Method and system for fault detection in a compressed-air system

A compressed air and fault technology, applied in the field of identifying faults in compressed air systems, can solve expensive and other problems and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

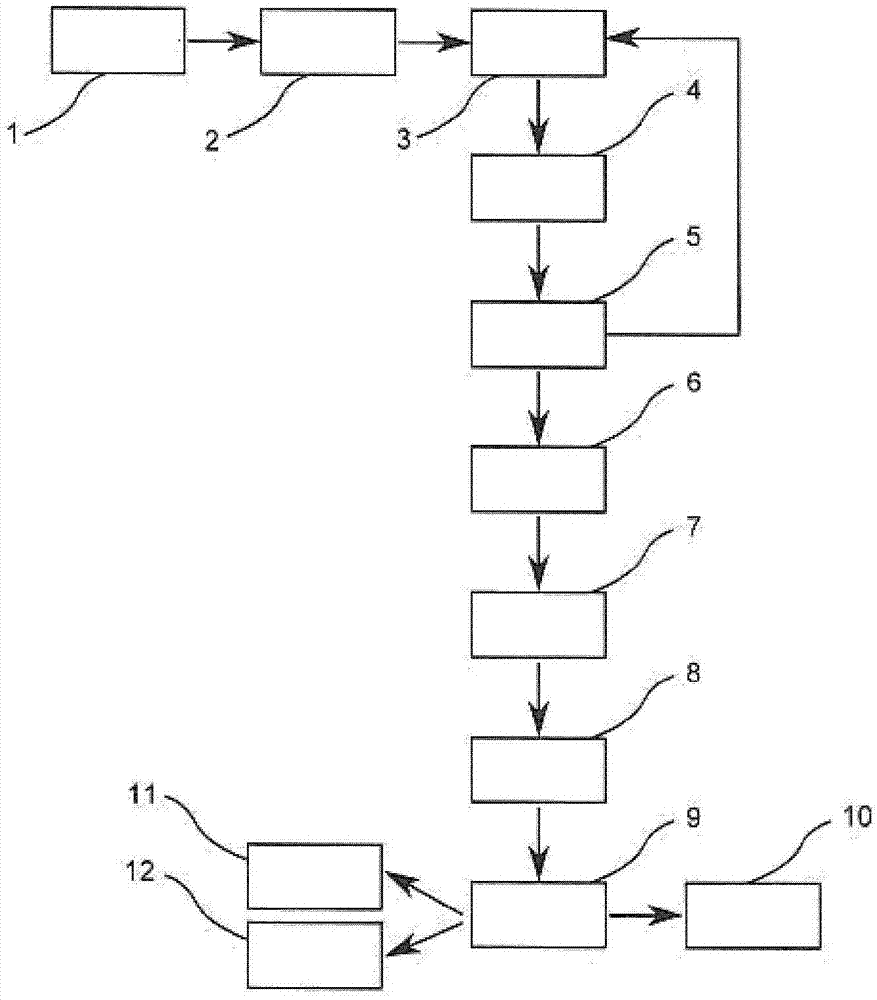

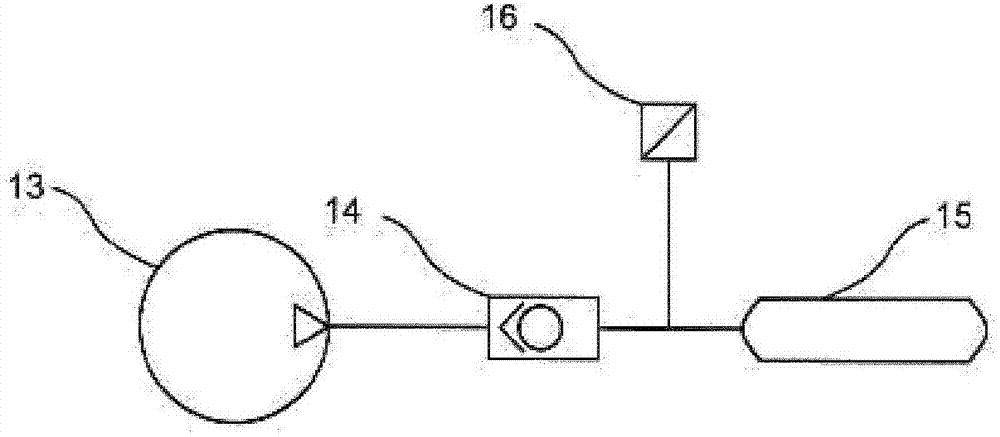

[0032] according to figure 1 , in order to detect a fault in the compressed air system, in a first step 1 the compressed air is measured on the output side of the compressor 13 and stored as a first basic value. The relevant point in time is determined by simultaneously detecting and storing the first time stamp. In the following second step 2, the compressor 13 is activated for generating compressed air. In a third step 3 which follows immediately or at intervals in time, the compressed air is measured again and stored as a comparison value. In a fourth step 4 , a value difference between the comparison value and the base value is generated and compared in a value comparison step 5 with a threshold value.

[0033] If the value difference is smaller than the critical value, the method is repeated from the third step 3 onwards. Otherwise, in a sixth step 6, the second time stamp is detected and the time interval from said first time stamp is calculated. In a time comparison...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com