Variable cross section plate spring assembly

A leaf spring and variable cross-section technology, which is applied to springs, spring components composed of several springs, low internal friction springs, etc., can solve the problems that the comfort of variable cross-section leaf spring products cannot be well solved, and achieve improvement Reliability and riding comfort, eliminating noise in use, and the effect of solving noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

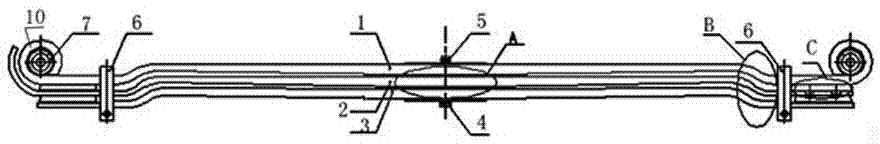

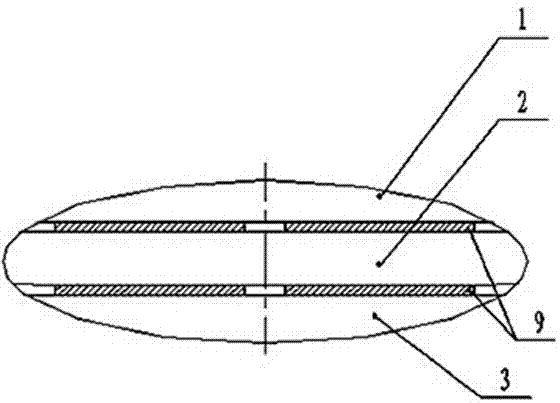

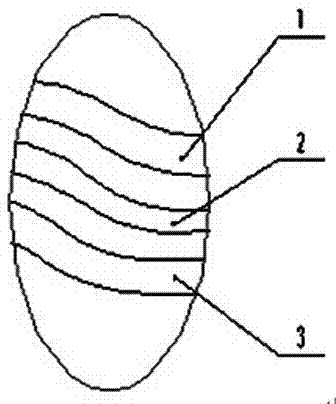

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 shown.

[0022] The present invention is a variable-section leaf spring assembly, including a variable-section leaf spring group. The center of the variable-section leaf spring group is to assemble a plurality of single-piece variable-section leaf springs through prestressing through a central bolt 4 and a nut 5. , the ends of multiple single-piece variable-section leaf springs are subjected to bending treatment, and are fixed together by U-shaped bolts 6 at the ends; the ends of the uppermost variable-section leaf spring 1 are provided with roll lugs 10, and the inside of the roll ears 10 A bushing 7 is provided, and the end of the middle variable-section leaf spring 2 is rolled up into an arc to form an enveloping structure to the roll ear 10, and the end of the bottom variable-section leaf spring 3 is a straight line segment.

[0023] Liners 9 are arranged between each single variable-section leaf spring in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com