Manufacturing method of steel pipe and stamping die used in the method

A manufacturing method and stamping die technology, applied to the manufacture of steel pipes and the field of stamping dies used therein, capable of solving problems such as deterioration of roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

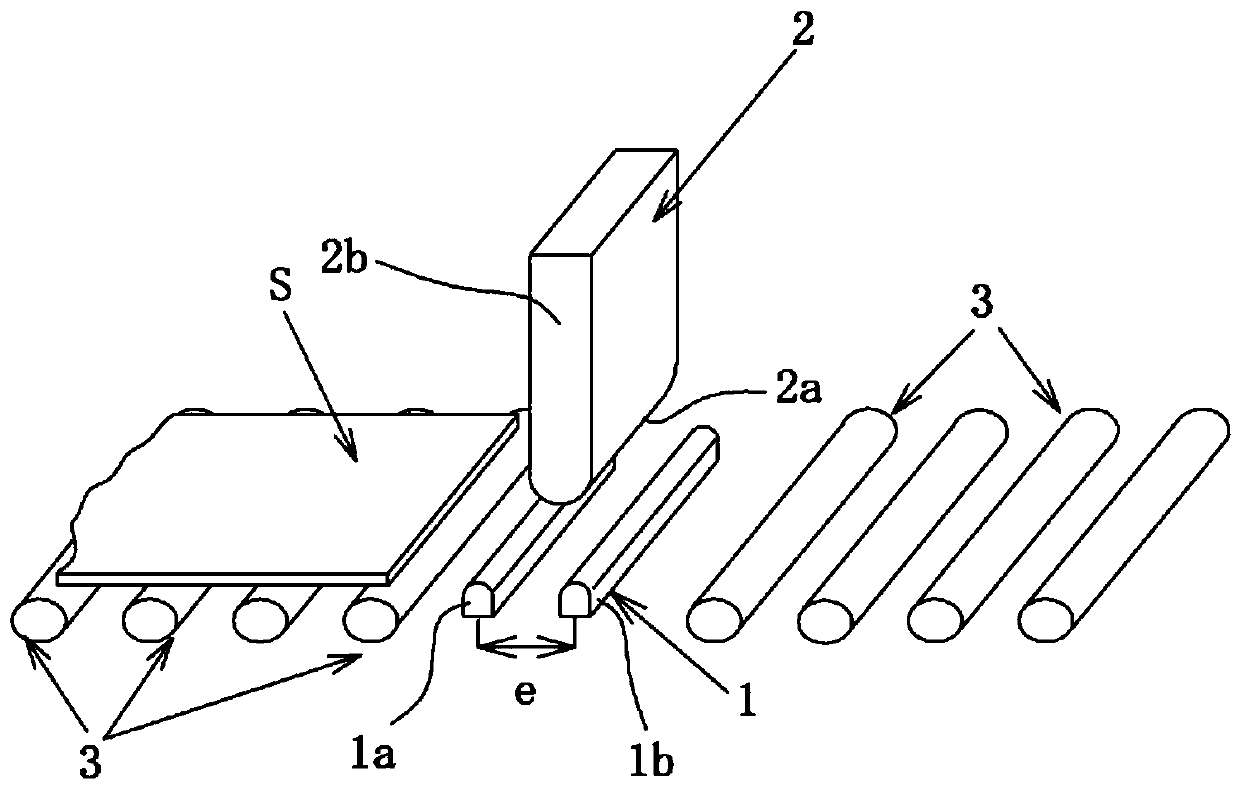

Method used

Image

Examples

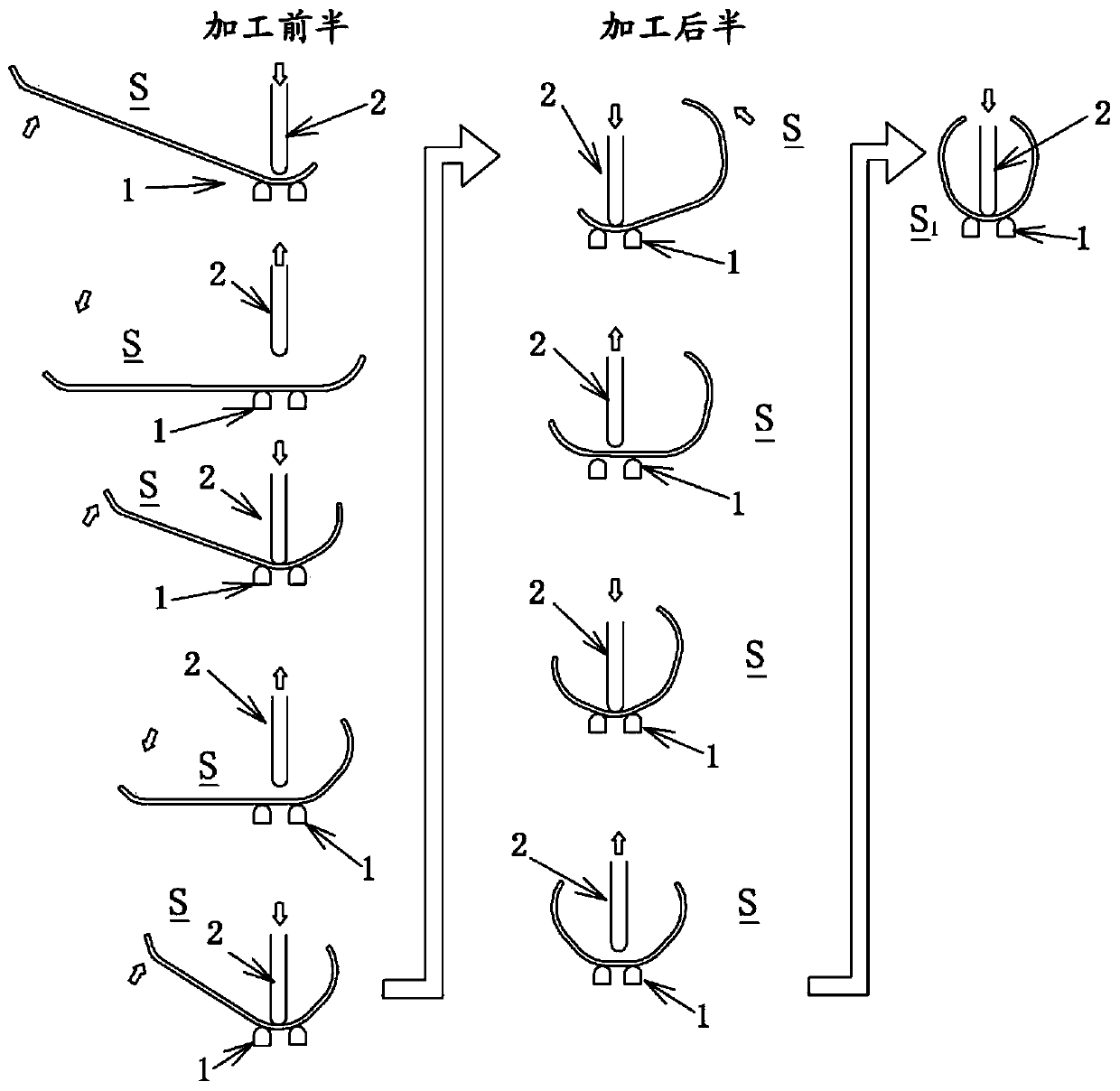

Embodiment 1

[0110] In order to form a steel pipe with a diameter of 36 inches using a steel plate for linepipes (API grade X60) with a thickness of 38.1mm and a width of 2711mm, it is placed on a die with a distance of 450mm between rod-shaped parts, and a steel pipe with a radius of 308mm processing surface punch, from the position 1120mm away from the width center of the sheet, make the sheet feeding pitch 224mm, press 11 times (5 times from the right end of the paper, 5 times from the left end) to perform 3-point bending bending processing. At this time, the amount of pressing is such that the front end of the punch reaches a position of 15.8 mm from the line connecting the uppermost parts of the rod-shaped member, and bends 30° at a time, but at a position 672 mm from the center of the width of the plate (the third from the right end) times, the third feed from the left end) No pressing is performed, and an unprocessed part is formed at a position of 571 to 795 mm. Next, the molded b...

Embodiment 2

[0114] As in Example 1, in order to form a steel pipe with a diameter of 36 inches using a steel plate for linepipes (API grade X60) with a thickness of 38.1 mm and a width of 2711 mm, it is placed on a die whose interval between rod-shaped members is set to 450 mm Above, using a punch with a processing surface with a radius of 308mm, from a position 1120mm away from the center of the width of the sheet, make the feeding interval of the sheet 224mm, and the number of pressings is 11 times (5 times from the right end of the paper, and 5 times from the left end) 5 times) to perform a bending process of 30° once based on 3-point bending. At this time, the amount of pressing is such that the front end of the punch reaches a position of 15.8 mm from the line connecting the uppermost parts of the rod-shaped member, and bends 30° at a time, but at a position 672 mm from the center of the width of the plate (the third from the right end) time, the third feed from the left end), reduce...

