Method, filter module and air cleaning device

A filter and air technology, applied in chemical instruments and methods, external electrostatic separators, magnetic separation, etc., can solve problems such as noise in operation, impossibility to pass through, and high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

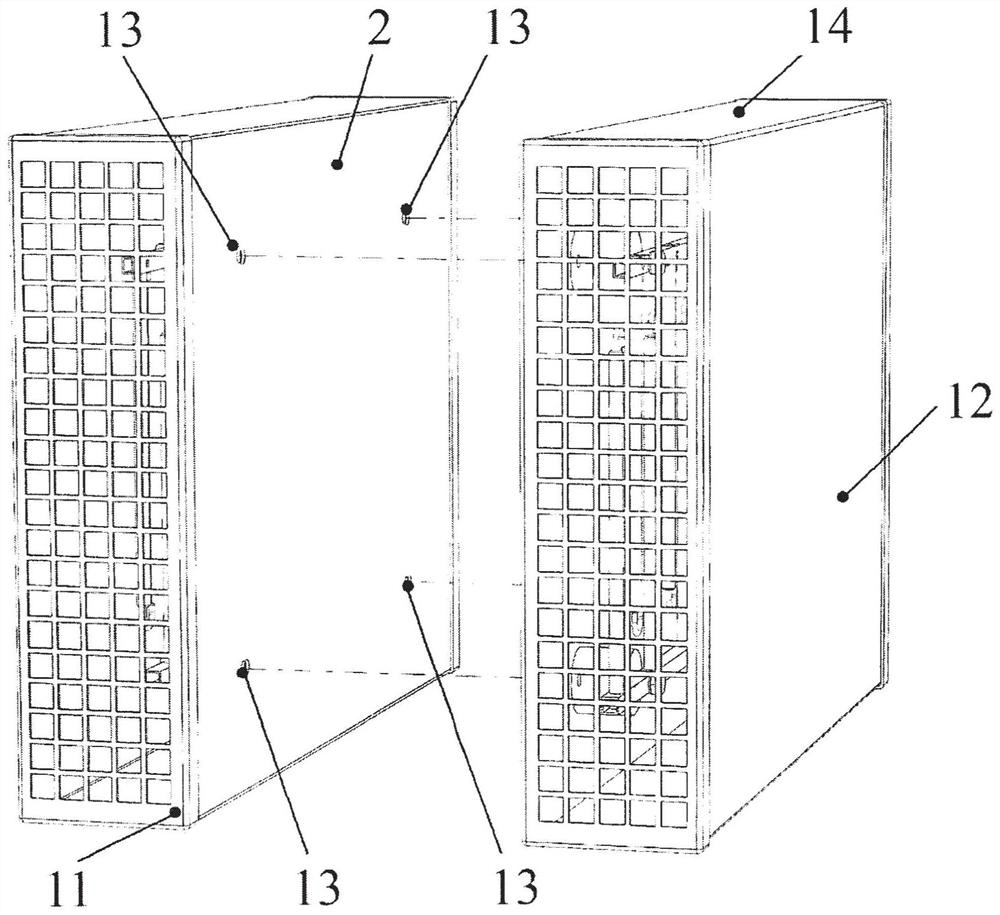

[0026] For the purposes of the present invention, mirror mounting means that the filter module 1 is mounted on the opposite side (back) of the base plate 2, rotated by 180 degrees, and equipped with a housing rotation part 19 .

