Pressure rod strain type impact force value measurement device and system

A technology for measuring device and impact force, applied in measuring device, force/torque/work meter, measuring rapid changes, etc., can solve the problems of impossibility of impact force measurement, difficulty in experiment, difficult control, etc., to improve test work efficiency , The system structure is reasonable, the effect of fast and reliable measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following embodiments will specifically elaborate on the pressure bar strain type impact force value measuring device and the pressure bar strain type impact force value measurement system of the present invention in conjunction with the accompanying drawings .

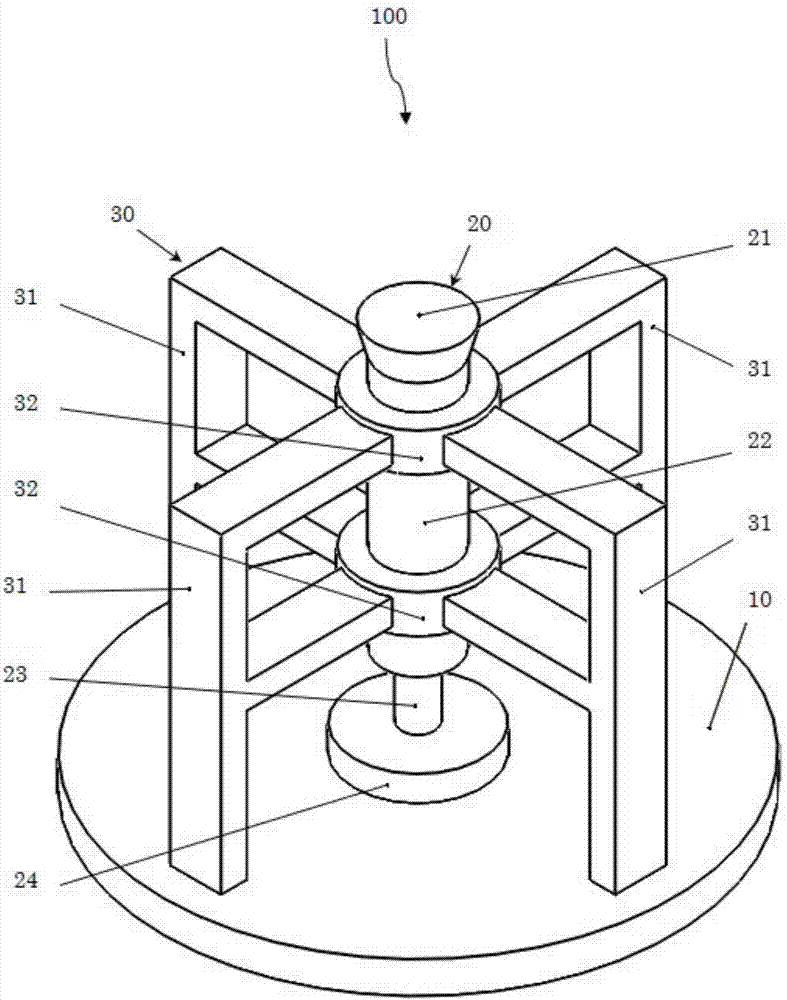

[0015] figure 1 It is a structural schematic diagram of the pressure rod strain type impact force value measuring device in the embodiment of the present invention.

[0016] Such as figure 1 As shown, the measuring device 100 of the compression bar strain type impact force value includes: a base 10 , a measuring part 20 and a fixing part 30 .

[0017] In this embodiment, the base 10 is configured as a cylinder, but it is not limited thereto. In actual situations, the base 10 can also be a prism, a circular platform, and the like.

[0018] The measurement unit 20 is disposed abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com