Camera and anti-shake method of the camera

A camera and lens assembly technology, applied in the field of photography, can solve the problems of complex design, large structure and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

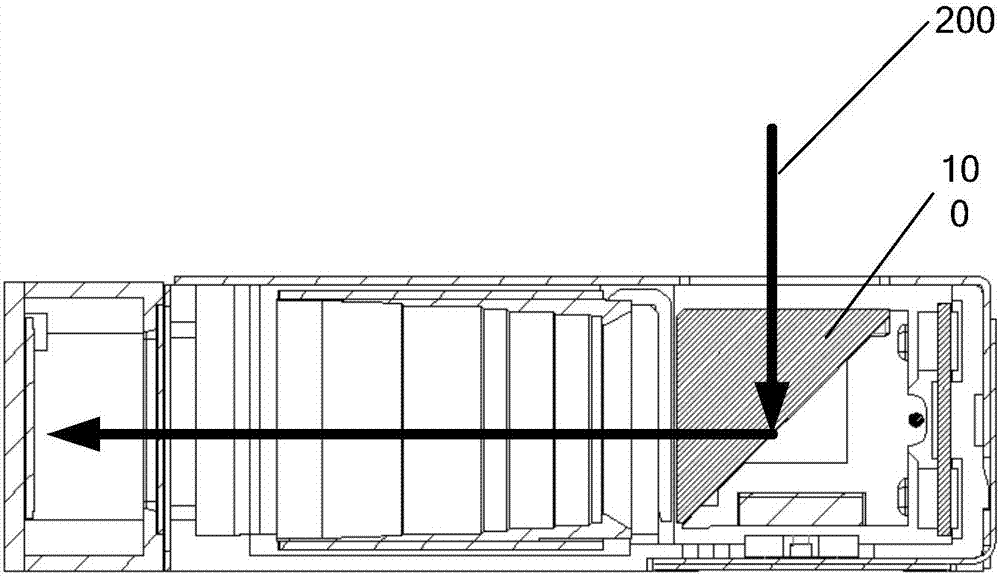

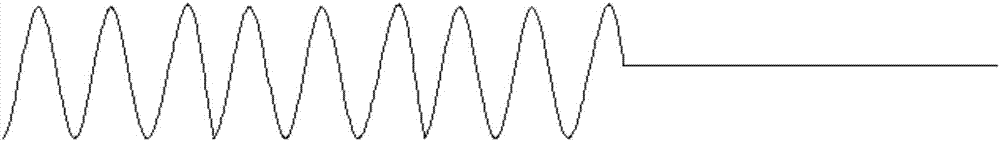

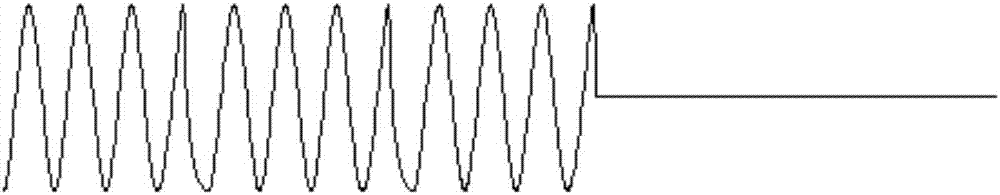

[0027] see Figure 4 , the present embodiment provides a camera, including a total reflection mirror assembly 10, a lens assembly 20 and a circuit assembly 30; the total reflection mirror assembly 10 includes a total reflection mirror 11 and a first shape memory alloy metal disposed on the total reflection mirror 11 Wire 12, the lens assembly 20 includes a lens, and the circuit assembly 30 includes a tilt detector 31 and a drive chip 32; wherein the tilt detector 31 is used to detect the shaking parameters of the total reflection mirror 11 shaking, and convert the shaking parameters into a first electrical signal To transmit; the drive chip 32 is used to receive the first electrical signal, calculate the compensation displacement according to the first electrical signal, and output the first current to the first shape memory alloy wire 12 after calculation; the first shape memory alloy wire 12 is used to generate the first pulling force under the action of the first current to...

Embodiment 2

[0059] see Figure 12 , this embodiment provides a camera anti-shake method, the anti-shake method is suitable for the camera in the first embodiment, the anti-shake method includes:

[0060] Step S1: Detect the shaking parameters of the shaking of the total reflection mirror 11, and convert the shaking parameters into a first electrical signal for transmission.

[0061] Step S2: receiving the first electrical signal, calculating the compensation displacement according to the first electrical signal, obtaining a first current according to the compensation displacement, and outputting the first current to the first shape memory alloy wire.

[0062] Step S3: the first shape memory alloy wire 12 generates a first pulling force under the action of the first current, and pulls the total reflection mirror 11 to perform a position compensation movement.

[0063] When the total reflection mirror 11 shakes, the lens shifts accordingly, so as to reduce the impact caused by the shake. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com