Inertia type fluid transportation and pressurization method and device

An inertial, fluid output port technology, applied in the direction of machines/engines, mechanical equipment, pumps, etc., can solve the problem of large power consumption, achieve low power consumption and improve energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

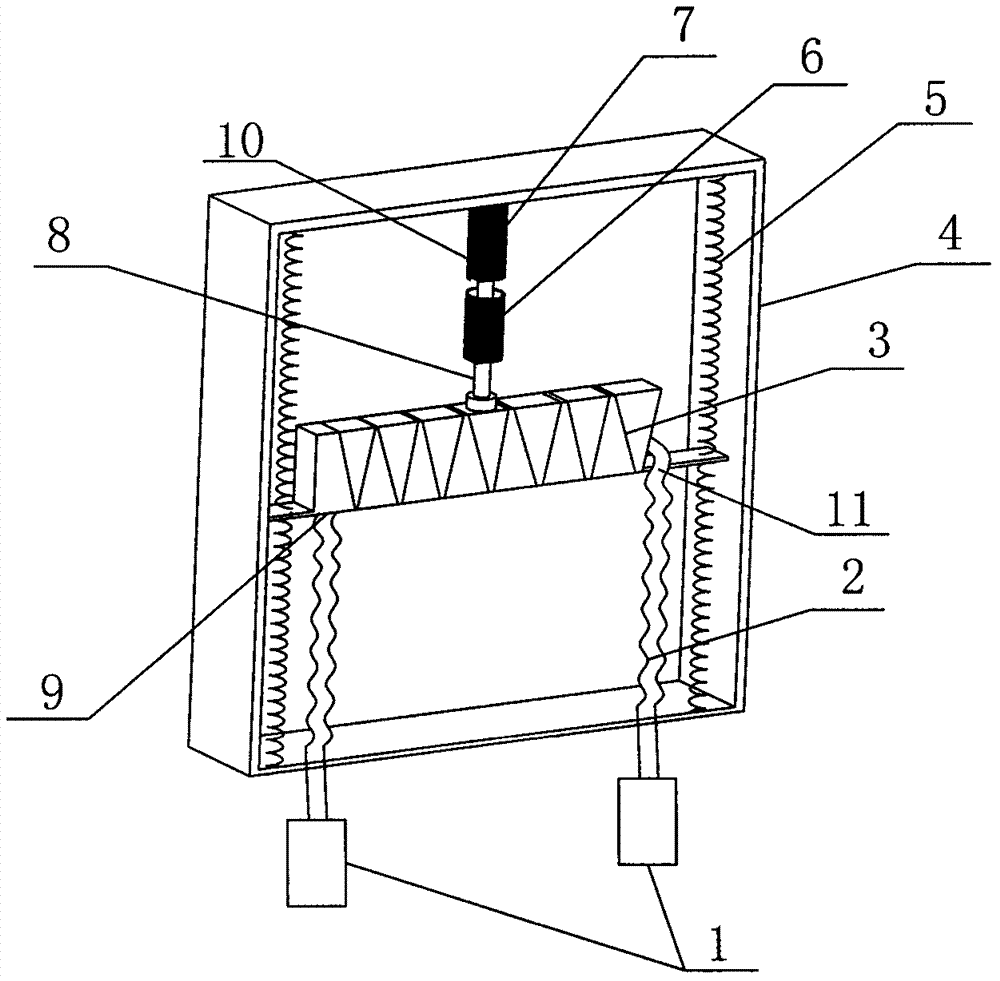

[0019] The present invention uses a plurality of containers 3 to be sequentially connected in series, and each container 3 contains fluid, especially gas, and two through holes spaced apart from each other are arranged on the container 3 as a fluid input port and a fluid output port, and the fluid input port and the fluid output port The fluid outlets are all equipped with one-way valves to control the one-way input and output flow of the fluid. The fluid input port on the latter container 3 communicates with the fluid output port on the previous container 3, and the vibration drive mechanism is used to drive the container 3 to vibrate to make the container 3. The movement direction of the fluid in the inner cavity changes alternately. Through the extrusion of the fluid under the action of inertia and the one-way control of the flow direction of the fluid by the one-way valve, the fluid in the container flows through each container in turn during the vibration of the container. ...

Embodiment approach 2

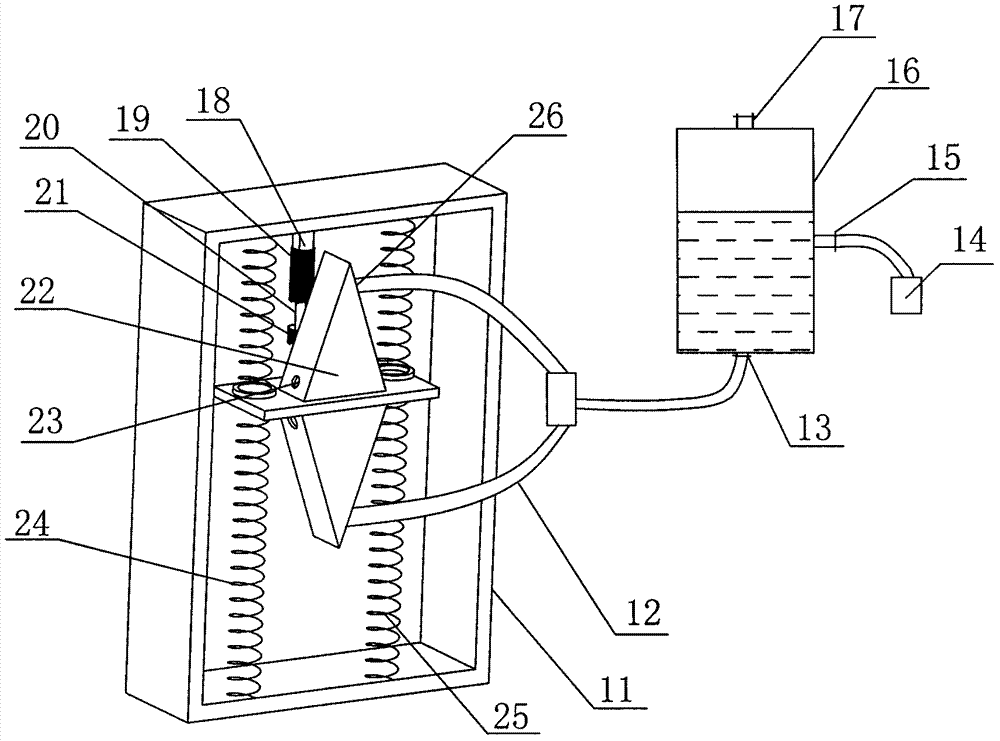

[0022] The present invention uses a plurality of mutually independent containers 22 to be fixedly connected in parallel, and each container 22 contains fluid, especially liquid, and two through holes at a distance are set on the container 22 as the fluid input port 23 and the fluid output port 26 , the fluid input port 23 and the fluid output port 26 are all provided with one-way valves to control the one-way input and output flow of the fluid, and the vibration drive mechanism is used to drive the container to vibrate back and forth, and each container 22 is arranged side by side on the vibration direction, and each container 22 The fluid output ports 26 on the top are connected to each other through pipelines, and are output from the fluid output ports 26 of each container and then converged and output through the connected pipelines. During the vibration process of the container, the fluid movement direction in the container changes alternately, and the fluid is generated und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com