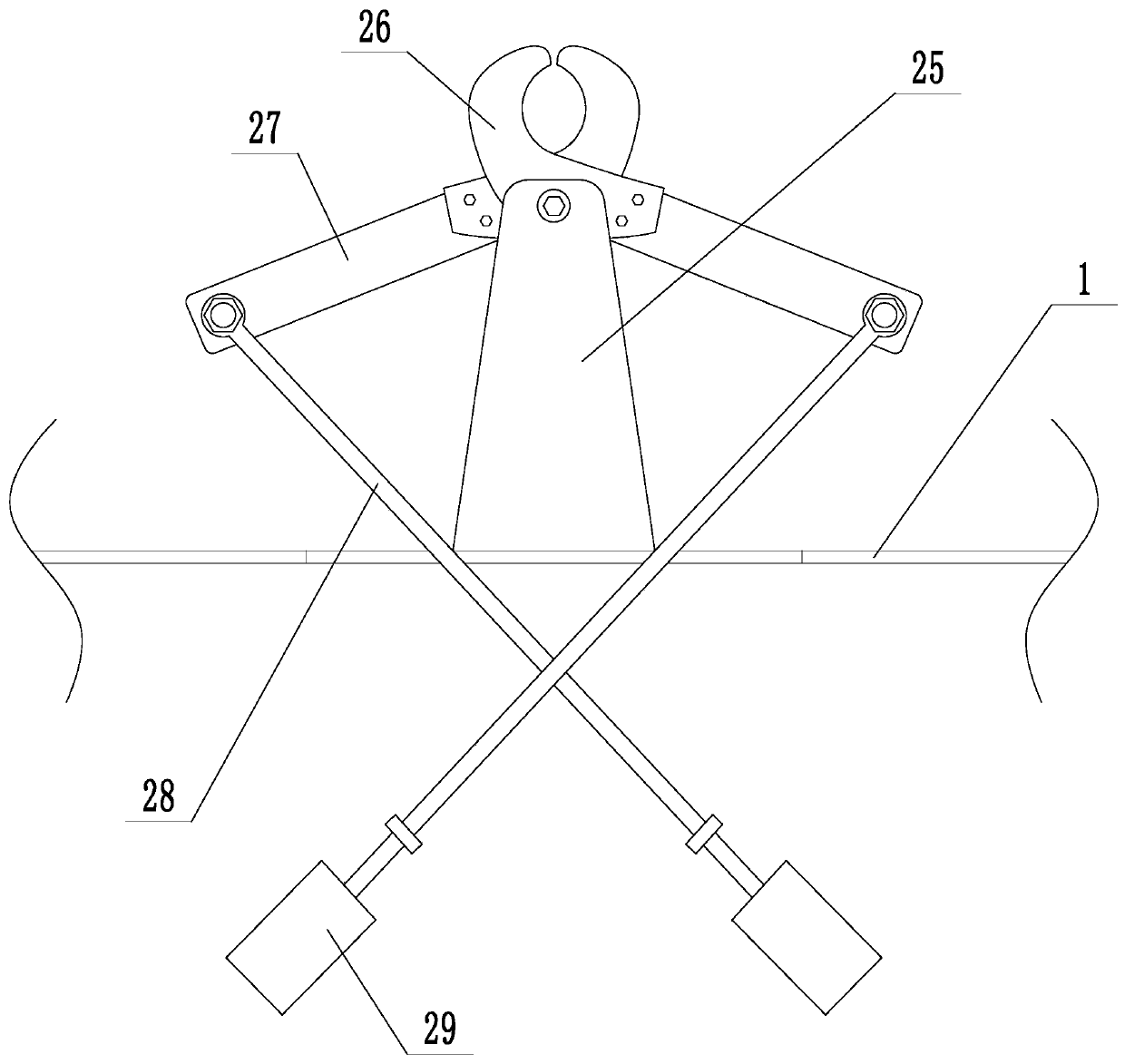

[0031] Embodiment: a drop-out fuse lower lead production table (see attached Figures 1 to 7 ), including workbench 1, which is provided with wire feeding mechanism 2, wire trimming mechanism 3, wire stripping mechanism 4, and wire bending mechanism 5 from left to right. There are two wire stripping mechanisms. The position of the wire mechanism is equipped with a press-fitting mechanism 6, and a wire feeding guide groove 7 is connected between the two wire stripping mechanisms. Device 8, the sensor in place adopts a travel switch, and a cable clip installation block 9 is connected between the wire feeding guide groove and the workbench. inside the clamp mounting block. The wire feeding guide groove is provided with a guide section 11 whose width decreases from left to right toward the end of the wire trimming mechanism, and a wire clamp connecting plate 12 is provided on the wire feeding guide groove corresponding to the wire clamp installation block, and the installation ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com