HGA (Head Gimbal Assembly) wire arranging mechanism

A cable and straight line technology, applied in the field of HGA cable arrangement, can solve the problems that all products cannot be used universally, the push block cannot effectively promote HGA, and the welding wire pass rate is low, so as to achieve a wide application range, improve the welding line pass rate, The effect of precise wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings of this specification.

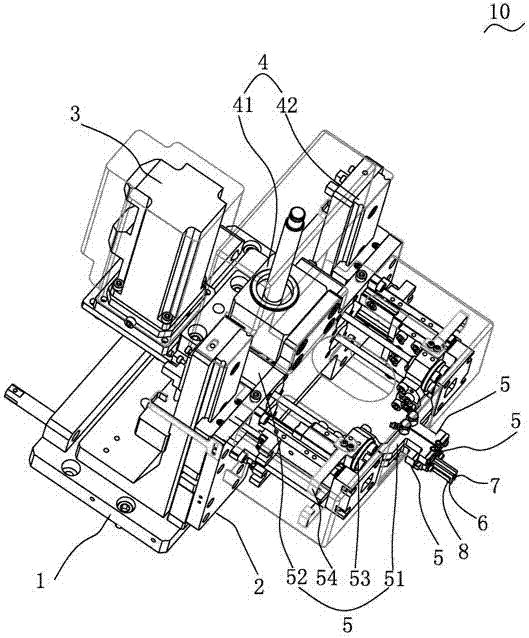

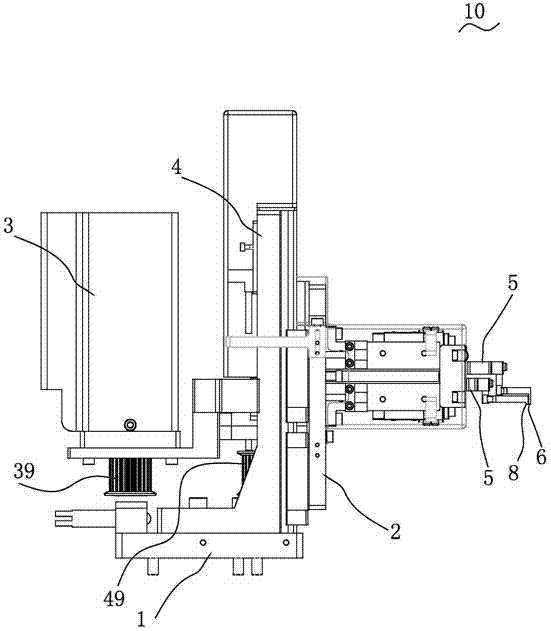

[0018] see figure 1 and figure 2 , figure 1 It is a perspective view of the HGA cable arrangement mechanism of the present invention. figure 2 It is the front view of the HGA cable arrangement mechanism of the present invention. The present invention proposes a HGA cable arrangement mechanism 10, which generally includes: a base 1; a lift base 2 mounted on the base 1 that can move up and down; a first motor 3 for driving the lift base 2 to move up and down ; be used to connect the lifting connection part 4 of this lifting base plate 2 and base 1; Four groups of horizontal drive units 5 installed on this lifting base plate 2; There are four suction head assemblies 6, 7, 8, and these four suction head assemblies 6, 7, 8 form two pairs, which can respectively carry out wiring processing on two HGAs.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com