Rice protein negative pressure series crushing and sucking device and using method

A rice protein and suction device technology, applied in grain processing, etc., can solve problems such as environmental damage, unbalanced wind pressure and air volume, and abnormal production, and achieve the effects of protecting the environment and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

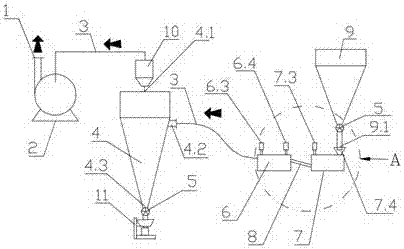

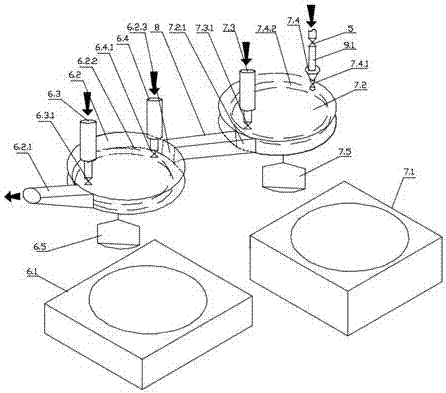

Method used

Image

Examples

Embodiment 1

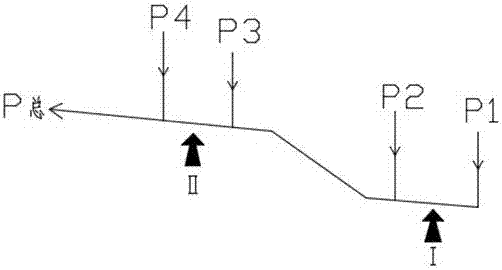

[0048] Example 1: When the system enters the working state, the material volume is 3m³ / h. Adjust P1=2500m³ / h, P2=500m³ / h, P3=1800m³ / h, P4=1600m³ / h, the primary and secondary crushing motor currents are 48A and 50A respectively, both of which are less than the rated current of 60A, and there is no overflow at the suction port powder situation.

Embodiment 2

[0049] Example 2: When the system enters the working state, the material volume is 3m³ / h. Adjust P1=3000m³ / h, P2=500m³ / h, P3=1500m³ / h, P4=1400m³ / h, the primary and secondary crushing motor currents are 62A and 55A respectively, exceeding the rated current of 60A, the motor is overloaded, and the suction port is not Powder spillage occurs.

Embodiment 3

[0050] Example 3: When the system enters the working state, the material volume is 3m³ / h. Adjust P1=1600m³ / h, P2=1600m³ / h, P3=1600m³ / h, P4=1600m³ / h, the primary and secondary crushing motor currents are 45A and 43A respectively, both of which are less than the rated current of 60A. There is powder overflow at the suction port of the stage crushing. When the material is sucked by negative pressure, the air flow at the P1, P2, P3, and P4 air collection places plays a vital role in the transmission. The adjustment of each air volume accounts for the total air volume through statistical optimization. : P1 accounts for about 4 / 10, P2 accounts for about 1 / 10, P3 accounts for about 3 / 10, and P4 accounts for about 2 / 10. The above-mentioned structural scheme is adopted for realizing the adjustable air volume.

[0051] For the relevant parameters in the above three embodiments, see the embodiment summary table for details.

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com