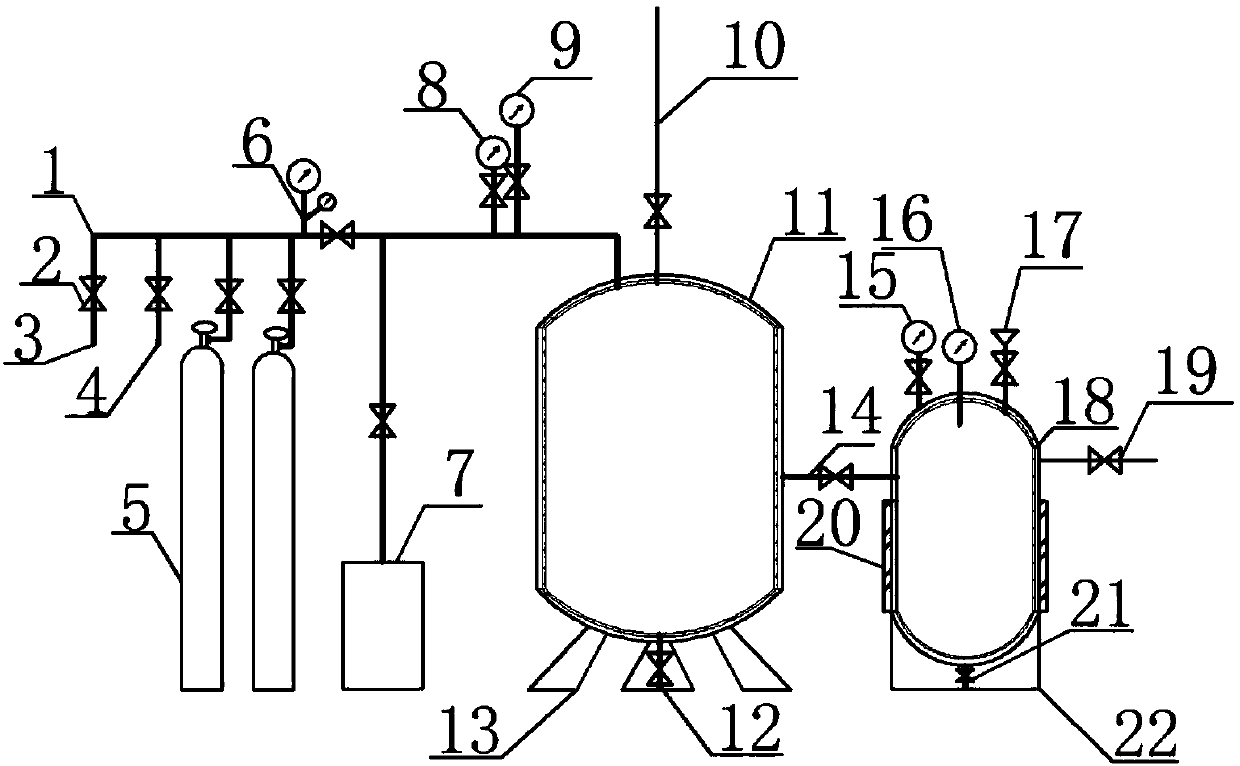

Gas mixing device for burning and explosion tests of combustible gas, liquid steam and dust

A liquid and steam technology, which is used in gas and gas/vapor mixing, transportation and packaging, mixer accessories, etc. It can solve the problems of low experimental efficiency, inability to heat the gas mixing tank, and inability to heat the gas, and achieve a reasonable system structure and reduce Experimentation expenses, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A gas distribution method of a combustible gas gas distribution device (taking air-hydrogen premixing as an example) The method includes the following steps:

[0016] (1) Calculate the required partial pressure of hydrogen gas according to the partial pressure method. The gas mixing tank is 30L, the required total gas pressure is 2MPa, and the required hydrogen concentration is 10%, then the partial pressure of the hydrogen gas is calculated as 0.2MPa by the partial pressure method.

[0017] (2) Open the cut-off valve on the vacuum gauge and vacuum pump, close other valves, start the vacuum pump to evacuate the gas mixing tank, observe the reading of the vacuum pressure gauge, when the reading reaches -0.1MPa, close the cut-off valve on the vacuum pump and the vacuum gauge, and open Hydrogen gas inlet valve, let 0.2MPa hydrogen gas into the air inlet, then close the hydrogen gas inlet valve, then open the compressed air inlet valve, let in air, when the pressure gauge r...

Embodiment 2

[0020] A gas distribution method for combustible gas and liquid steam (air-methane-ether as an example)

[0021] (1) The gas mixing tank is 30L, and the total gas pressure required for the heating tank volume of 15L is 1MPa, the required methane concentration is 20%, and the ether concentration is 10%. Pressure 0.1MPa, according to the pressure, temperature and volume to calculate the required quality of liquid ether. The actual pressure of the heating tank is 0.3MPa.

[0022] (2) Open the liquid inlet valve of the heating tank, add ether, close the inlet valve, open the stop valve on the vacuum gauge and the vacuum pump, close other valves, start the vacuum pump to vacuum the gas mixing tank and the heating tank, and observe the reading of the vacuum pressure gauge, When the reading reaches -0.1MPa, close the valves on the vacuum pump and vacuum gauge, close the valve between the gas mixing tank and the heating tank, open the methane gas inlet valve, let 0.2MPa methane gas i...

Embodiment 3

[0025] A method for gas distribution of liquid vapor (gasoline as an example)

[0026] (1) The gas mixing tank is 30L, and the total gas pressure required for the heating tank with a volume of 15L is 0.8MPa.

[0027] (2) Open the liquid inlet valve of the heating tank at the same time, add gasoline, close the inlet valve, open the stop valve on the vacuum gauge and the vacuum pump, open the stop valve between the gas mixing tank and the heating tank, close other valves, start the vacuum pump to the gas mixing pipe Carry out vacuuming, observe the reading of the vacuum pressure gauge, when the reading reaches -0.1MPa, close the valve on the vacuum pump and the vacuum gauge, turn on the heating belt, set the heating temperature for heating, and when the reading of the pressure gauge reaches 0.8MPa. Turn off heat.

[0028] (3) After the test, open the vent valve and gas inlet valve, pass in compressed air to purge the residual gas in the system, and open the stop valve on the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com