Screw-type synchronous jacking automatic control track plate demolding machine

A technology of synchronous jacking and track plate, applied in the direction of manufacturing tools, ceramic molding machines, auxiliary molding equipment, etc., can solve difficult personnel rhythm, force synchronization, inconsistent screw extension height, cracks at the lifting point of the rail platform, etc. problems, to achieve good promotion and application prospects, ensure quality, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

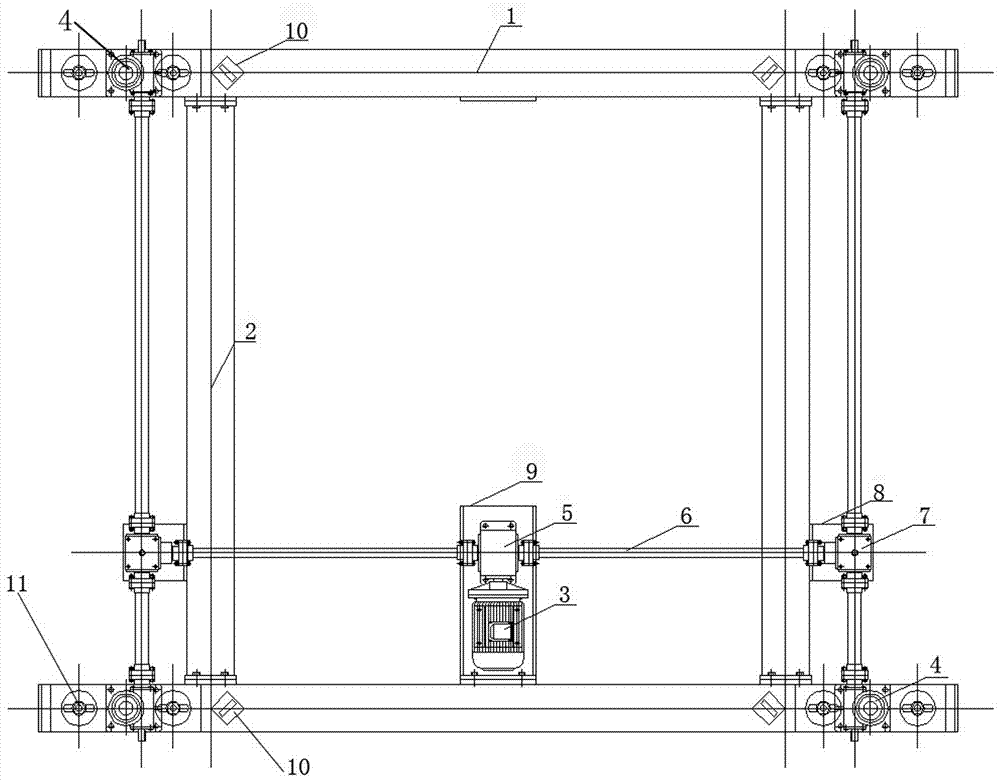

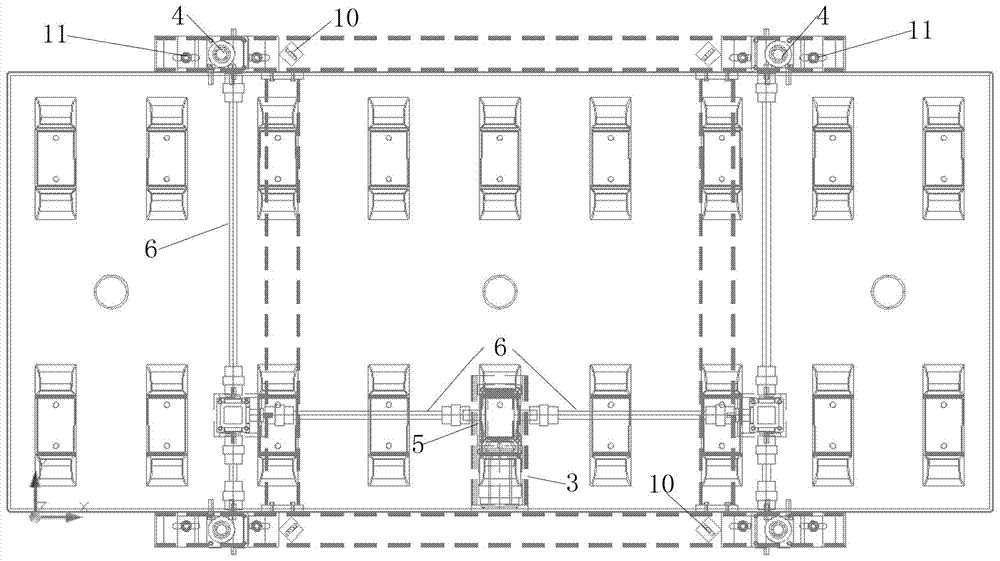

[0029] Basic working principle of the present invention:

[0030] 1. Utilize the structural form of the motor acceleration and deceleration machine to convert the electric energy as the power source into the rotational mechanical energy required by the equipment to provide sufficient power for the separation of the track plate and the mold.

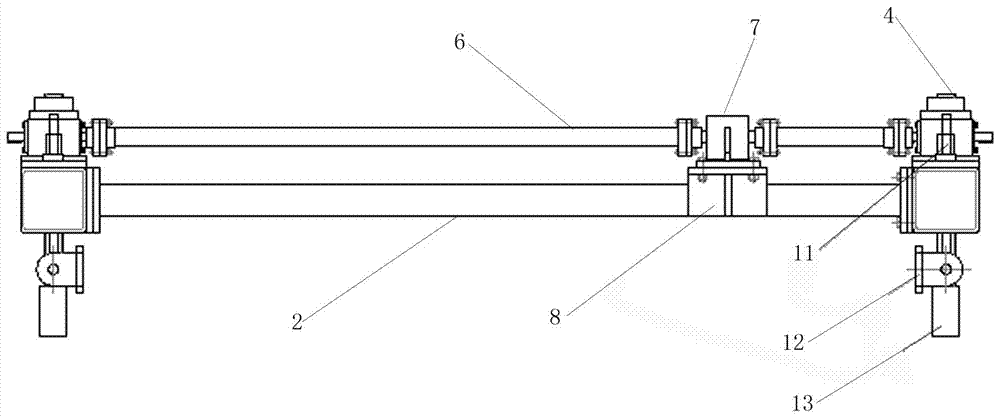

[0031] 2. Utilize the structural form of the mechanical connection between the transmission shaft and the commutator to simultaneously transmit the unique rotational force to four mechanical jacks, and realize synchronous jacking control through the synchronous rotation of the machinery.

[0032] 3. Using four threaded mechanical jacks as the power output mechanism, the synchronous precision is achieved through the threads, and the jacking process is realized while the screw rotates.

[0033] 4. Install and fix the lifting hanging plate on the lifting sleeve of the track plate, and cooperate with the U-shaped lifting block on the strippin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com