Method for producing a transmission shaft

A transmission shaft and transmission technology, which is applied to engine components, mechanical equipment, metal processing equipment, etc., can solve the problems of transmission damage, expensive transmission shaft manufacturing, etc., and achieve reduced space requirements, reduced handling and transportation costs, and high deformation degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

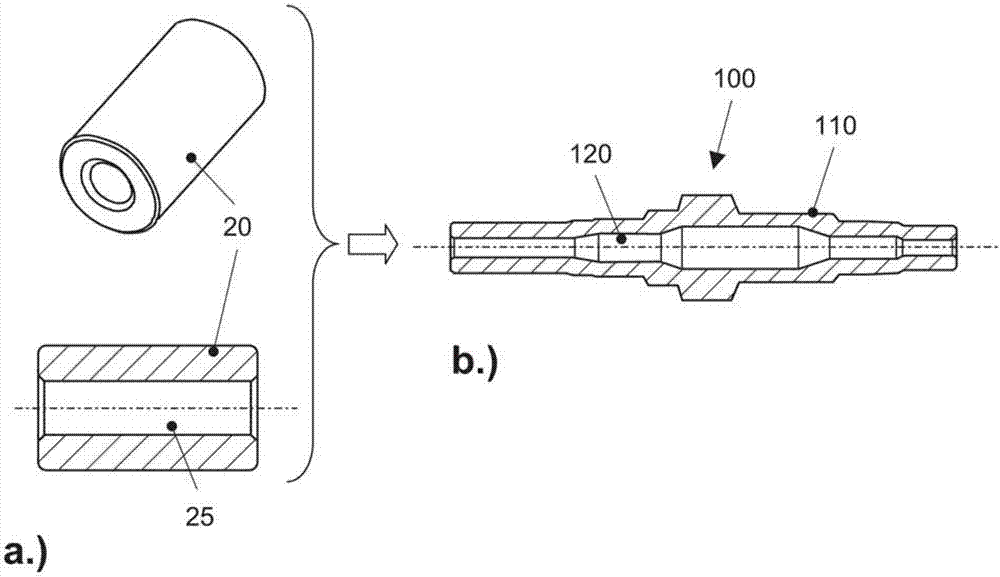

[0041] figure 1 b shows a sectional view of a shaft base body 100 for a hollow drive shaft, here the main shaft of the transmission. The shaft base body 100 has an outer contour 110 and an undercut inner contour 120 , which has a plurality of sections of different diameters. The shaft base 100 is made of the figure 1 The blank 20 shown in a is made. The cylindrical blank 20 is pre-drilled and has coaxial, cylindrical holes 25 .

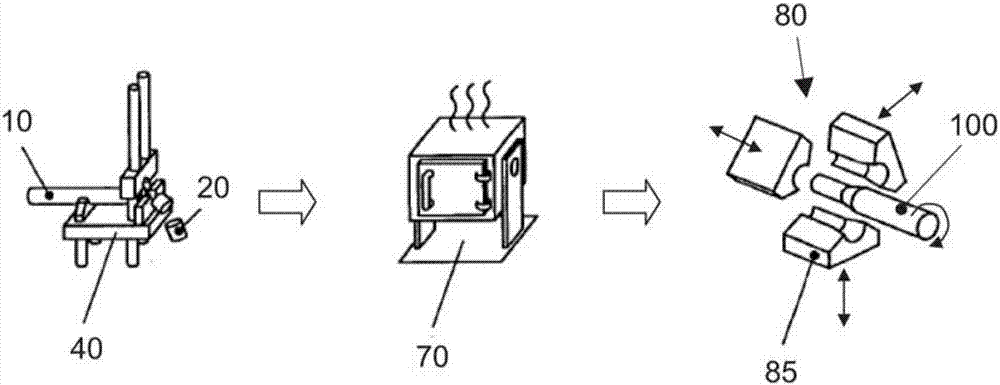

[0042] figure 2 The main steps in the manufacture of the shaft base body 100 are illustrated. In the cutting device 40 or the separating device 40 , the blank 20 is separated from the tubular semi-finished rod 10 . The tubular semi-finished rod 10 is made of steel with a ferritic-pearlitic structure. The blank 20 is heated by means of the heating device 70 to a temperature slightly below the Ac1 temperature (723°C). The heating device 70 is, for example, a furnace. This heating can also advantageously take place by means of an inductive heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com