Structure identification method of vulcanized joints of steel wire rope core conveyer belt of coal mine

A technology of steel wire rope core and joint structure, applied in the direction of the size/direction of the magnetic field, can solve the problems of coal mine production and safety hazards, steel wire rope core conveyor belt breakage, coal mine economic loss and other problems, to improve efficiency, reduce sampling points, and identify accurate reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

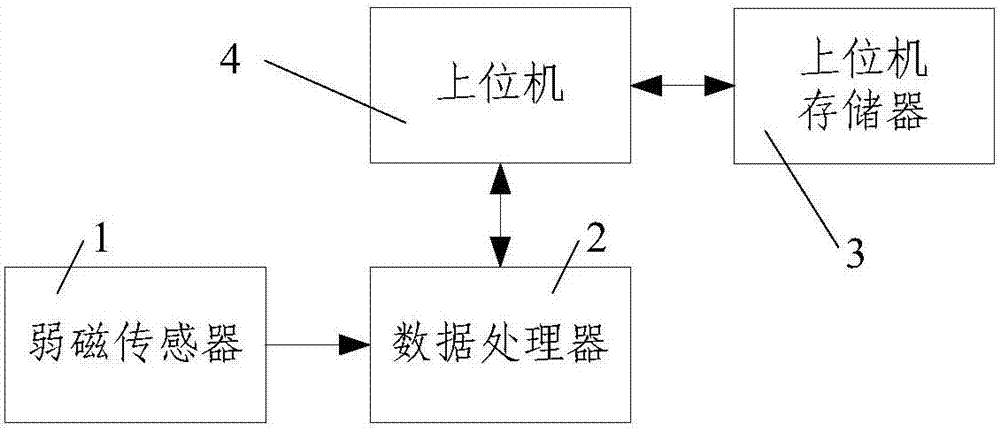

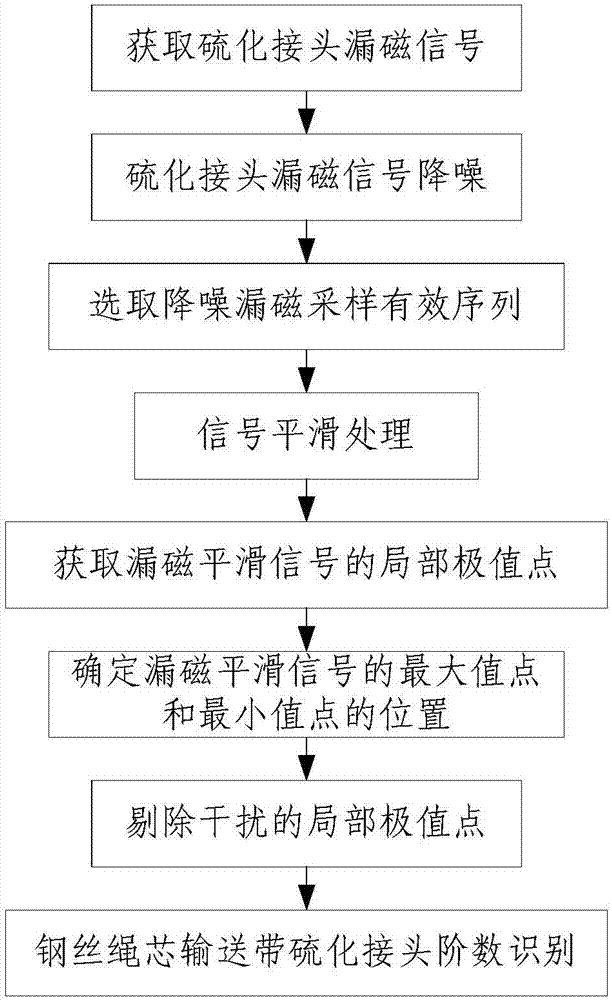

[0041] Such as figure 1 and figure 2 As shown, a method for identifying the vulcanized joint structure of a coal mine steel cord conveyor belt of the present invention comprises the following steps:

[0042] Step 1. Obtain the magnetic flux leakage signal of the vulcanized joint: first, use a weak magnetic loading device to magnetically load the vulcanized joint of the identified steel cord conveyor belt; magnetic signal, and synchronously input the collected vulcanized joint magnetic flux leakage signal to the data processor 2, and store it in the host computer memory 3;

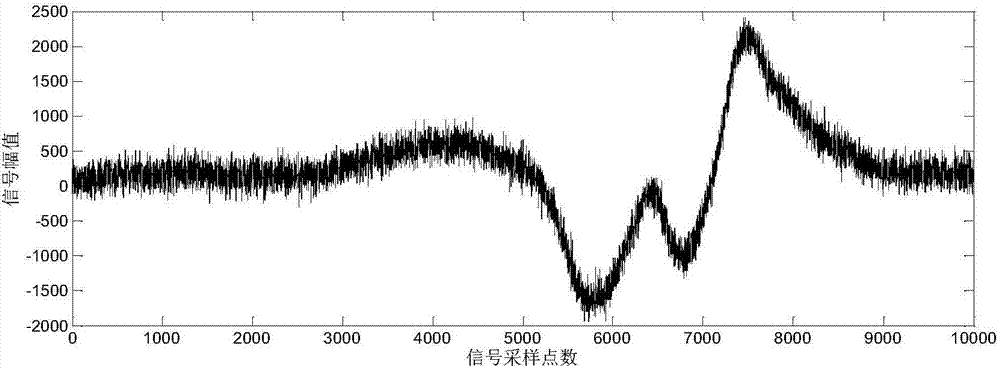

[0043] The magnetic flux leakage signal of the vulcanized joint perpendicular to the plane of the steel cord conveyor belt collected by the magnetic field weakening sensor 1 is the original magnetic flux leakage sampling sequence X(k), where k=1, 2, 3...n, n is the original magnetic flux leakage sampling sequence The number of sampling points in X(k);

[0044] In this embodiment, the number of sampling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com