Edge cutting device for loom

A weaving machine and trimming technology, which is applied in the direction of weaving auxiliary equipment, textiles, textiles and papermaking, etc., can solve the problems that the height position cannot be adjusted, the effect of trimming is affected, and the textile slips, etc., and the structure is simple and convenient. The effect of edge trimming and reducing horizontal error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

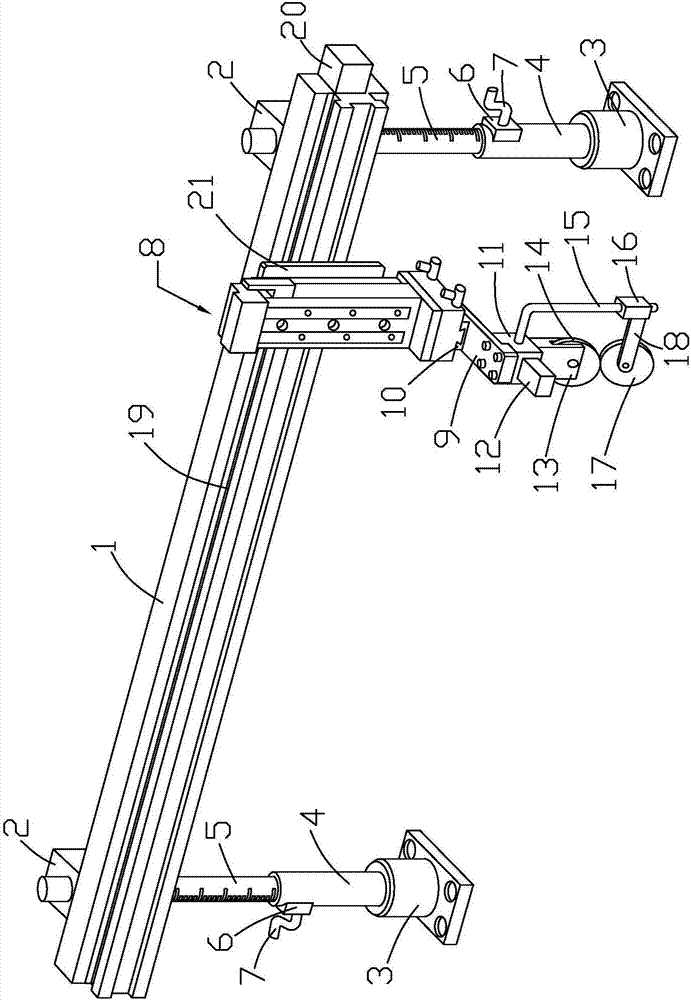

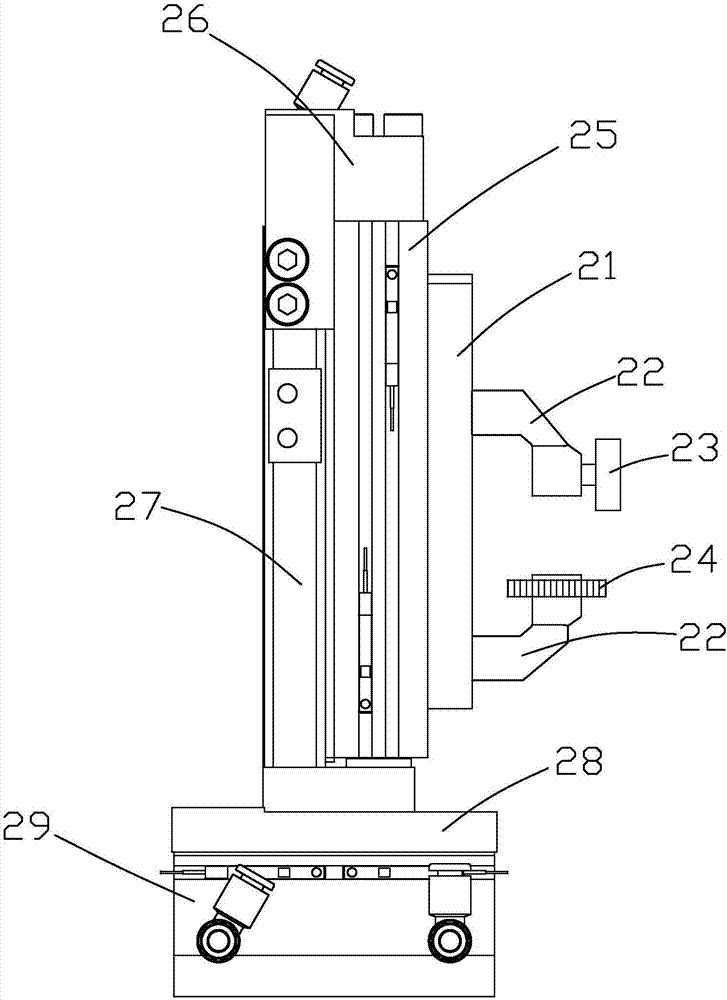

[0026] Such as Figure 1 to Figure 4 As shown, it is a kind of trimming device for loom of the present invention, comprises crossbeam 1, support mechanism, support plate 21, lifting mechanism 8 and trimming mechanism, and support mechanism is fixedly connected to the two ends of crossbeam 1, and support mechanism comprises Positioning block 2, base 3, fixed rod 4 and telescopic rod 5, positioning block 2 is fixedly connected on beam 1, fixed rod 4 is fixedly connected on base 3, positioning block 2 is connected to fixed rod 4 through telescopic rod 5, fixed rod 4 There is a power mechanism between the telescopic rod 5, and the power mechanism can drive the telescopic rod 5 to move up and down along the fixed rod 4, and then adjust the height position of the crossbeam 1, so that the trimming mechanism can move and cut within the set range. There is a scale on the top, and the design of the scale can improve the adjustment accuracy of the telescopic rod 5, thereby enabling the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com