Controllable shock absorber for motor vehicles

A shock absorber, vehicle technology, applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc., can solve the problems of small inflow section of hydraulic pipeline and inability to maintain pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

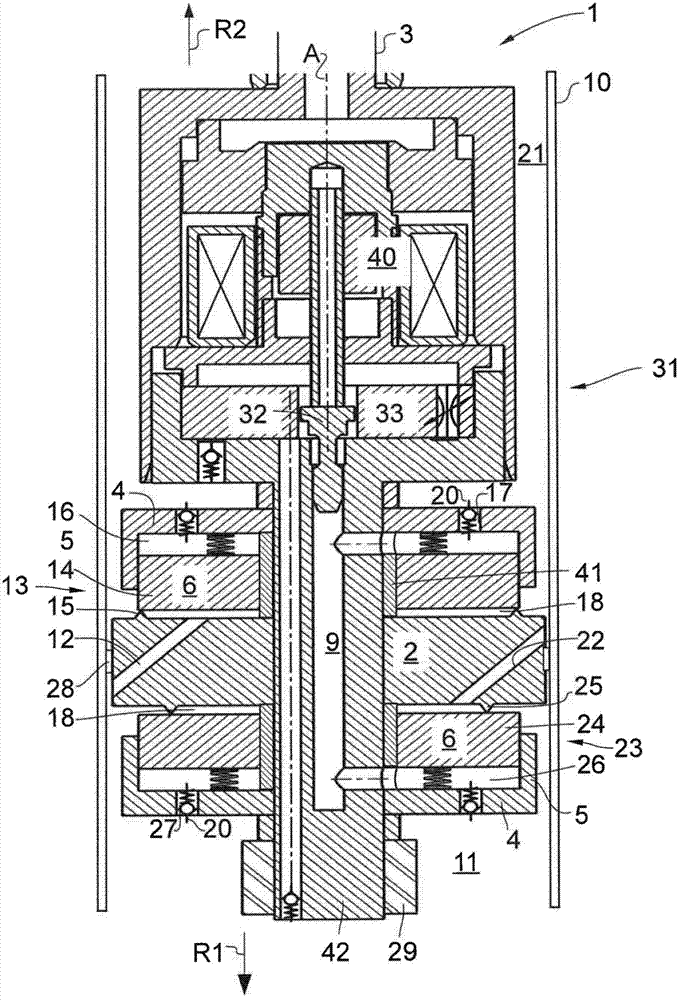

[0029] figure 1 A detail of a conventional shock absorber 1 as described in the not yet published German patent application 102013114169.2 is shown.

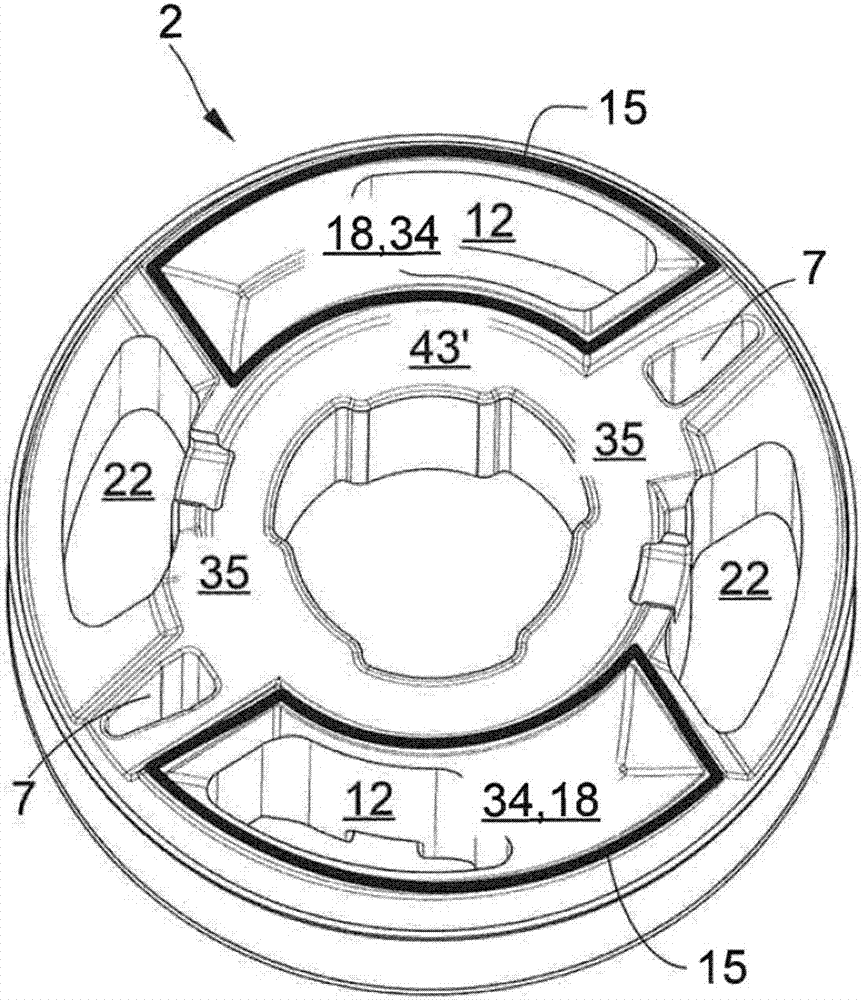

[0030] The shock absorber 1 comprises a cylinder 10 in which a piston 2 is held so as to be displaceable along a cylinder axis A. As shown in FIG. The piston 2 comprises an annular seal 28 on its outer circumference, so that the piston 2 seals the cylinder 10 into a first (piston rod facing away) working chamber 11 and a second (piston rod facing) working chamber 21 . The piston 2 is fastened to a fastening journal 42 which in turn is fixedly connected to the piston rod 3 . In case of actuation of the piston rod 3 in the first actuation direction R1 towards the first working chamber 11 (also called "compression direction"), the pressure in the first working chamber 11 increases. The fluid present in the first working chamber 11 then flows into the second working chamber 21 through the first fluid passage 12 in the piston 2 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com