Yarn feeding control method of circular-weft knitting machine

A circular knitting machine and control method technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve problems such as troublesome wiring, loose weaving structure, yarn disorder, etc., achieve fast and timely actions, and ensure stability , Yarn tidy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

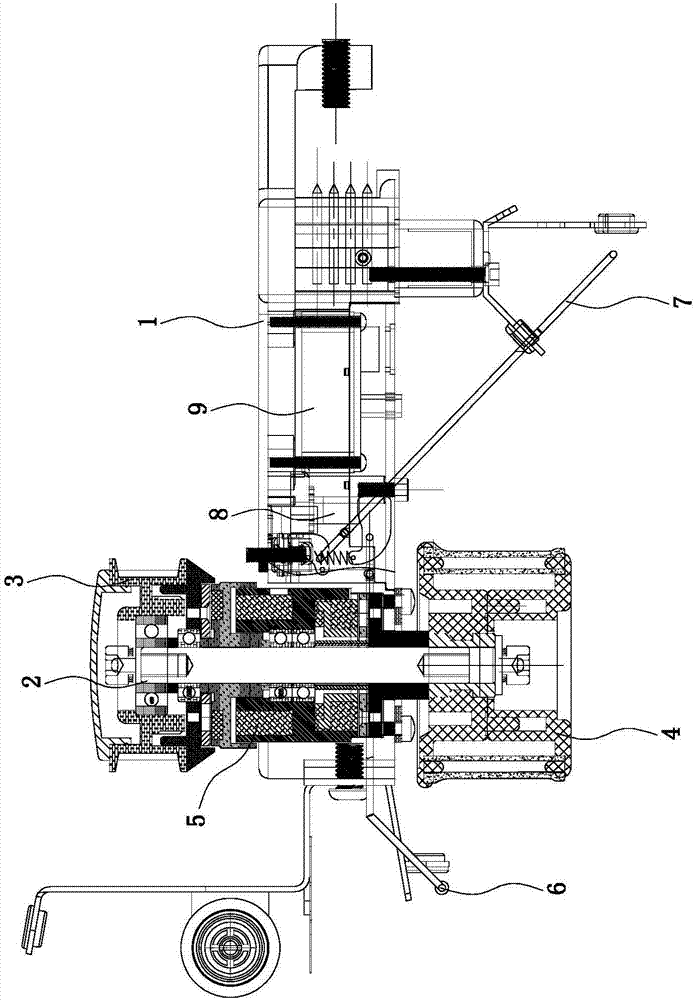

[0014] Attached below figure 1 The present invention is further described.

[0015] Such as figure 1 As shown, it is a yarn feeder, which includes a body 1 and a transmission shaft 2 disposed on the body 1, a synchronous wheel 3 disposed on the transmission shaft 2, a wire transmission wheel 4 disposed on the transmission shaft 2, and a The clutch brake 5 on the body 1, the front probe rod 6 and the rear probe rod 7 on the body 1, and the photoelectric sensor 8 on the body 1, when the clutch brake 5 is in the clutch state, press the transmission wheel 4 , make it stop, when the clutch brake 5 is energized, the clutch brake 5 is engaged, thereby unclamping the transmission wheel 4, and the transmission wheel 4 realizes normal operation.

[0016] According to the above-mentioned yarn feeder, the first embodiment provides a method for controlling yarn feeding of a circular knitting machine, comprising the following steps:

[0017] When the yarn needs to be changed according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com