Device for producing GH4169 nickel-based superalloy

A nickel-based superalloy, GH4169 technology, applied in the field of nickel-based superalloy production equipment, can solve the problems of uneven product structure and performance, affecting the quality of alloy ingots, poor uniformity of magnetic field distribution, etc., to reduce surface and subcutaneous slag inclusions , improve surface and internal quality, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

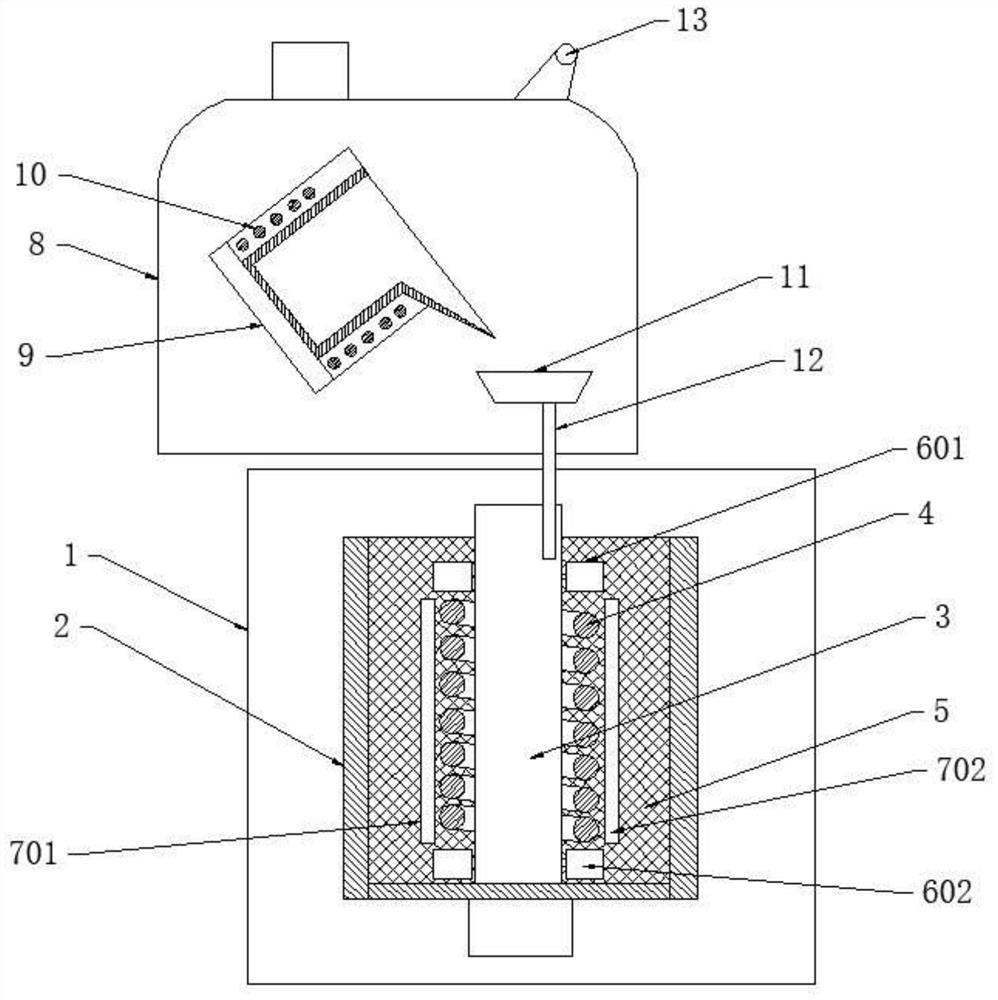

[0040] combine Figure 1-Figure 4 , the invention provides a device for producing GH4169 nickel-based superalloy, including an ingot mold chamber 1;

