A method for increasing the concentration of end product of pipeline transportation coal water slurry

A technology for product concentration and water transportation, applied in fuel additives, liquid carbon-containing fuels, petroleum industry, etc., can solve problems such as insufficient optimization of coal slurry particle size distribution, low efficiency, and increased oxygen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] This embodiment provides a method for improving the concentration of the terminal product of pipeline transportation coal-water slurry. The low-concentration pipeline transportation coal slurry and the raw coal used in this embodiment are all low-rank coals in Shenmu, Shaanxi, and the analysis water Mad is 4.5wt %, total water Mt is 15.3wt%, ash Aad is 7.9wt%, volatile Vdaf is 28.8wt%.

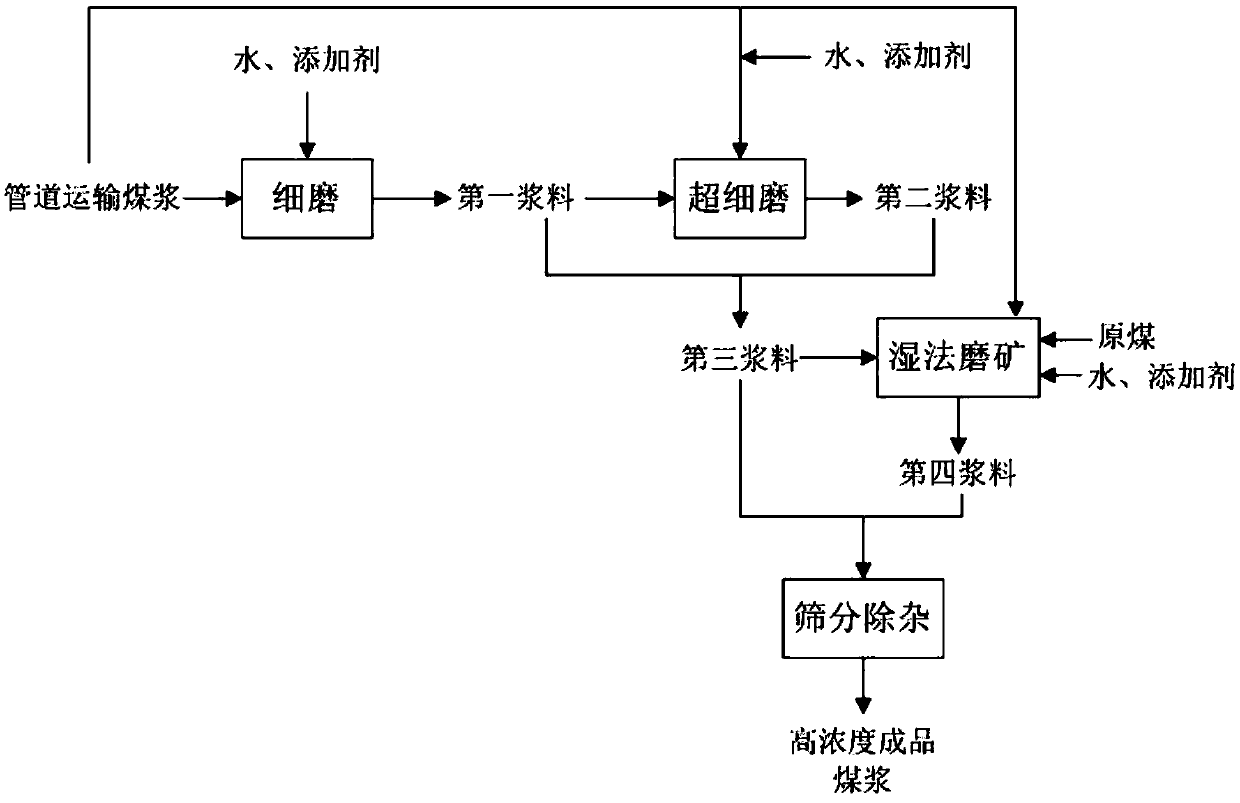

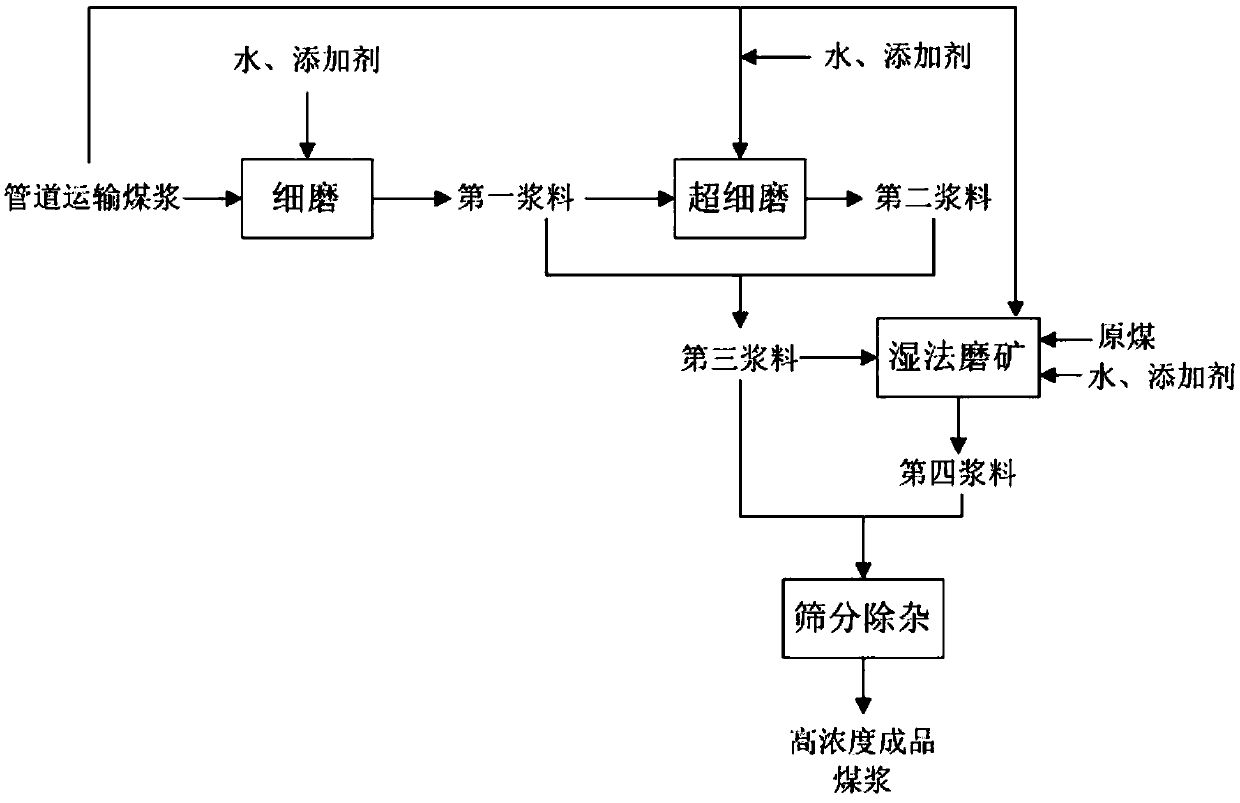

[0067] Such as figure 1 As shown, the method includes the following steps:

[0068] (1) Select a low-concentration pipeline coal slurry with a concentration of 50wt%, the largest particle ≤ 2.4mm, and the fluidity index of the coal slurry is 13cm. The fluidity index of the coal slurry is tested with reference to the cement "GB / T8077-2012 Concrete Admixture Homogeneity According to the test method of "fluidity of cement slurry" in the industry standard of "Test Method", the stability of coal slurry is 20% of the water separation rate after being placed for 2 hours;

[0069] (2) Mix the...

Embodiment 2

[0075] This embodiment provides a method for improving the concentration of the terminal product of pipeline transportation coal-water slurry. The low-concentration pipeline coal slurry and the raw coal used in this embodiment are all low-rank coals in the Ordos area of Inner Mongolia, and the analysis water Mad is 5.5wt %, total water Mt is 18.5wt%, ash Aad is 10.5wt%, volatile Vdaf is 25.7wt%.

