Sound attenuation structure of vacuum pump and vacuum pump

A vacuum pump and noise reduction technology, which is applied in the direction of pumps, pump components, variable displacement pump components, etc., can solve the problem of high noise of vacuum pumps, and achieve the effect of reducing noise and reducing sound energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

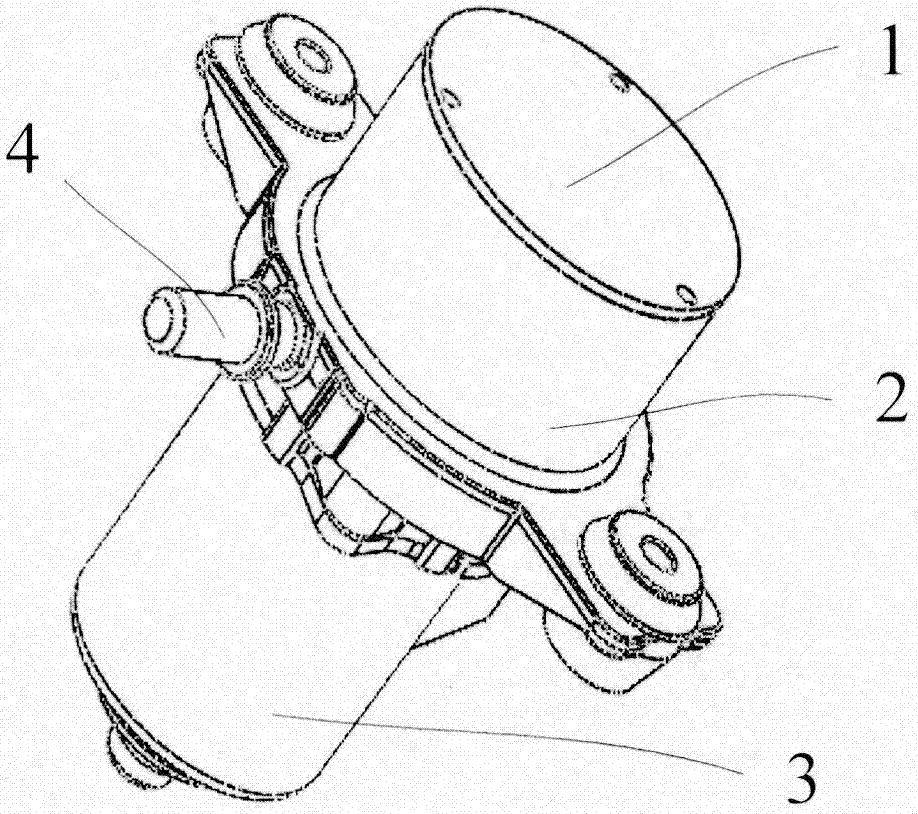

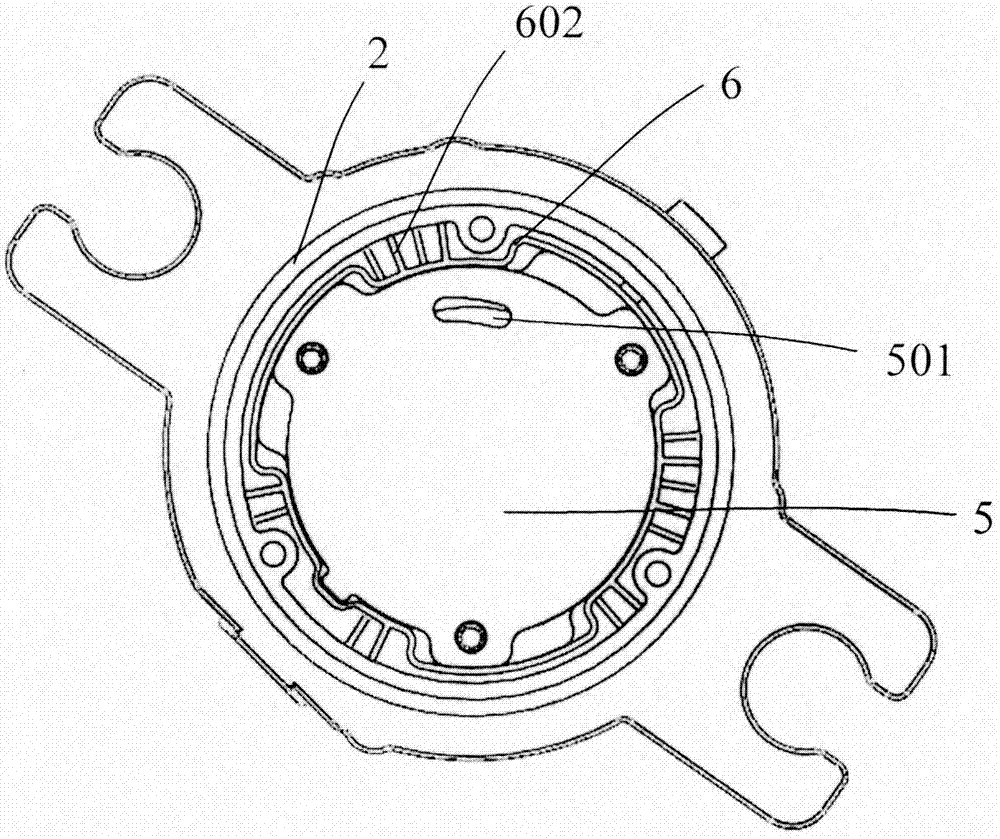

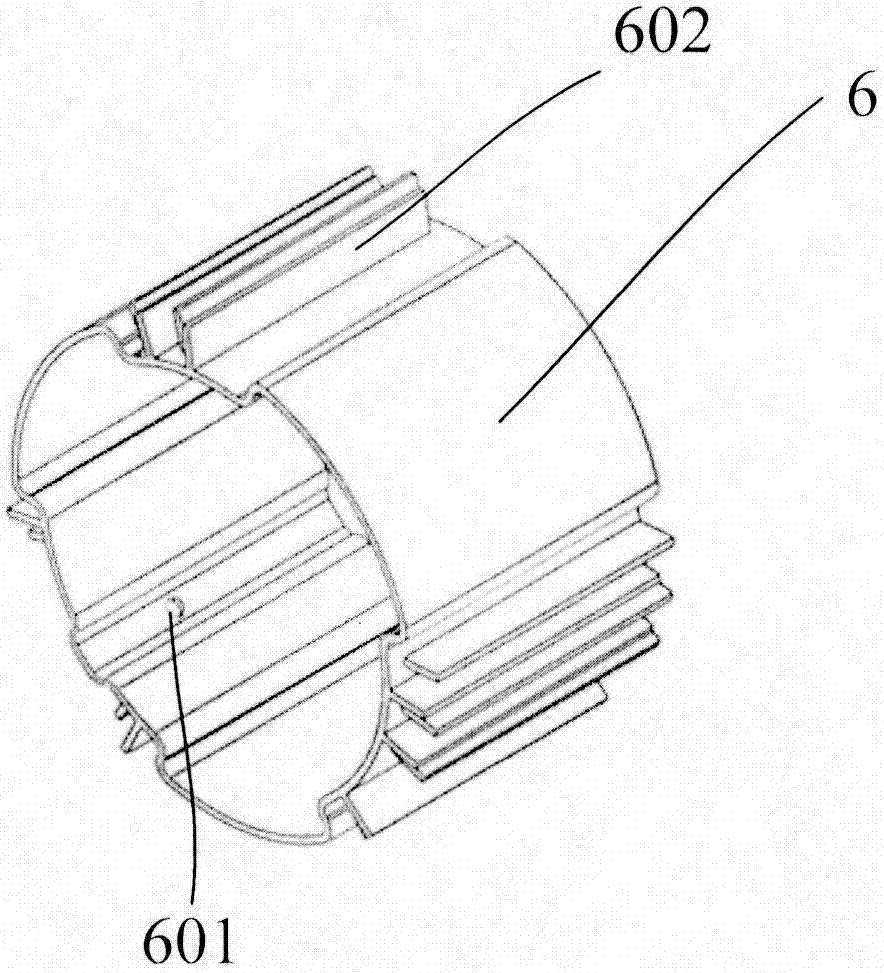

[0027] Hereinafter, preferred embodiments of the noise reduction structure of the vacuum pump and the vacuum pump according to the present invention will be described with reference to the accompanying drawings.

[0028] The vacuum pump involved in the present invention includes a pump assembly and a pump accommodation chamber for accommodating the pump assembly. Wherein, the pump assembly can adopt any suitable structure in the prior art, for example, the structure of the pump cavity of the vacuum pump disclosed in the patent document CN104131979A can be adopted, and other structures can also be adopted, as long as the pumping function can be completed.

[0029] Likewise, the overall structure of the vacuum pump of the present invention can also adopt any suitable structure in the prior art, for example, the overall structure of the vacuum pump disclosed in the patent document CN104131979A can be adopted, that is, it can include a motor, a mounting plate and a noise reduction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com