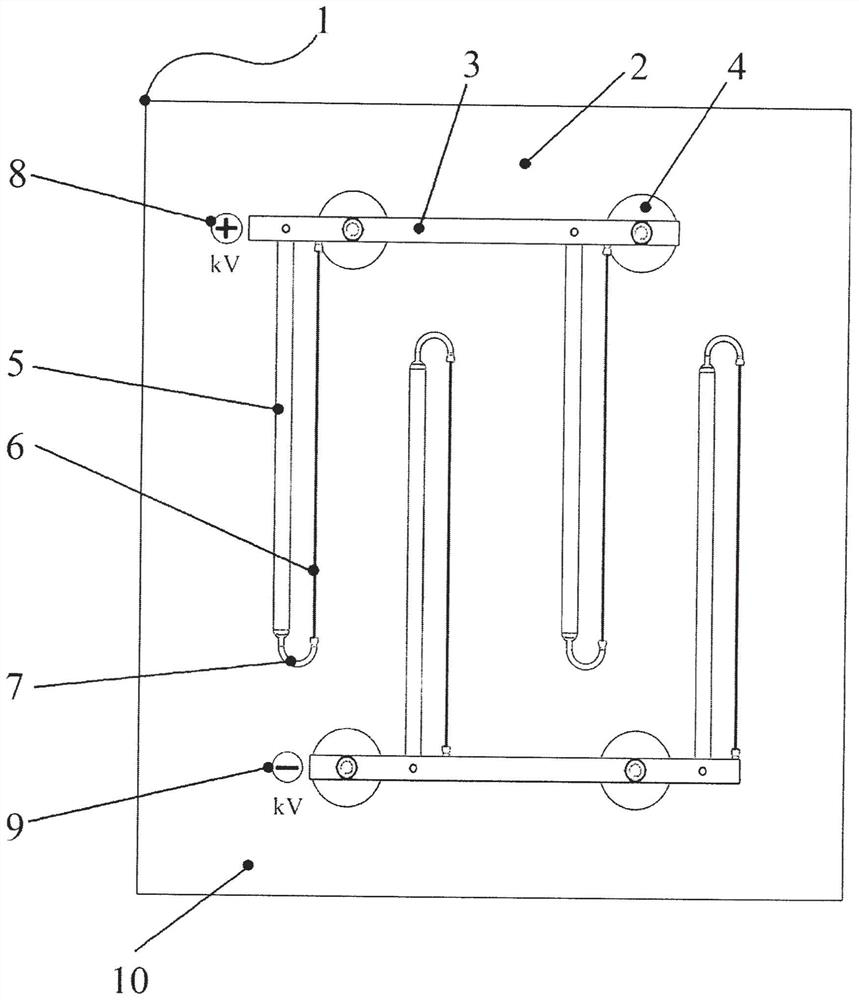

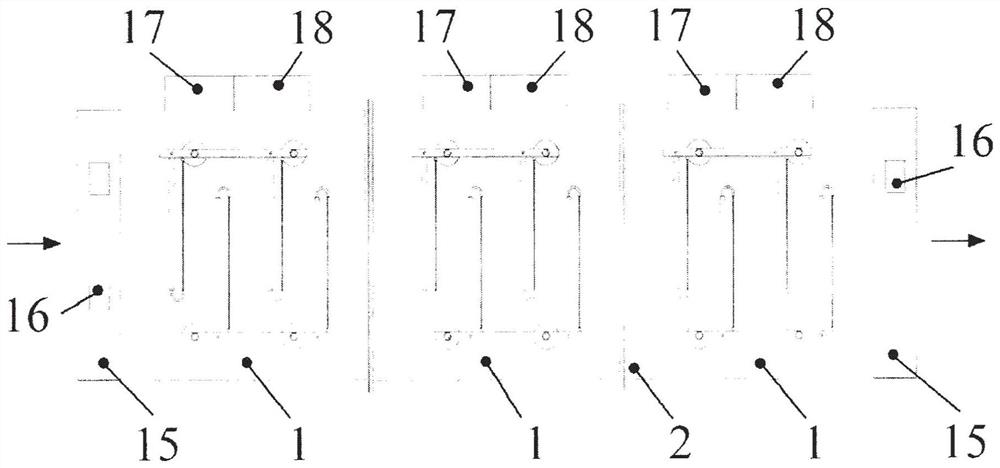

[0027] figure 1 A front view of an advantageous realization of a filter module 1 according to the invention is shown. The filter module 1 is mounted on a base plate 2 which is connected to zero potential 10 like the side plates and cover plates not shown in this figure. The figure also shows two electrode tracks 3 which have four insulating blocks 4 and are connected to a positive high voltage 8 or a negative high voltage 9 . Positive high voltage 8 and negative high voltage 9 by image 3 The power supply unit 17 shown produces. Four electrodes 7 , each comprising a collector 5 and a separator 6 , are connected to these two electrode tracks 3 . An electrode pair has two opposite electrodes 7 connected respectively to positive high voltage 8 and ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com