Displacement enlarging friction damper and assembly construction process

A friction damper, a large-scale technology, applied in the direction of building types, building components, earthquake resistance, etc., can solve the problems of affecting building use functions, low lever transmission efficiency, inconvenient installation and construction, etc., to achieve easy maintenance and replacement, stable working performance, Create handy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

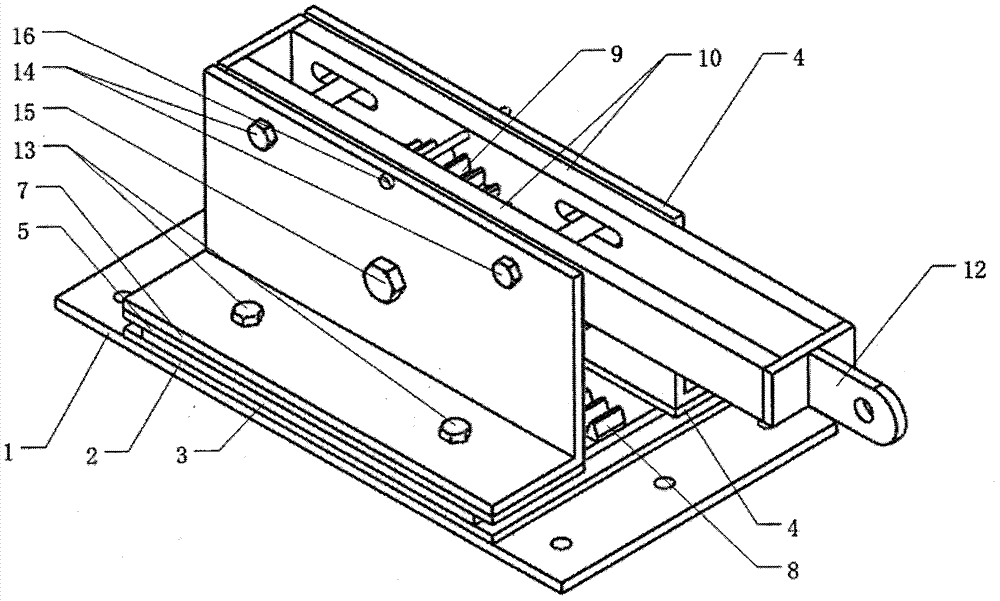

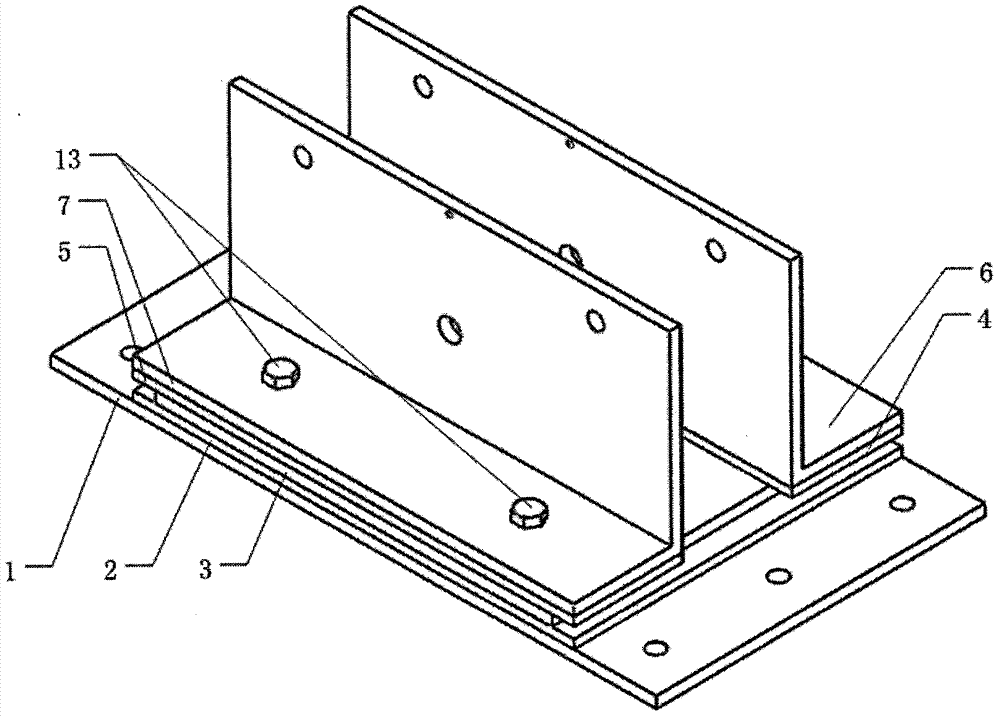

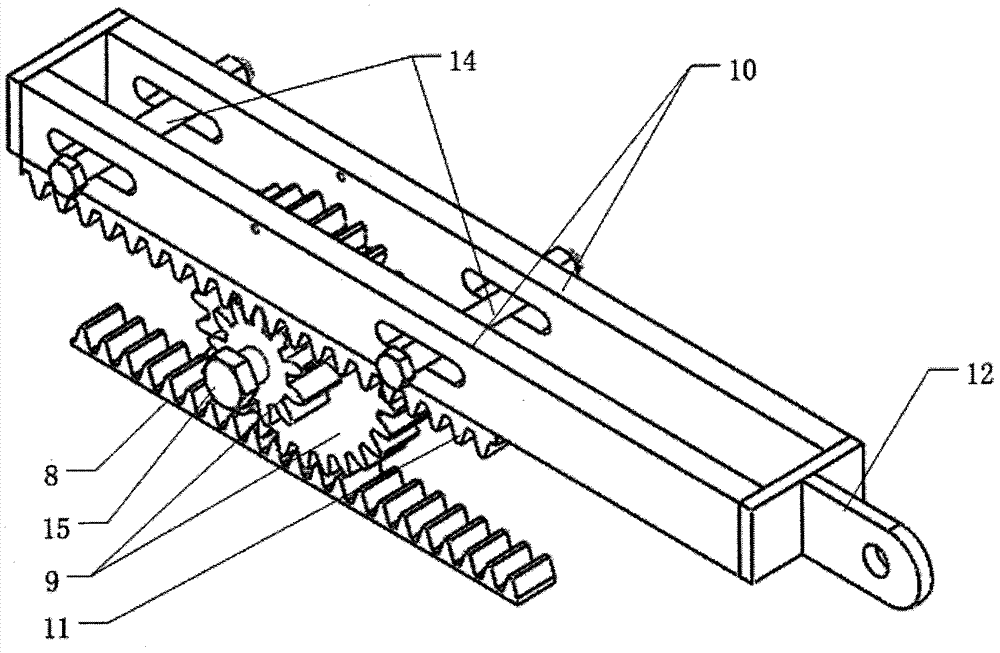

[0029] according to figure 1 with image 3 As shown, the displacement amplified friction damper includes the lower connecting plate 1, the lower friction plate 2, the main board 3, the upper and rear friction plate 4, the upper and front friction plate 5, the rear angle steel 6, the front angle steel 7, the lower rack 8, triple Gear 9, double connecting rod 10, upper rack 11, U-shaped connector 12, high-strength bolt 13, limit bolt 14, gear rotating shaft 15 and positioning pin 16.

[0030] according to figure 2 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 with Figure 10 As shown, two high-strength bolts 13 pass through the rear angle steel bolt hole 903, the upper rear friction plate bolt hole 701, the main board long slot hole 601, the lower friction plate bolt hole 501 and the lower connecting plate bolt hole 401, and the other two hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com