Accelerator cap structure based on reducing rejection rate

A technology of accelerator and cap structure, which is applied to casting molding equipment, casting molds, cores, etc., can solve the problem of small feeding capacity of bottom casting risers, uneven casting riser allowance, and unqualified parts air tightness, etc. problems, to achieve the effect of improving machining speed and quality, improving product quality and yield, and avoiding shrinkage cavities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] as attached figure 1 to attach Figure 5 Shown:

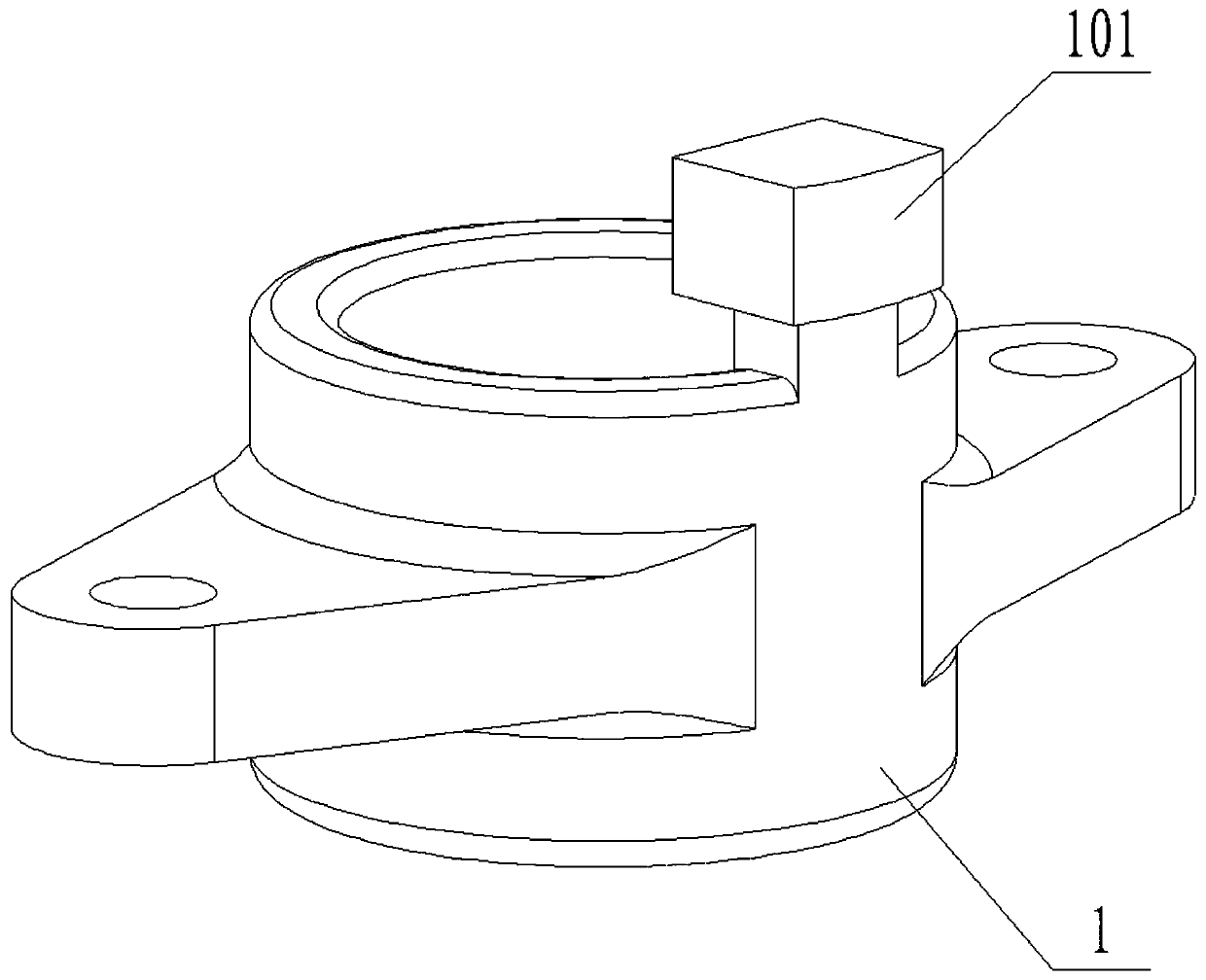

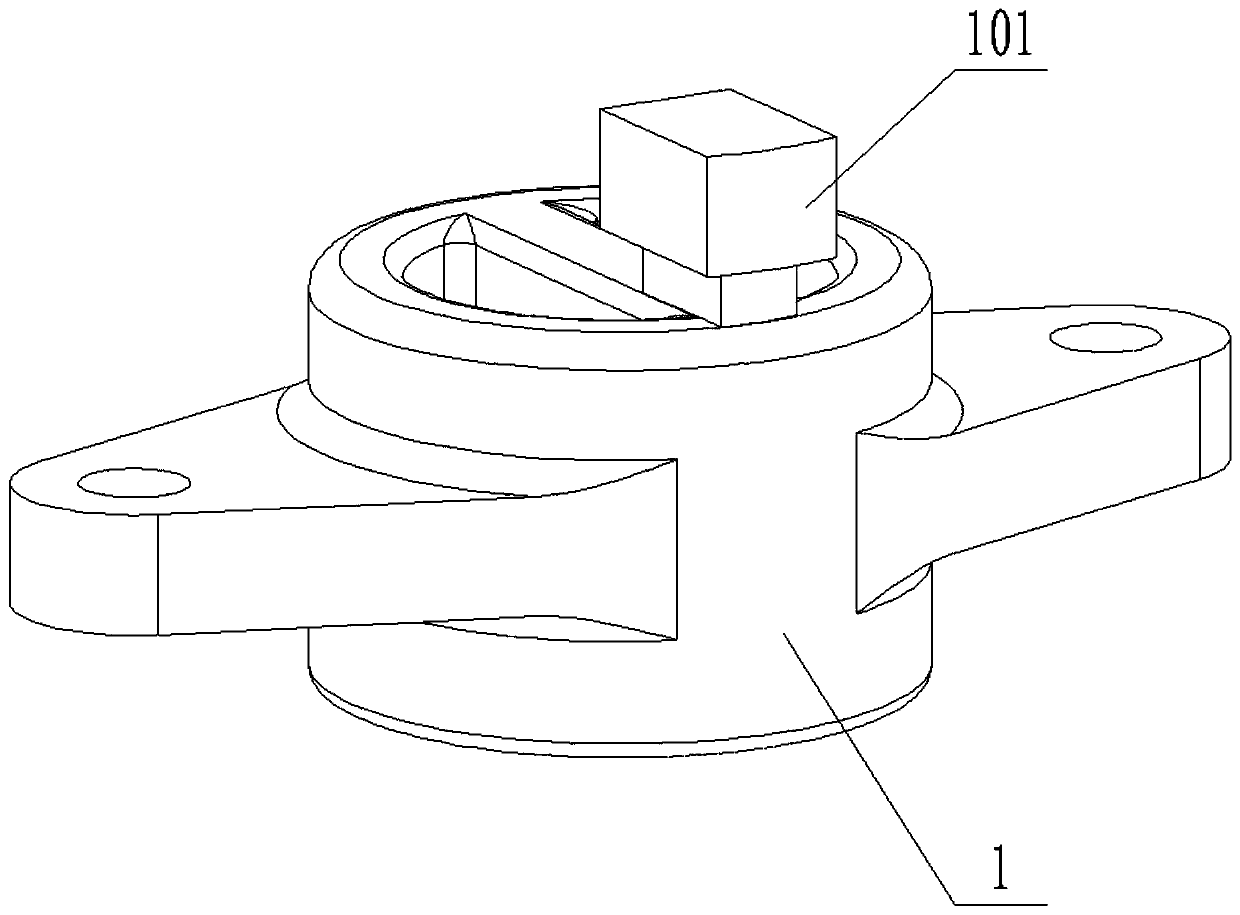

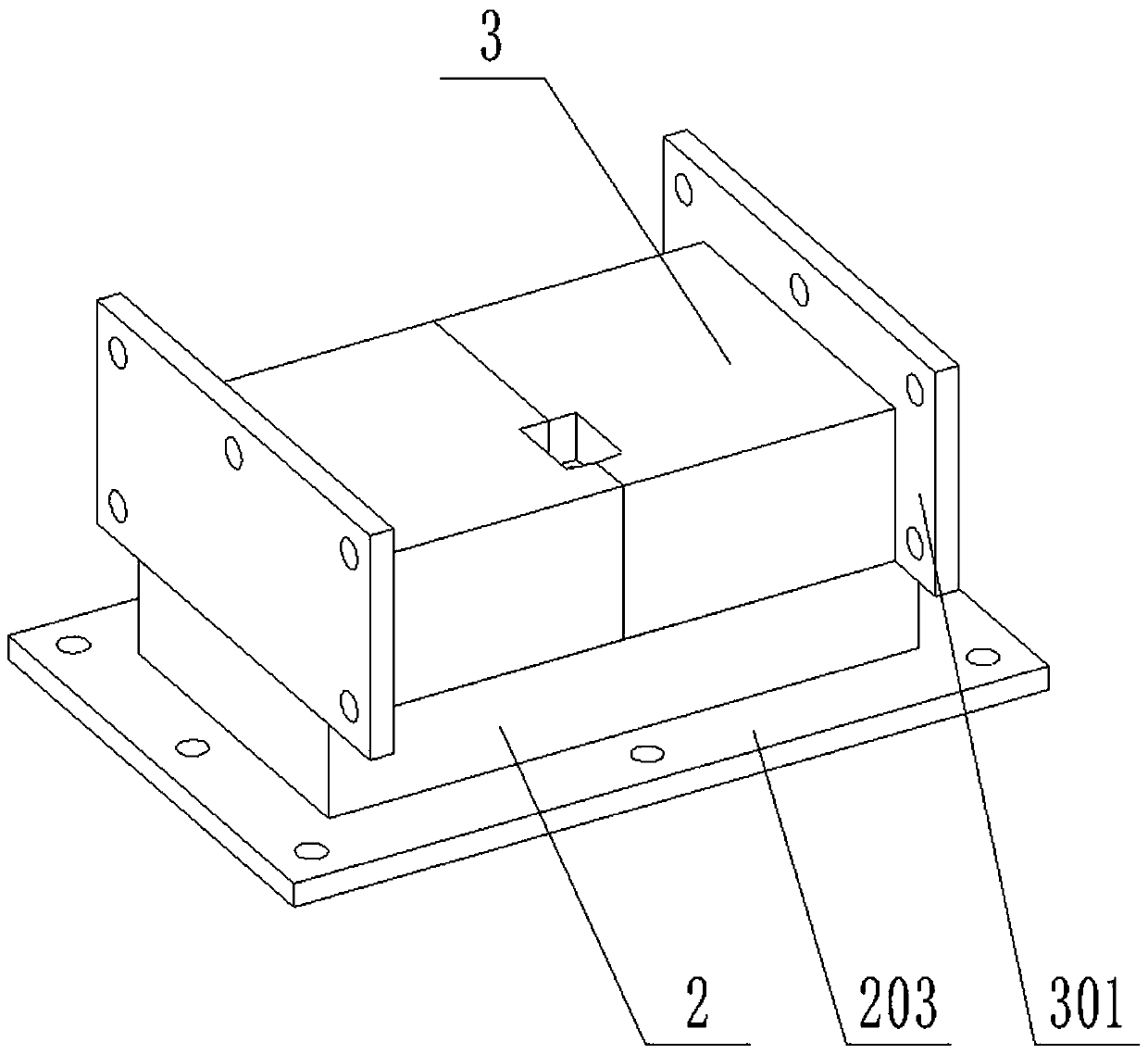

[0028] The present invention provides a accelerator cap structure based on reducing the scrap rate, including accelerator cap 1, casting riser 101, bottom mold 2, cooling copper rod 201, cooling iron 202, bottom flange 203, side mold 3 and side method Lan 301; the casting mold of the accelerator cap 1 is composed of two sets of side molds 3 and a set of bottom molds 2; the side molds 3 are located on the left and right sides above the bottom mold 2.

[0029] Wherein, the top of the booster cap 1 is provided with a set of casting risers 101, the casting risers 101 are located at the handle of the booster cap 1 and avoid rounded corners, changing the traditional 1. Setting it on the mating surface will easily cause shrinkage cavity on the mating surface and cause leakage accidents in assembly. At the same time, the casting riser 101 is set at the handle of the accelerator cap 1. The volume of the casting riser 101 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com