Hydraulic support base

A technology of hydraulic support and bottom plate, which is applied to pillars/supports, mining equipment, earthwork drilling, etc., can solve the problems of large working resistance of hydraulic supports, neglect of coal mining production, waste of coal resources in thin coal seams, etc. The effect of bending and torsion resistance, extending the length of the sidewalk, and being easy to hoist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

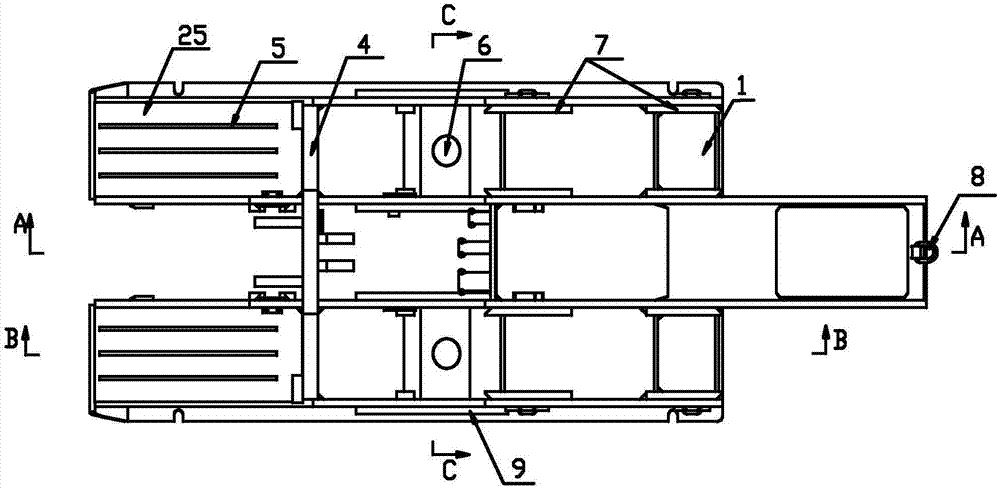

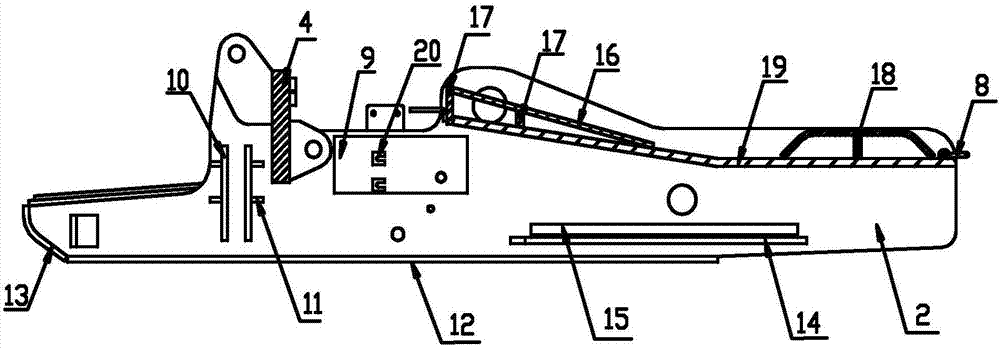

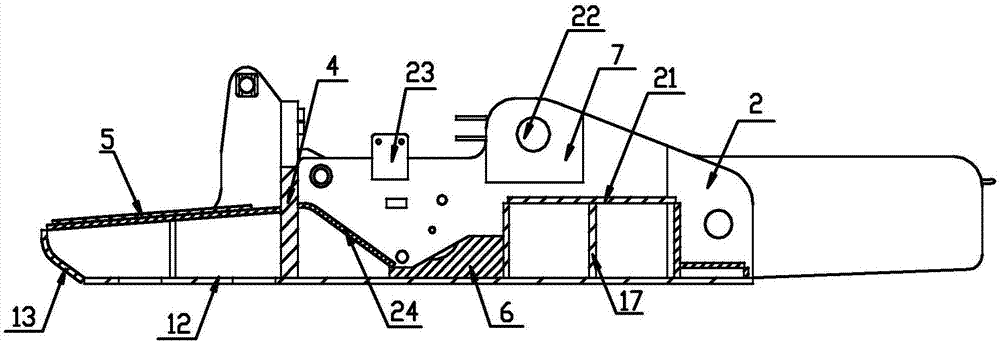

[0030] like Figure 1-6 As shown, a hydraulic support base includes two groove bodies 1 surrounded by main ribs and a bottom plate 12 , and the two groove bodies 1 are connected by bridges 4 . The tank body 1 is provided with a connecting rod connecting hole 22 and a column socket 6, which are respectively used to connect the connecting rod of the hydraulic support and the hydraulic jack. Since the stress is the most concentrated at the connecting rod connecting hole 22, the inner side of the main rib corresponds to the hydraulic jack. A sticker 7 is provided at the connecting hole 22 of the connecting rod for reinforcement. The outer side of the main rib is provided with a reinforcing plate 9 corresponding to the column socket 6, and the reinforcing plate 9 is provided with a hanging block 20 for connecting the oil tank pipeline. The inner side of the main rib is located above the column socket 6 with a valve plate 23. , for connecting the valve.

[0031] The main rib inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com