Pulping and stirring system of grouting machine in civil engineering

A civil engineering and mixing system technology, which is applied in clay preparation devices, cement mixing devices, chemical instruments and methods, etc., can solve the problems of difficult slurry mixing, difficulty in meeting the requirements of high-precision mixing, and low mixing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A specific embodiment of the present invention will be described in detail below with reference to the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

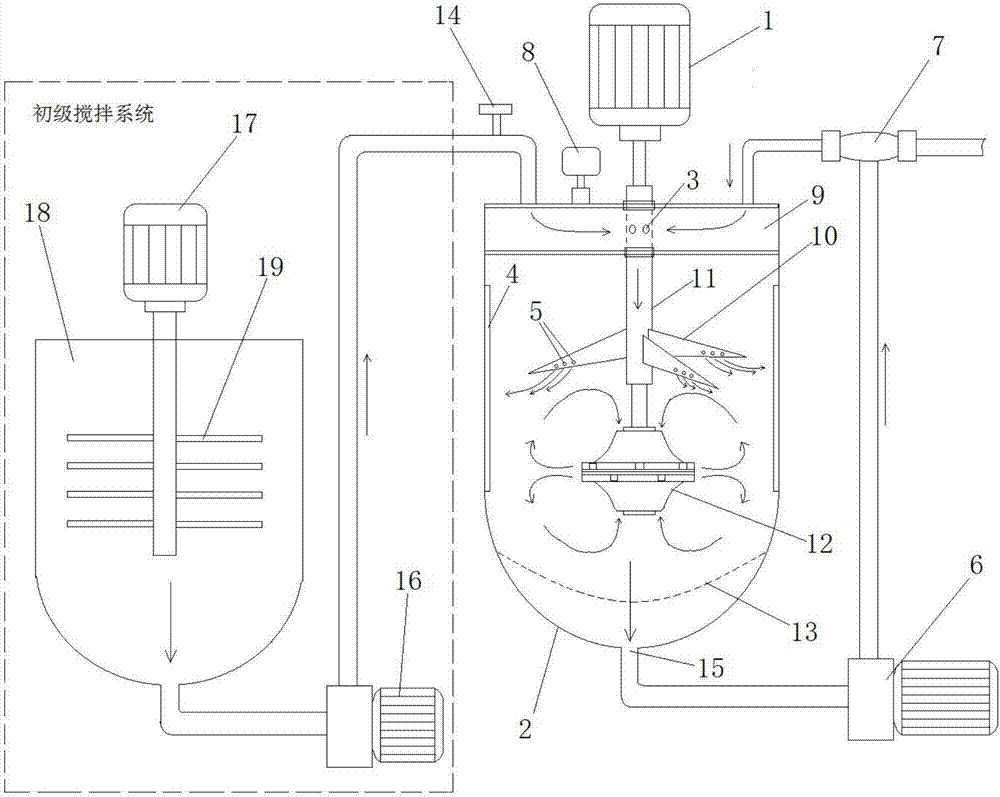

[0017] See figure 1 , The embodiment of the present invention provides a slurry mixing system for a slurry press in civil engineering, including a slurry barrel 2, a first agitator, and a first stirring motor 1. The upper end of the slurry barrel 2 is provided with a Slurry input port, the first stirring motor 1 is arranged above the pulping barrel 2 and connected to the first agitator shaft provided in the pulping barrel 2, and the upper end of the pulping barrel 2 is provided with a slurry buffer cavity 9 The first agitator includes a stirring shaft 11 that passes through the slurry buffer cavity 9 and slides and seals with the upper and lower walls of the slurry buffer cavity 9, and the lower end of the stirring shaft 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com