Annealing sealing device

A sealing device and annealing technology, used in heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve the problems of gas leakage in the annealing furnace, low surface temperature, reduced mechanical properties of the workpiece surface, etc., to ensure quality, safety, and good sealing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

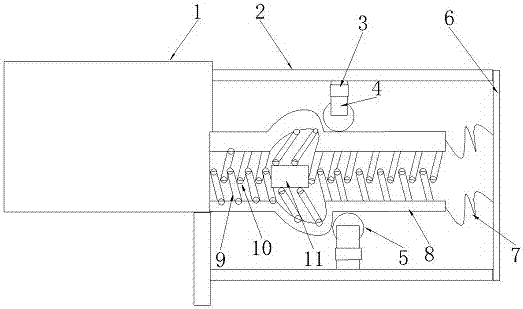

[0015] The reference numerals in the accompanying drawings include: annealing furnace 1, support 2, telescopic rod 3, pole 4, roller 5, connecting rod 6, spring 7, sealing sleeve 8, sealing sheet 9, rolling ball 10, workpiece 11.

[0016] The embodiment is basically as figure 1 Shown:

[0017] The annealing sealing device of the present embodiment comprises an annealing furnace 1, and two supports 2 perpendicular to the entrance of the annealing furnace 1 are symmetrically welded on the side wall of the entrance of the annealing furnace 1, and the ends of the two supports 2 are provided with connecting plates, The two brackets 2 are provided with chute, the chute of the two brackets 2 is slidably connected with the strut 4, and the telescopic rod 3 is nested with each other along the length direction of the strut 4. The end of the pole 4 is rotatably connected with a ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com