An opener

An opening machine and opening roller technology, which is applied in the textile field, can solve the problems of inconvenient loading and unloading of opening rollers, and achieve the effects of improving loading and unloading efficiency, accurate positioning and high opening efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0026] Furthermore, as a specific implementation of an opener provided by the present invention, the included angle α is 10°-30°.

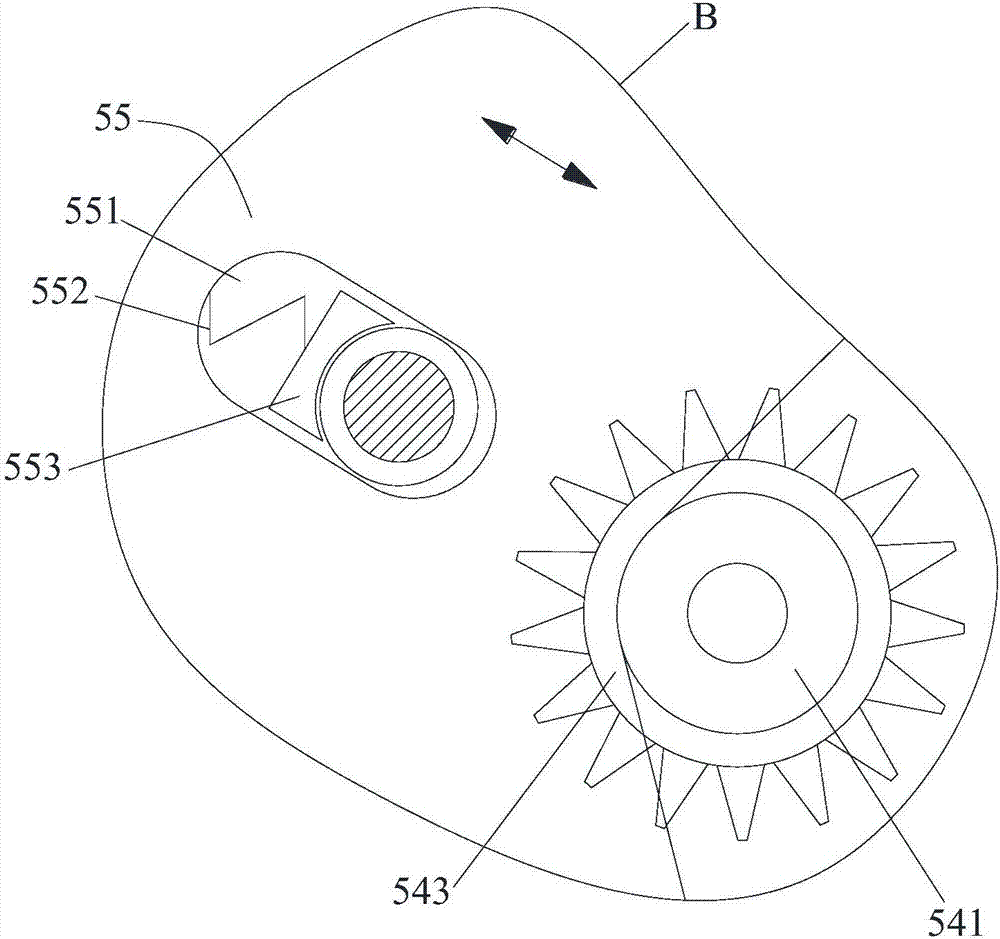

[0027] Further, see Figure 4 , as a specific implementation of the opening machine provided by the present invention, a first fixing plate 35 is provided on the side end surface of the plate body 322, and the inner side plate surface of the first fixing plate 35 does not protrude from the inner side of the plate body 322. Plate surface, the side end surface of roller body 31 is provided with the second fixed plate 36 corresponding with first fixed plate 35, the outer plate surface of second fixed plate 36 does not protrude from the outer surface of roller body 31, the first fixed plate 35 It is connected with the second fixing plate 36 through locking bolts 37 that can pass through the first fixing plate 35 and the second fixing plate 36 . After the needle plate 32 and the roller body 31 are plugged in place, the fixing holes on the first fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com