Steel bar straightening and cutting device for construction machinery

A technology for construction machinery and cutting devices, which is applied in the field of steel bar straightening and cutting devices for construction machinery, can solve problems such as insufficient safety and reliability, manual intervention, and excessive pulling force, and achieve convenient and fast fixing, improve service life, and avoid excessive pulling force big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

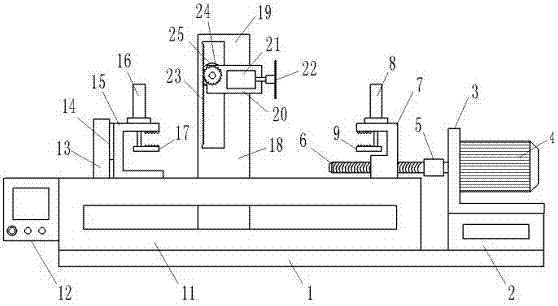

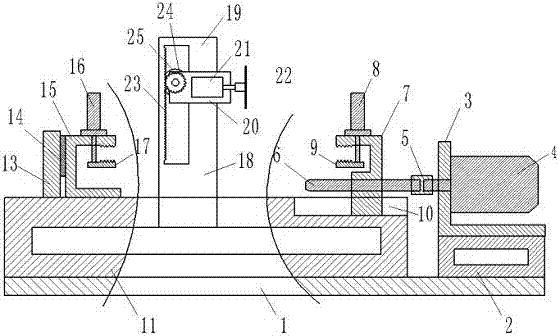

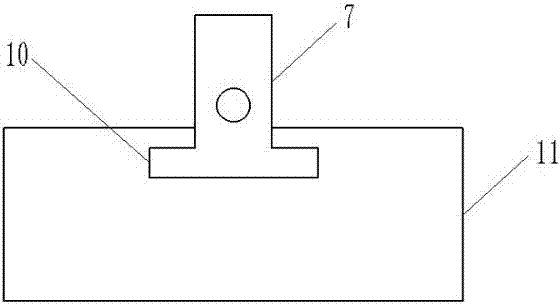

[0018] see figure 1 , in an embodiment of the present invention, a steel bar straightening and cutting device for construction machinery, comprising: a bottom plate 1, a motor mounting seat 2, an L-shaped mounting plate 3, a first motor 4, a coupling 5, a threaded rod 6, a sliding lock Tight seat 7, first hydraulic cylinder 8, first fixed plate 9, T-shaped slide rail 10, processing mounting seat 11, control module 12, fixed column 13, pressure sensor 14, U-shaped mounting plate 15, second hydraulic cylinder 16 , the second fixed plate 17, the installation column 18, the guide rail 19, the sliding mounting seat 20, the second motor 21, the cutting piece 22, the toothed guide rail 23, the gear 24 and the third motor 25, and the right side of the upper end surface of the base plate 1 is installed There is a motor mounting base 2, an L-shaped mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com