Casting method of casting of gas feeding end of high pressure outer cylinder of thick-wall gas turbine

A technology of high-pressure outer cylinder and air intake end, which is applied to casting molding equipment, molds, mold components, etc., and can solve problems such as shrinkage cavities, shrinkage porosity, and many hot spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

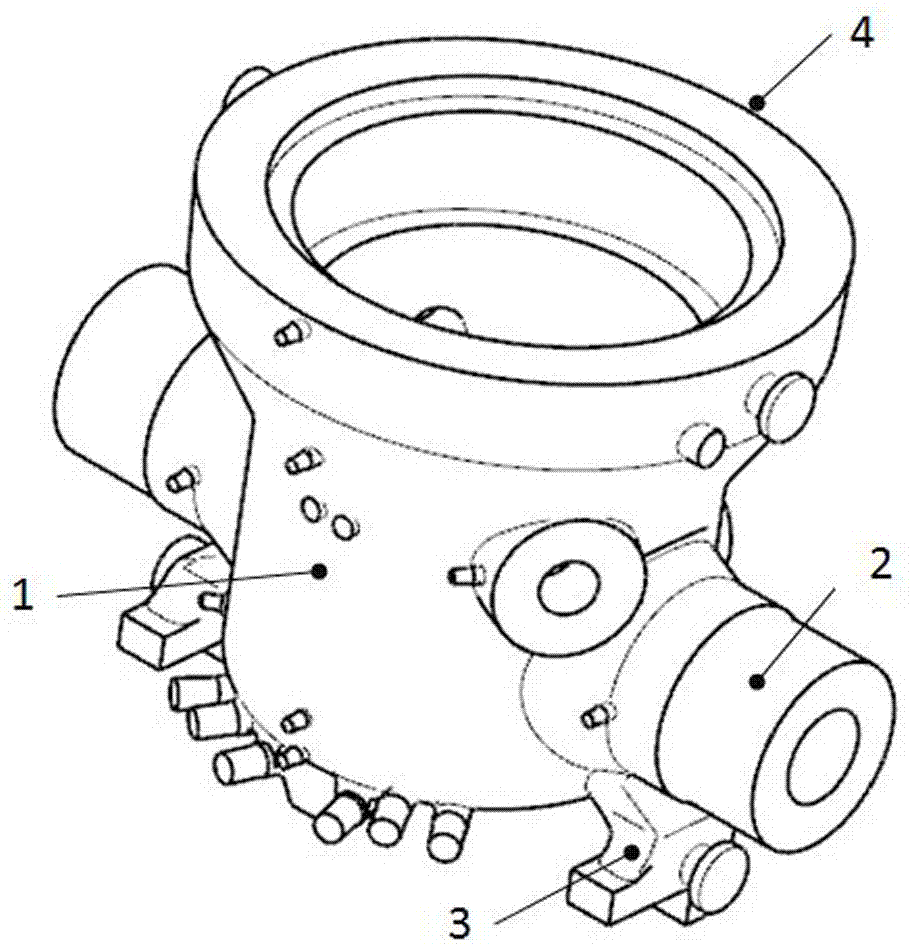

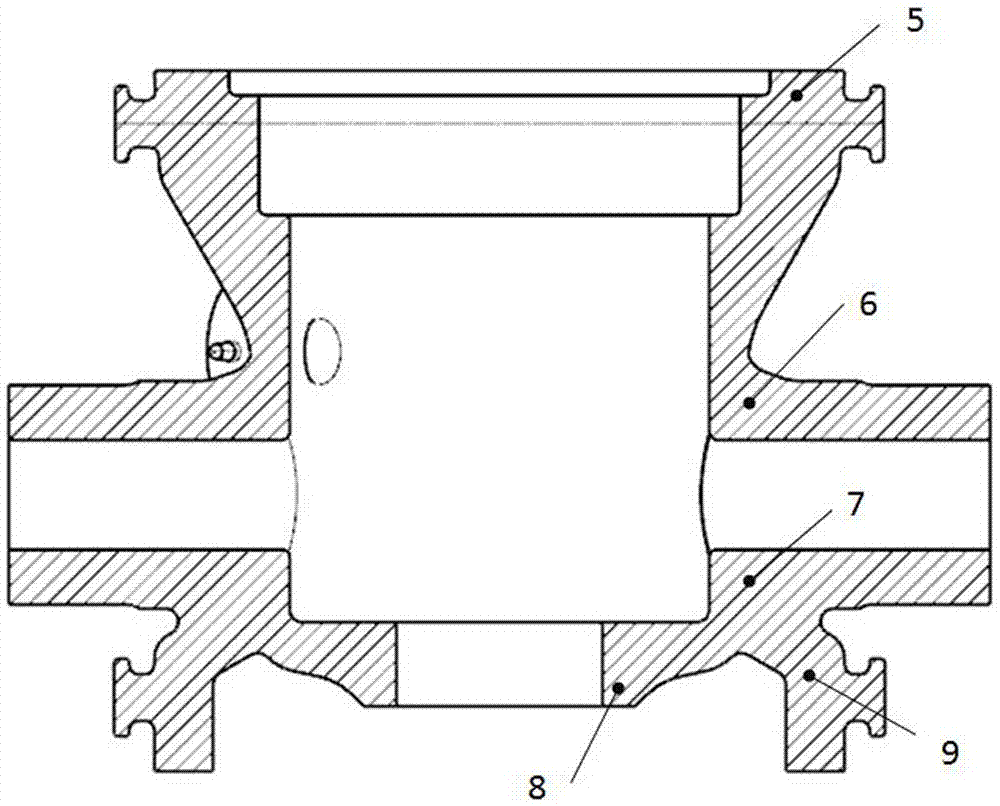

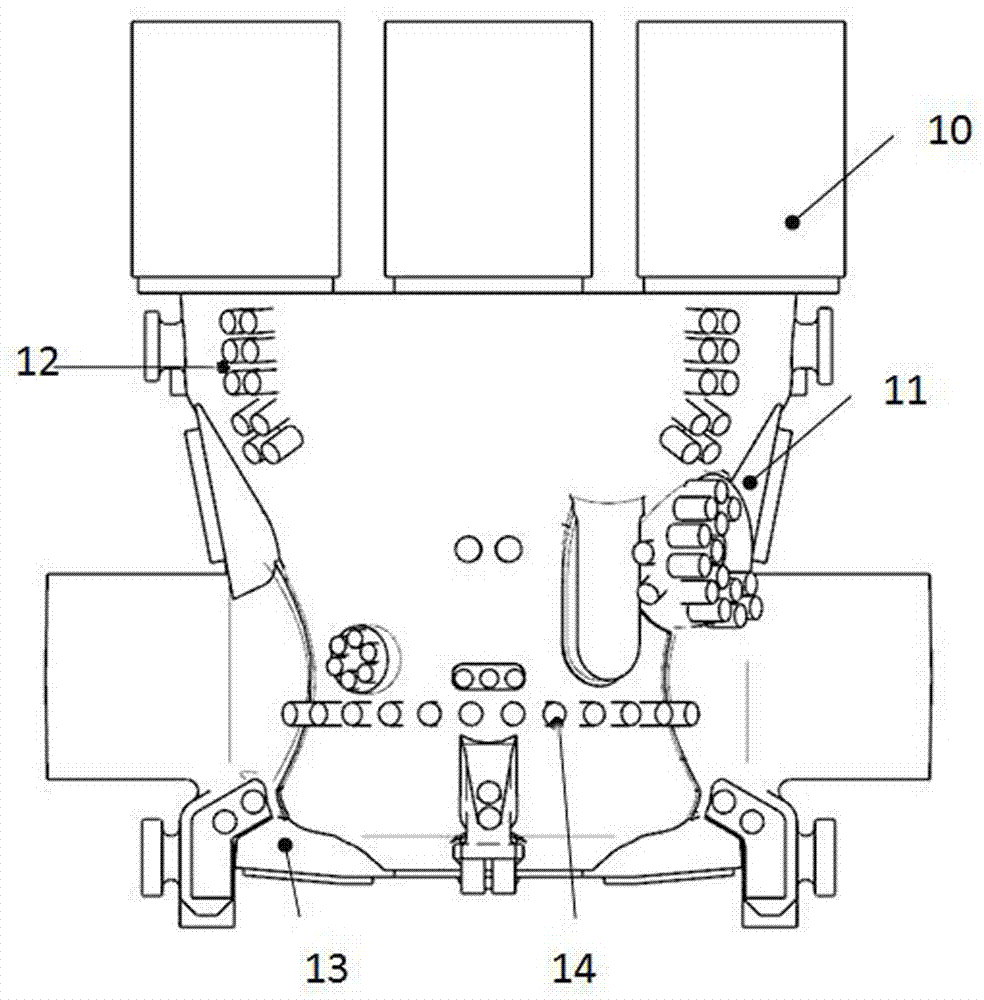

[0022] The invention provides a casting method for the casting of the intake end of the high-pressure outer cylinder of a thick-walled gas turbine, such as image 3 — Figure 5 As shown, according to the structural characteristics of the cylinder body, it mainly includes the following process:

[0023] First determine the casting direction of the casting: when pouring, the flange end 4 of the casting is horizontally upward, and the corresponding end of the cat's claw 3 is downward. Then carry out the riser and subsidy design: set several open risers on the upper side of the flange end 4 for feeding the heat section 15, and set the dark riser 15 inside the step hole at the gas outlet end of the cylinder body 1 for directly feeding the heat Section 4 8; Subsidy 1 11 is respectively provided at the transition angle above the connection between the two horizontal horizontal tubes 2 of the casting and the outer wall of the cylinder body 1 to form the feeding channels of the hot se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com