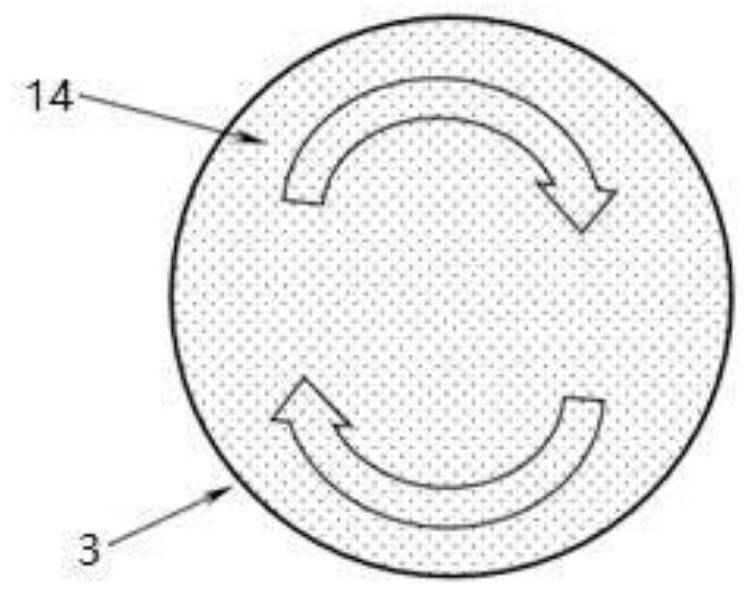

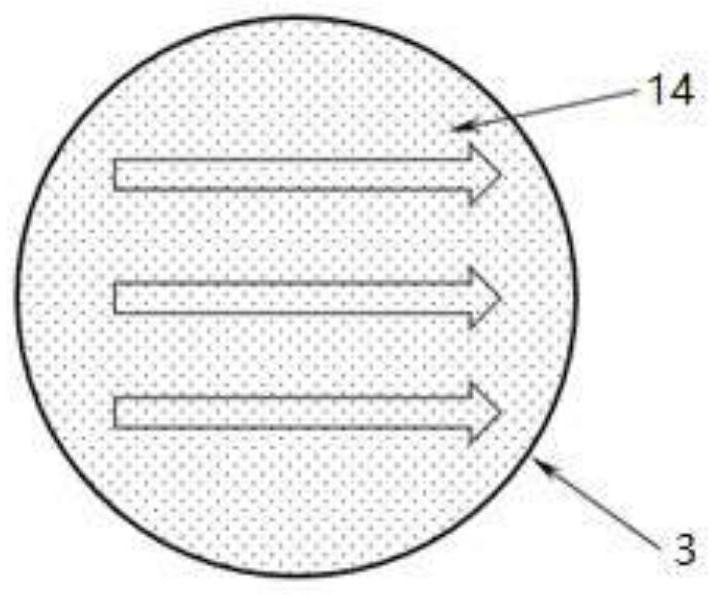

[0041] A centrifugal device, a circular magnetic field generator, a parallel magnetic field generator and a traveling wave magnetic field generator are installed in the ingot mold chamber 1;

[0042] The centrifugal device includes a centrifugal bucket 2, the centrifugal bucket 2 is connected with a transmission mechanism, and the transmission mechanism is connected to a motor, wherein, the transmission mechanism and the motor are both existing technologies, and will not be described in detail here; the motor drives the transmission mechanism to rotate, and the transmission mechanism drives the centrifugal bucket 2 turn;

[0043] An ingot mold 3 is installed in the centrifugal barrel 2 of the centrifugal device, and the ingot mold 3 is detachably connected with the centrifugal barrel 2; the ingot mold 3 and the centrifugal barr...

Embodiment 2

[0057] Use the device of embodiment 1, produce GH4169 nickel base superalloy, process is as follows:

[0058] (1) Material preparation: all raw materials are dried and preheated in an electric furnace at 150-200°C for about 6 hours to remove water vapor in the raw materials;

[0059] (2) Smelting: Put the dried raw materials into the crucible of the smelting chamber, set the power of the induction heating coil to 25kw, and the heating temperature to 1450°C; the smelting is divided into two steps. Smelting of raw materials with high melting point and low volatility; control the vacuum degree of the smelting chamber to ≤5Pa, stop the vacuum degree control until it is completely melted; then, pass Ar into the smelting chamber, and stop the ventilation when the smelting chamber reaches 0.05MPa. Put low melting point and volatile raw materials into the crucible for the second step of melting;

[0060] (3) Molding: Use the centrifugal device, annular magnetic field generator, trave...

Embodiment 3

[0062] The difference from Example 2 is that in step (2), the dried raw material is put into the crucible of the melting chamber, the power of the induction heating coil is set to 25kw, and the heating temperature is set to 1400°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com