Aerosol generation system including removable cartridge

A technology of aerosol generation and air flow, which can be used in drug devices, nebulizers for treatment, other medical devices, etc., and can solve problems such as liquid residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

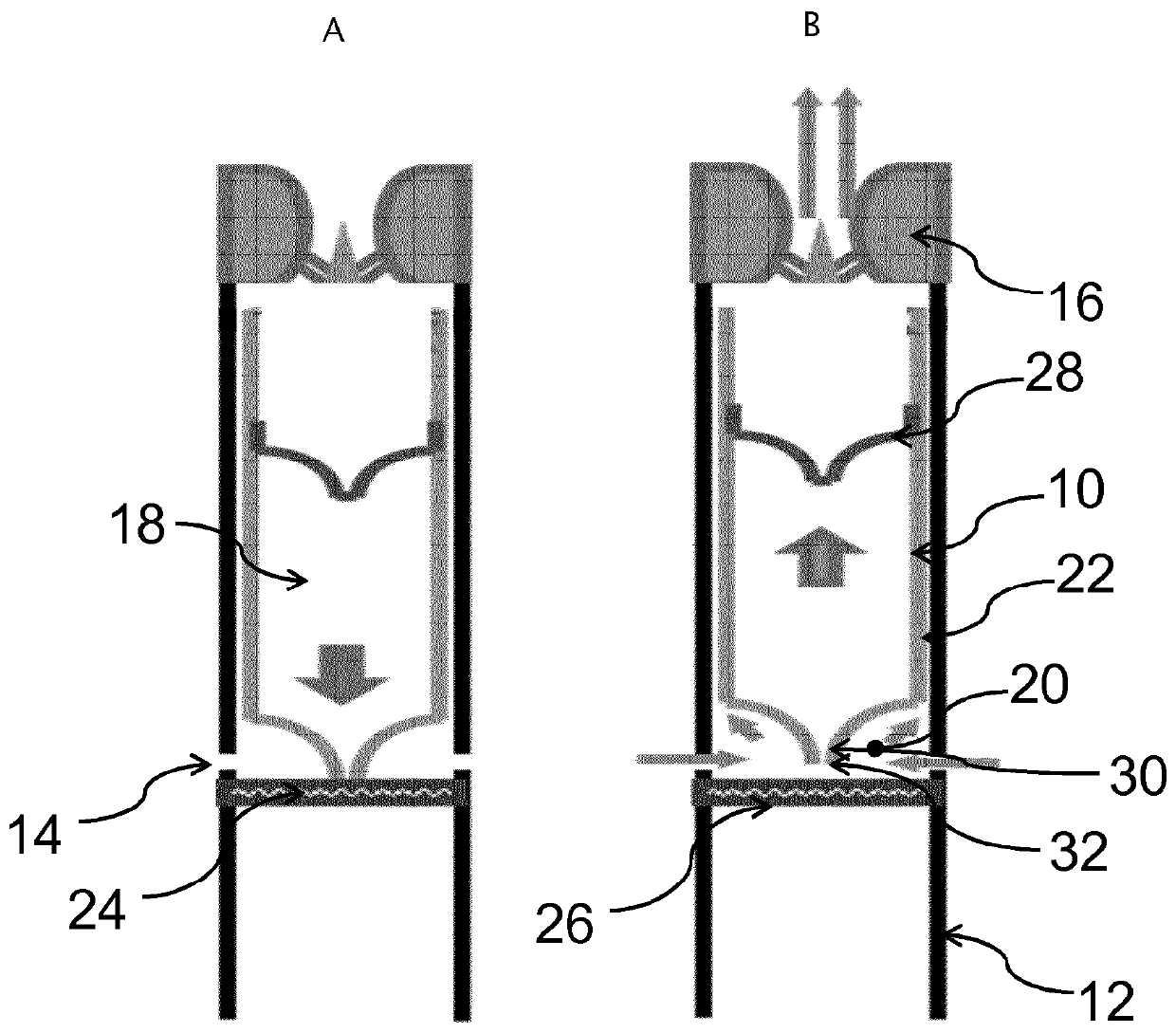

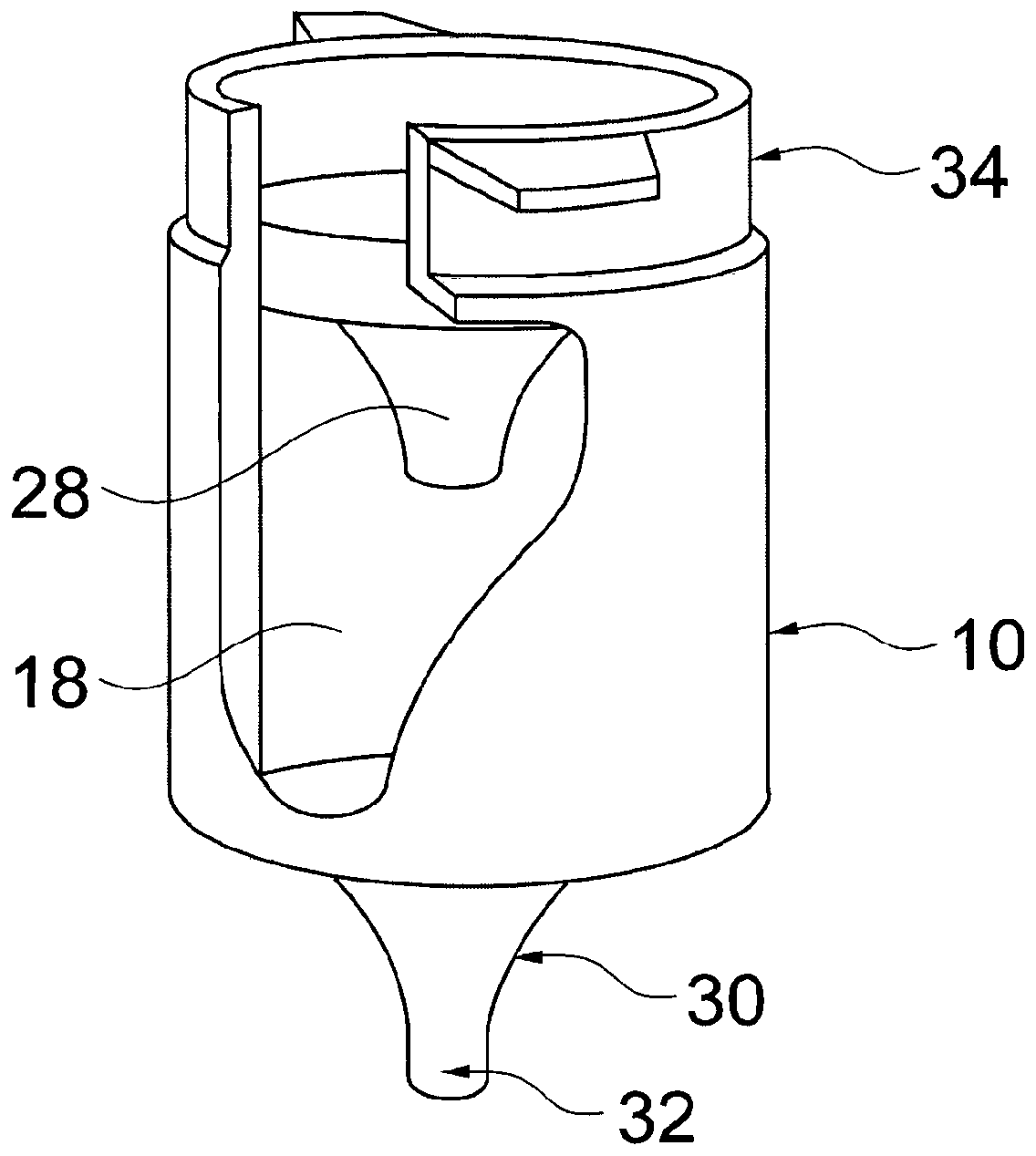

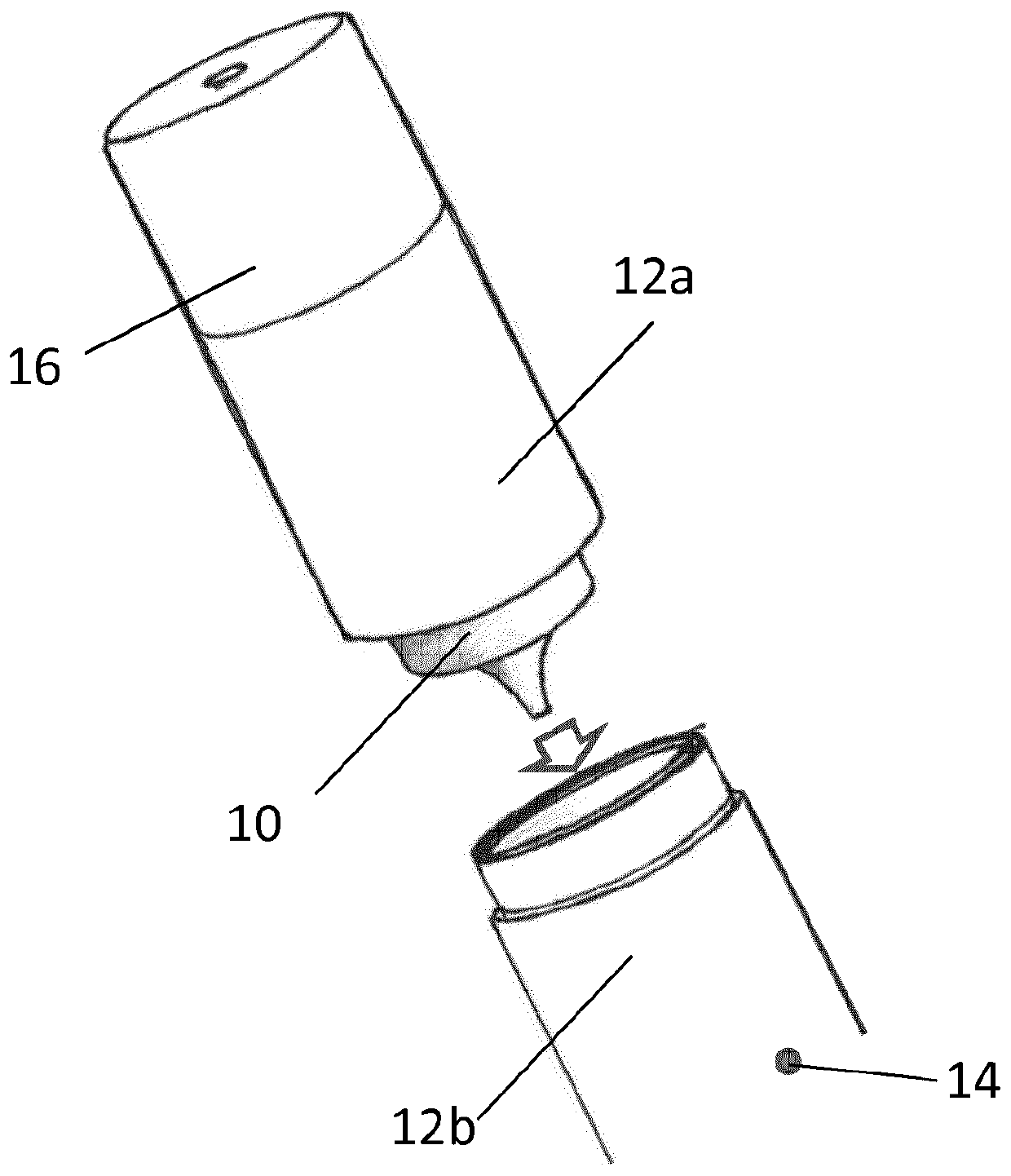

[0057] figure 1 A and figure 1 B shows a schematic diagram of an aerosol generating system incorporating a movable cartridge 10 containing an aerosol generating liquid. exist figure 1 A and figure 1 In B, the aerosol generating system is an electronic cigarette comprising a housing 12 with an air inlet 14 and a mouthpiece 16 representing the air outlet. An airflow path is defined between the air inlet 14 and the mouthpiece 16 . The airflow path directs airflow from the air inlet 14 , through the aerosol-forming chamber 20 , through the circular gap 22 between the barrel 10 and the inner surface of the housing 12 to the mouthpiece 16 . A heater element 24 is disposed at a distal wall 26 of the aerosol-forming chamber. The cartridge 10 includes a movably mounted piston 28 and a nozzle 30 having a discharge end 32 for dispensing liquid from a liquid storage portion 18 inside the cartridge 10 onto the heater element 24 . The liquid storage portion 18 corresponds to the volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com