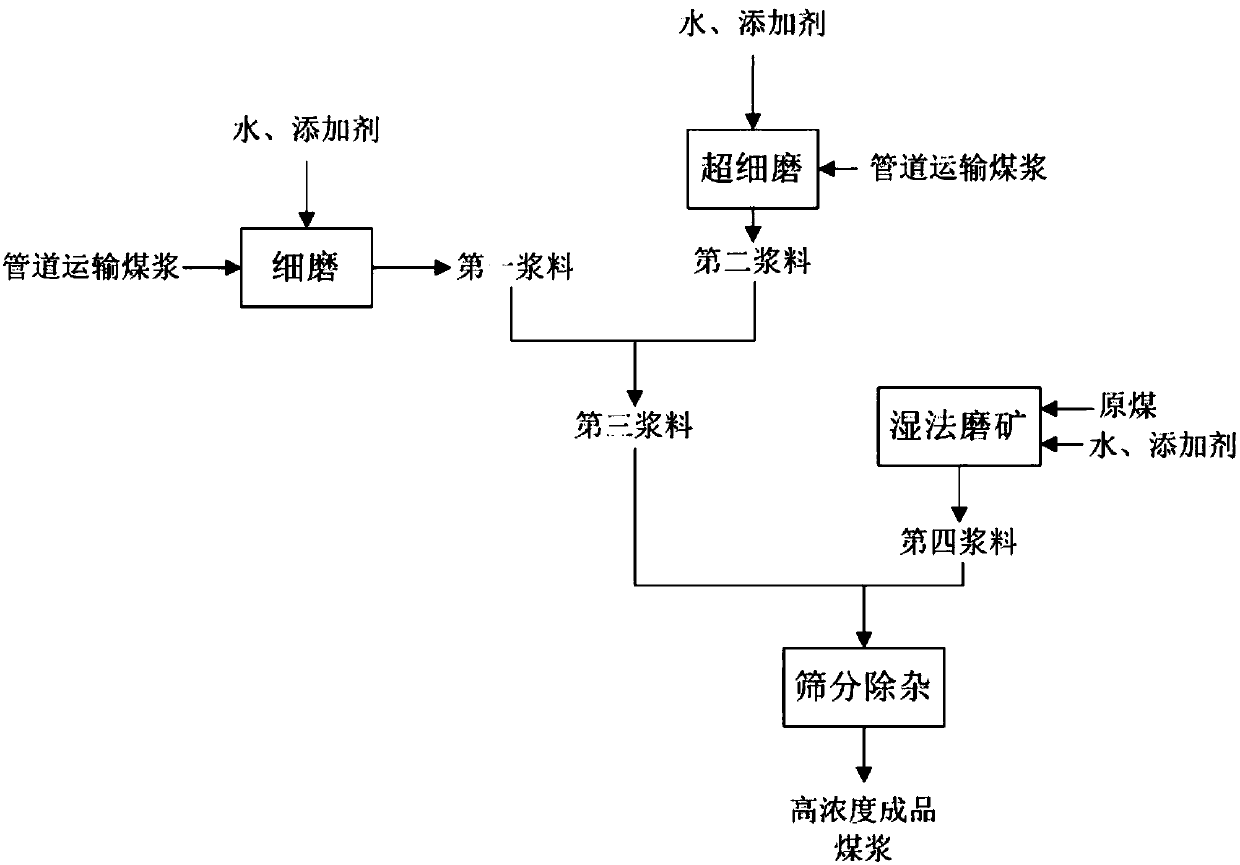

[0076] Such as figure 2 As shown, the method includes the following steps:

[0077] (1) Select a low-concentration pipeline coal slurry with a concentration of 45wt%, the largest particle is ≤2mm, and the fluidity index of the coal slurry is 14cm. The fluidity index of the coal slurry is tested with reference to the cement "GB / T8077-2012 Concrete Admixture Homogeneity Test Method "in the industry standard "Cement slurry fluidity" test method, the stability of coal slurry is 25% of the water separation rate after being placed for 2 hours;

[0078] (2) Mix the low-concentration pi...

Embodiment 3

[0084] This embodiment provides a method for improving the concentration of the terminal product of pipeline transportation coal-water slurry. The low-concentration pipeline coal slurry used in this embodiment and the raw coal used are all low-rank coals in the Ordos area of Inner Mongolia. Its composition is the same as that in Example 2. same.

[0085] Described method is with reference to the method in embodiment 2, and difference is: in the step (1), choosing concentration is the low-concentration pipeline coal slurry of 35wt%; The concentration of the first slurry prepared in the step (2) is 30wt%, finely ground The proportion of particles with a particle size of ≤75 μm is 60 wt %; the mass concentration of the second slurry prepared in step (3) is 30 wt %, wherein the proportion of particles with a particle size of ≤ 75 μm is 80 wt %.

[0086] In the high-concentration finished coal slurry prepared in this example, the mass concentration of the finished coal slurry is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com