A 3D printed antibacterial hydrogel repair scaffold and its preparation method

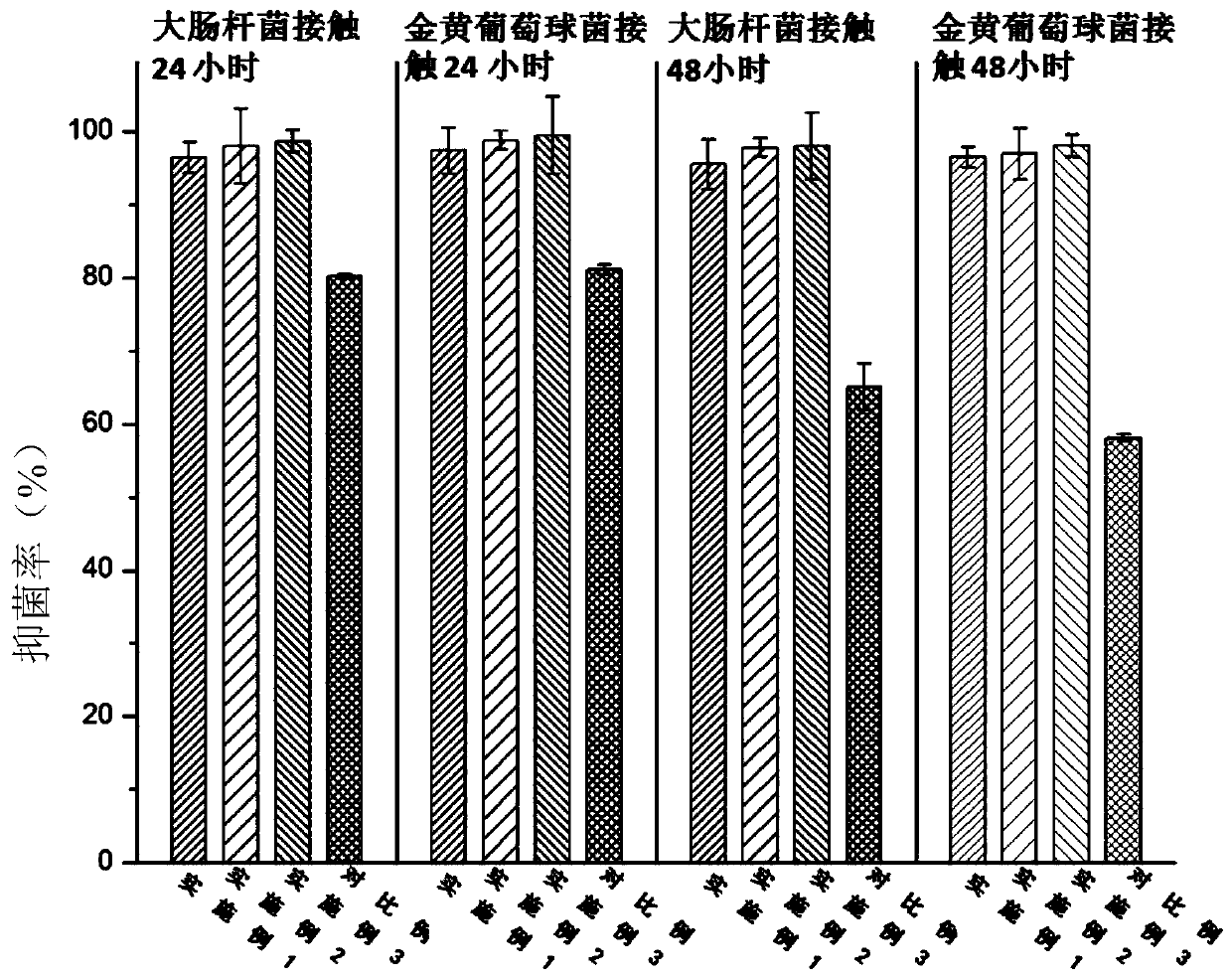

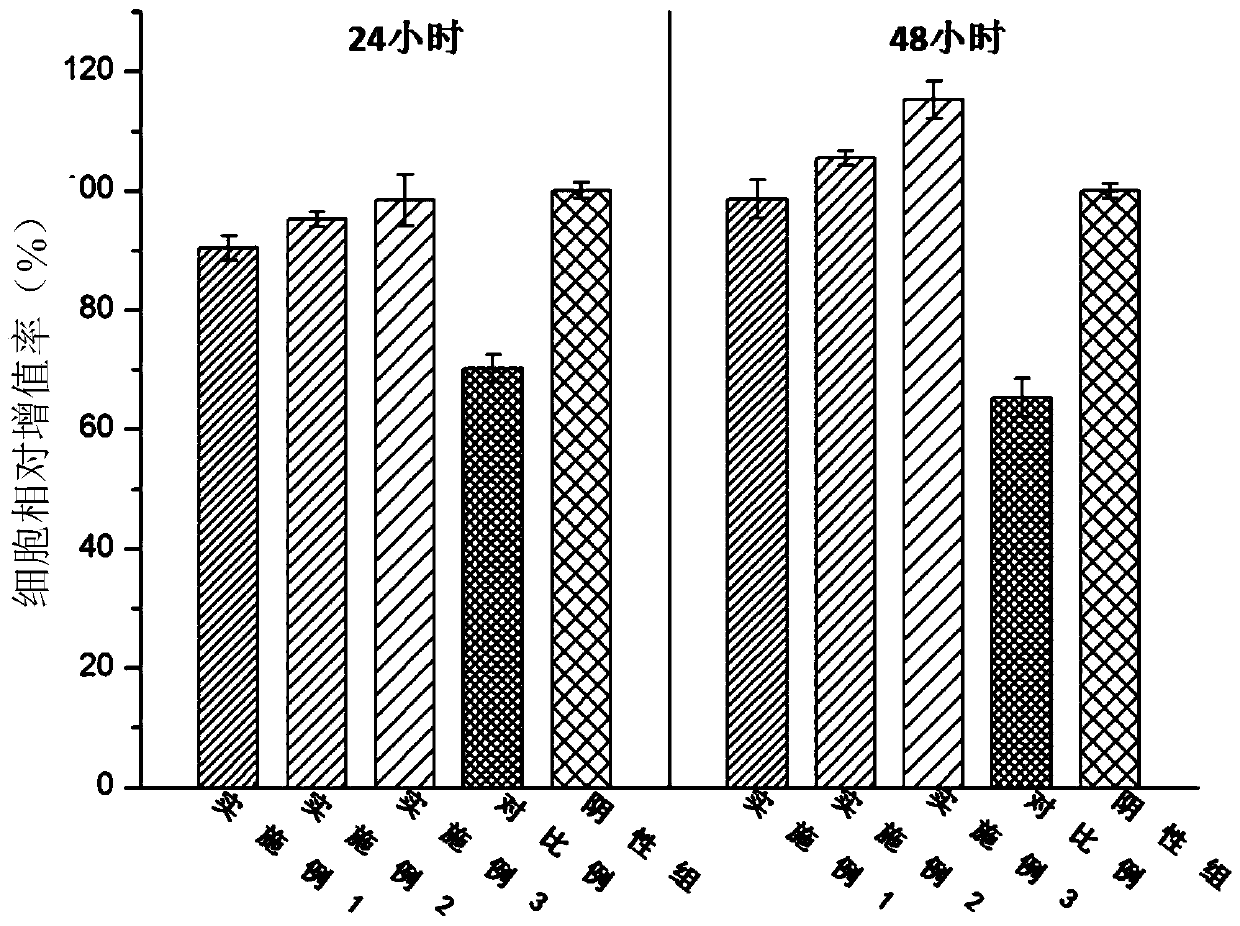

A 3D printing and hydrogel technology, applied in the field of biomedical engineering, can solve the problems of susceptibility to bacterial infection, lack of antibacterial properties, and single function of repairing scaffolds, and achieve suitable vascularization ability, good biocompatibility and antibacterial Performance, the effect of easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] (1) Preparation of methacryloyl sodium hyaluronate: take a certain amount of sodium hyaluronate (1×10 6 ~1.2×10 6 kDa) was dissolved in distilled water to prepare a sodium hyaluronate solution with a mass concentration of 1%, and then adding a NaOH solution with a concentration of 5mol / L to adjust the pH of the sodium hyaluronate solution to 8.5; by mass ratio m sodium hyaluronate: m methacrylic anhydride = 1:7.8 Add methacrylic anhydride, react at 10°C for 24 hours, add it into a dialysis bag (molecular weight cut-off: 14,000) for dialysis with running water for 3 days, and freeze-dry at -80°C to obtain methyl Acrylylated sodium hyaluronate was stored in a -20°C refrigerator for later use.

[0068] (2) Preparation of methacrylated oxidized sodium alginate: dissolving sodium alginate in distilled water to prepare sodium alginate (5×10 6 ~8×10 6 kDa) solution, then add sodium periodate according to the mass ratio m sodium alginate: m sodium periodate=2:1, keep away fr...

Embodiment 1

[0080] The present invention prepares the antibacterial hydrogel repair support according to the above method, wherein: the molecular weight of the sodium hyaluronate used is 1×10 6 kDa; the molecular weight of sodium alginate is 5×10 6 kDa; in the preparation step of the composite printing precursor, the consumption of HA-MA is 20 parts by mass, the consumption of OMA is 20 parts by mass; the dopamine hydrochloride solution of 10mg / mL is 30 parts by volume; the consumption of antimicrobial peptide LL37 is 0.1 parts by mass, The concentration when used was 10 μg / mL; the HA-MA / OMA composite hydrogel treated with polydopamine surface modification was soaked in the antimicrobial peptide LL37 solution and placed in a sterile ultra-clean bench for 12 hours.

