Gas condensate separation device and technical method

A separation device and process method technology, applied in the petroleum industry, hydrocarbon oil distillation control/regulation, hydrocarbon distillation and other directions, can solve the problems of short processing flow, limited investment capacity and management level, etc., to achieve low overall cost and reduce one time The effect of cost-effective investment and shortening of the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

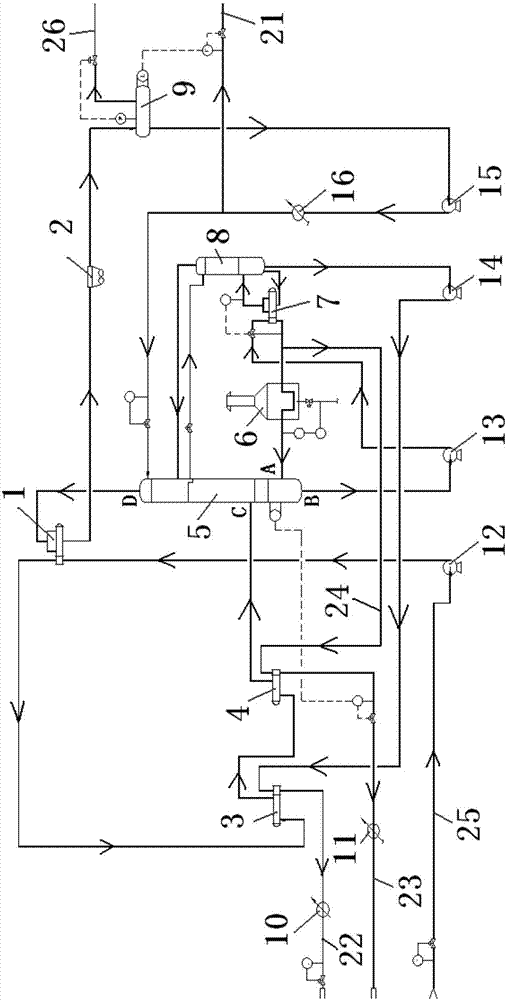

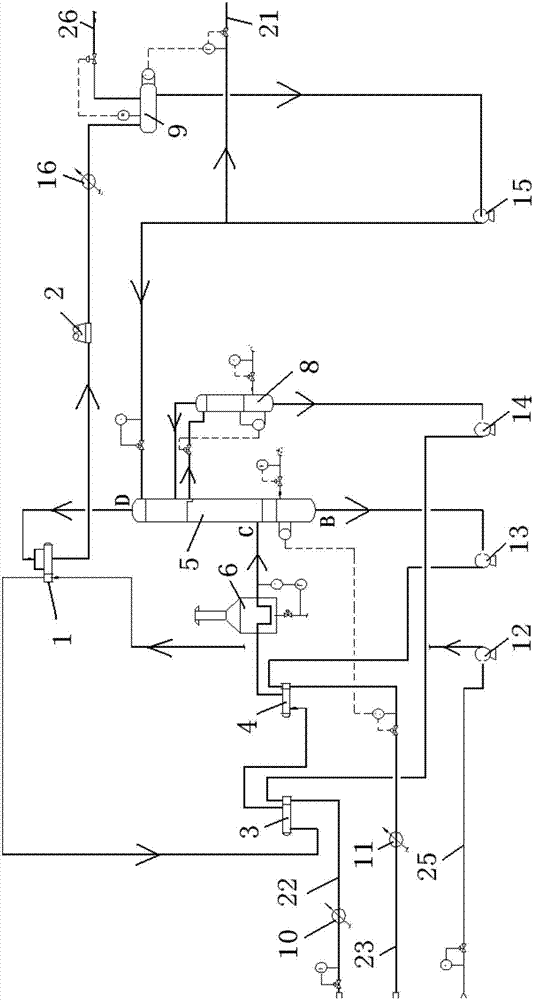

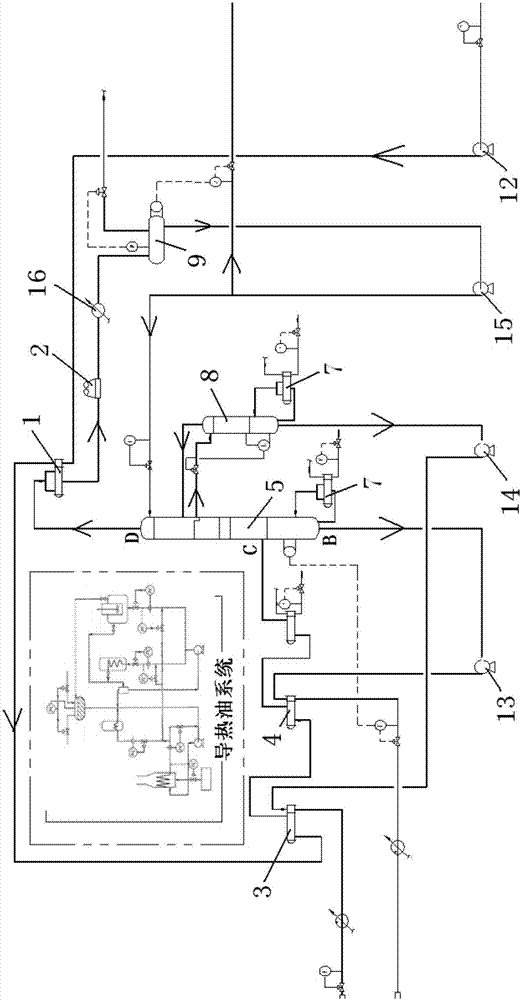

[0022] A condensate oil separation device, comprising an atmospheric tower 5, an atmospheric tower top gas heat exchanger 1, an atmospheric tower top air cooler 2, a tower top reflux tank 9, a tower top reflux pump 15, and a tower top naphtha cooling Device 16, atmospheric tower bottom oil pump 13, side stripper reboiler 7, side stripper 8 and atmospheric tower reboiler 6; atmospheric tower bottom oil pump 13, side stripper reboiler 7 and side line The stripping tower 8 is connected successively, and the bottom oil pump 13 of the atmospheric tower is also connected with the bottom oil outlet B of the atmospheric tower 5, the air heat exchanger 1 at the top of the normal pressure tower, the air ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap