Cooling system for mass concrete

A large-volume concrete cooling and cooling technology, which is applied in the cooling and cooling system of large-volume concrete and the field of cooling and cooling systems, can solve the problems of unreasonable layout of cold water pipes, untimely treatment of circulating water, discounted cooling effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

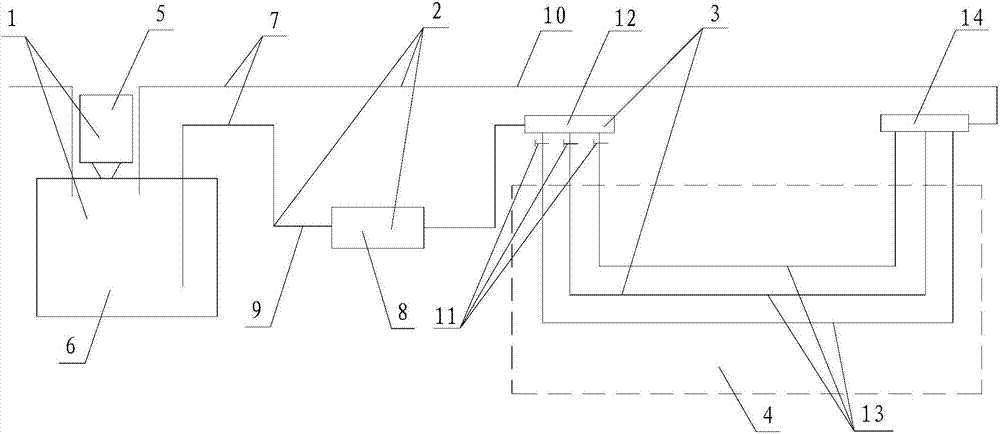

[0026] Implementation of the present invention comprises the following steps:

[0027] 1. Site layout: The circulating pool 2 is built according to the construction site, and the size and depth of the circulating pool 2 are determined according to the site size and water consumption.

[0028]2. Embedding of cooling water pipes: Calculate the amount of cooling water pipes 8 for each plane layer according to the volume of concrete pouring, and embed the cooling water pipes 8 in the concrete foundation 9 according to the design requirements.

[0029] 3. Install the control valve: install the control valve 7 at the water inlet port of each cooling water pipe 8, and check whether it is in normal use.

[0030] 4. Installation of the conversion iron pipe: After the installation of the control valve 7 is completed, a hole is reserved on the conversion iron pipe 6 according to the diameter of the cooling water pipe 8 and the number of interfaces, and the cooling water pipe 8 is welded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com