Embodiment 3

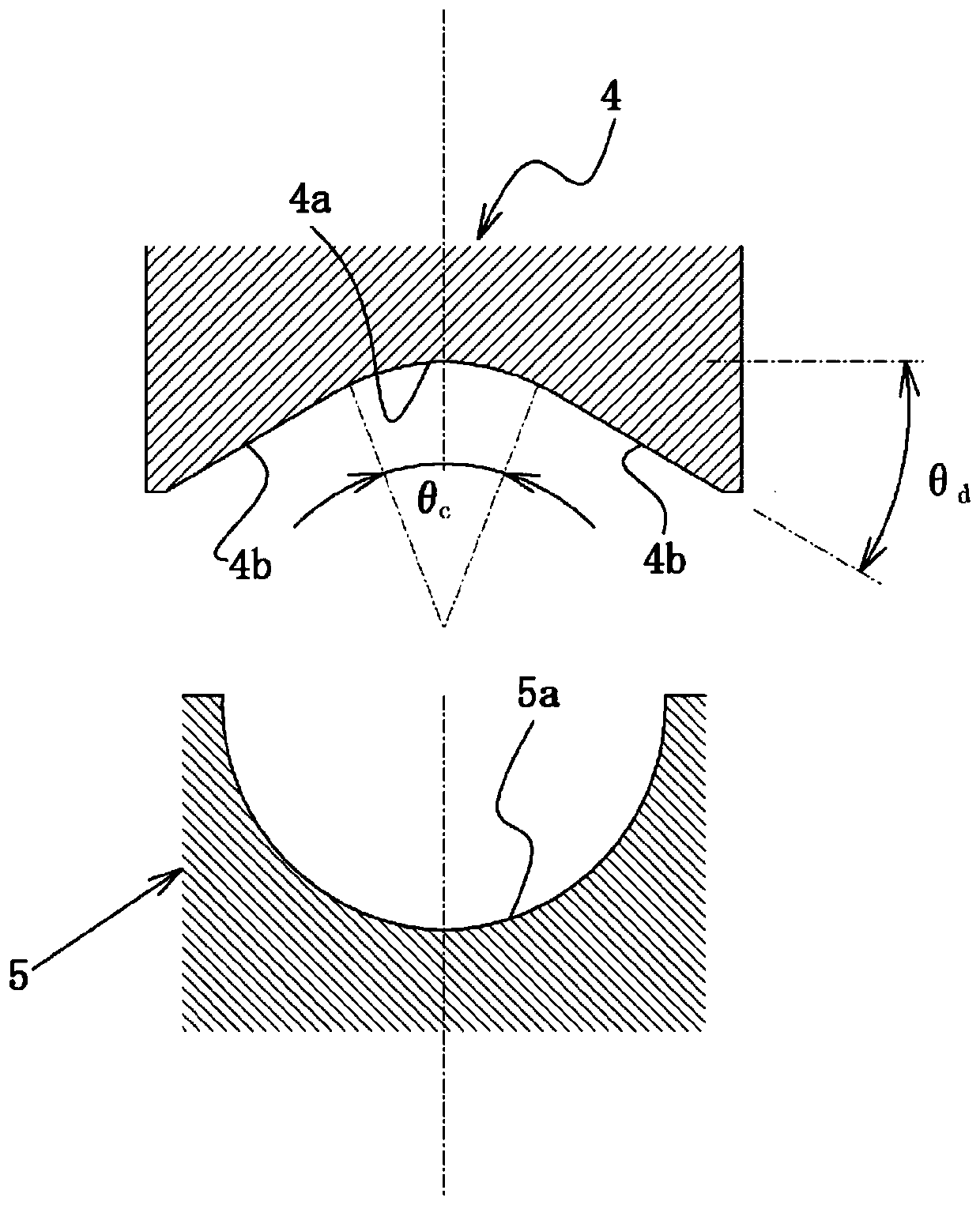

[0119] In order to form a steel pipe with a diameter of 42 inches from a line pipe steel plate (API grade X80) with a thickness of 44.5mm, a width of 3180mm, and a length of 12.2m, it is placed on a die with the interval between rod-shaped parts set at 500mm , Using a punch with a processed surface with a radius of 360mm, perform bending processing of 3-point bending, and prepare a molded body in a U-shaped cross-section with different positions and lengths of the unprocessed part from the width end.

[0120] Next, a lower mold having a concave arc surface with a radius R of 609.6 mm is set on the rod-shaped member, and the molded body having a U-shaped cross-section obtained by bending is pressed from the outside to the apex of the R portion of the mold. The distance between them (the apex of the R portion is the uppermost part of the arc surface in the upper mold, and the lowermost part of the arc surface in the lower mold) becomes 1027 mm, thereby forming an open pipe.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com