Optical position-measuring device

A measuring device and optical technology, applied in the direction of measuring devices, using optical devices, using optical devices to transmit sensing components, etc., can solve problems such as high cost and difficult control, and achieve large output, low cost, and large process window Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

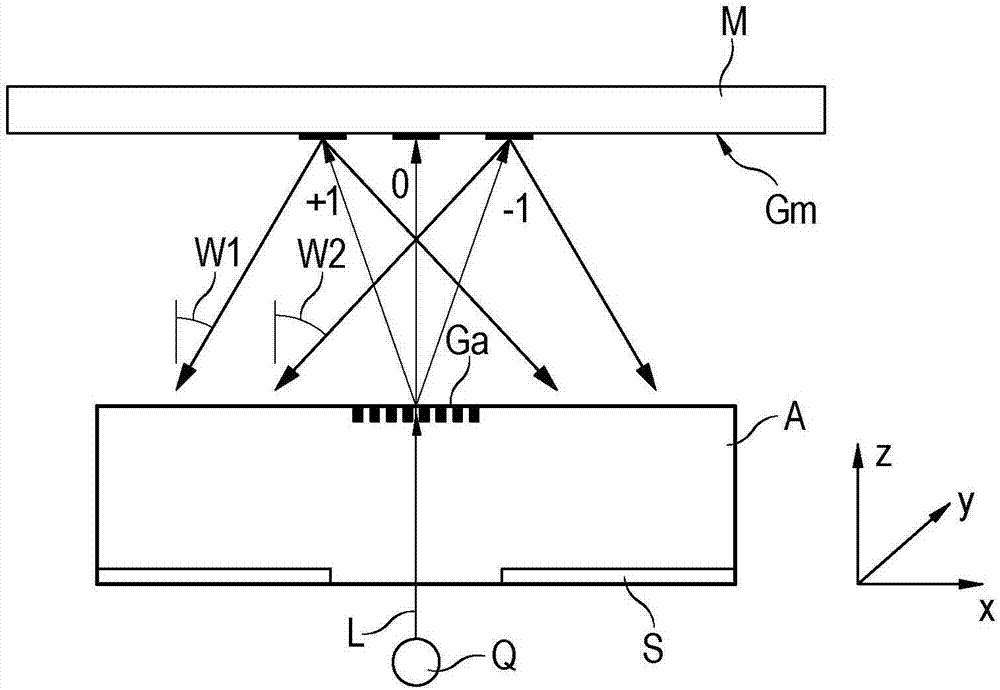

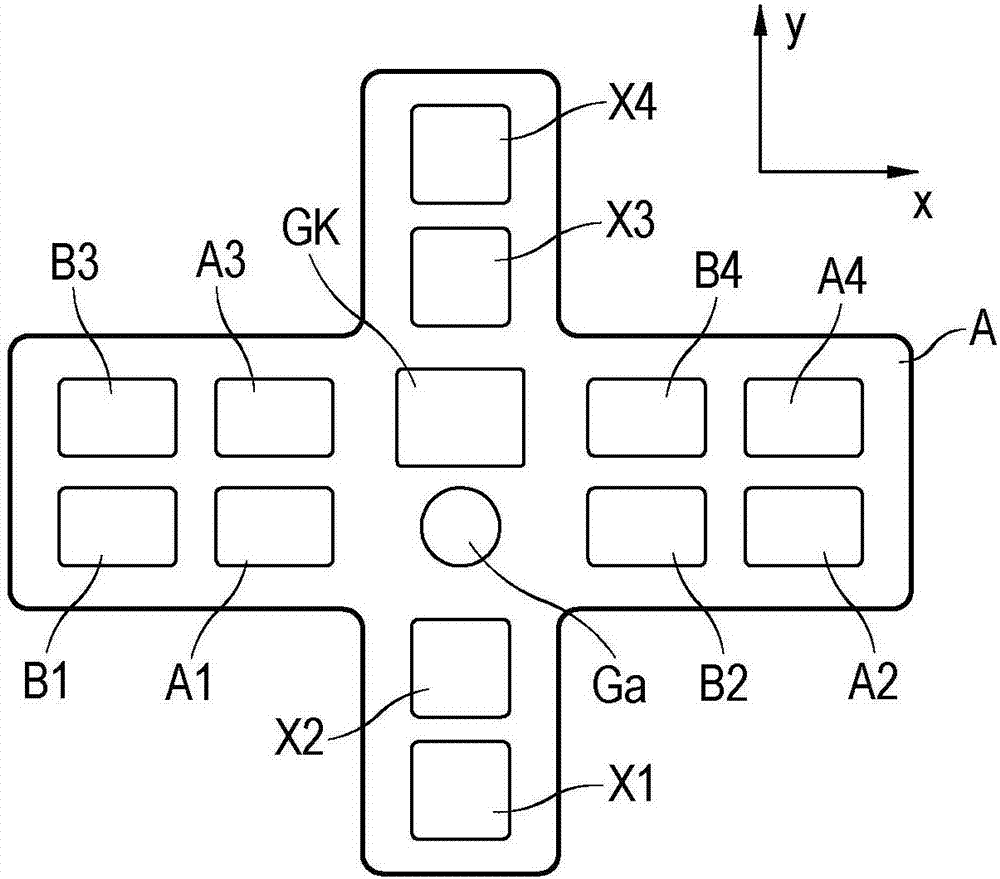

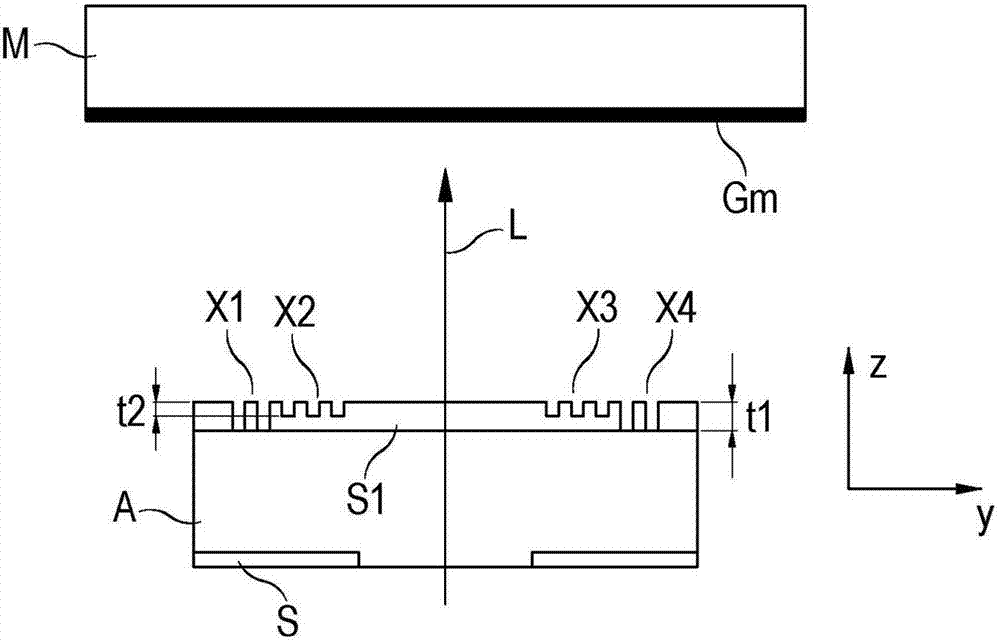

[0017] figure 1 The basic structure of the position-measuring device according to the invention is schematically shown with a planar scanning plate A extending in both directions X and Y and a planar measuring standard M parallel to the scanning plate A. figure 2 A plan view of the side of the scanning plate A facing the measuring standard M is shown.

[0018] The light L of the light source Q passes through the transparent scanning reticle A in the Z direction and impinges on the partition grid Ga, which is arranged on the side of the scanning reticle A facing the measuring standard M. The separation grid Ga separates the light into a plurality of sub-rays +1, 0, -1 of different diffraction orders. The three sub-rays +1, 0, −1 impinge on the optical grid Gm, which is arranged on the side of the measuring standard M facing the scanning plate A. The optical grid Gm is a cross grid, which re-segregates the sub-rays +1, 0, -1 into different diffraction orders, that is, prefera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com