Embodiment 2

[0082] The present invention prepares the antibacterial hydrogel repair support according to the above method, wherein: the molecular weight of the sodium hyaluronate used is 1×10 6 kDa; the molecular weight of sodium alginate is 5×10 6 kDa; in the preparation step of the composite printing precursor, the consumption of HA-MA is 20 parts by mass, the consumption of OMA is 40 parts by mass; the dopamine hydrochloride solution of 10mg / mL is 30 parts by volume; the consumption of antimicrobial peptide LL37 is 0.1 parts by mass, The concentration when used was 30 μg / mL; the HA-MA / OMA composite hydrogel treated with polydopamine surface modification was soaked in the antimicrobial peptide LL37 solution and placed in a sterile ultra-clean bench for 18 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

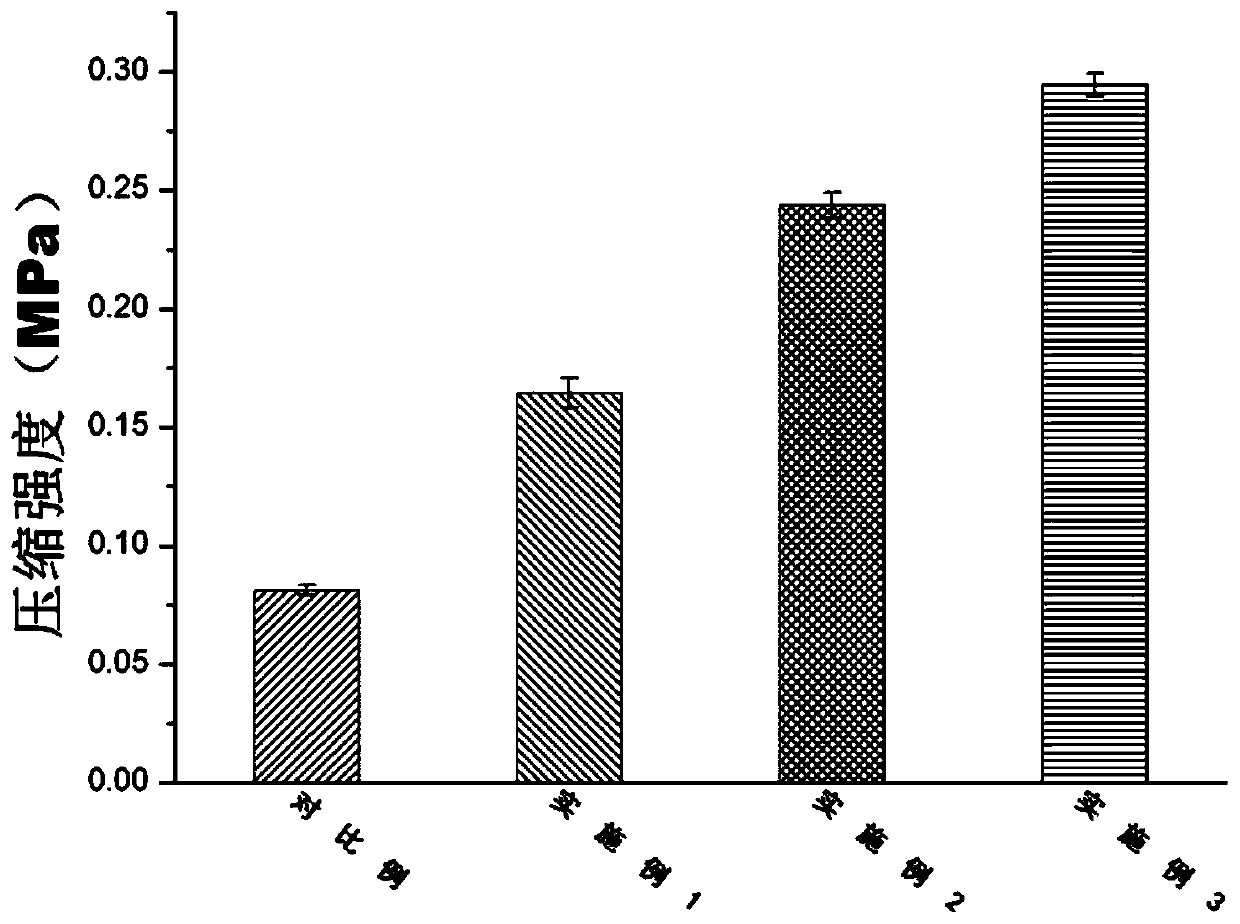

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com