A kind of preparation method of 4-bromodiphenyl ether

A technology of brominated diphenyl ether and diphenyl ether, which is applied in the field of preparation of 4-bromodiphenyl ether, can solve the problems of unsatisfactory yield and quality, too many post-processing steps, cumbersome operation, etc., and achieve low raw material cost, The effect of low cost and simple equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

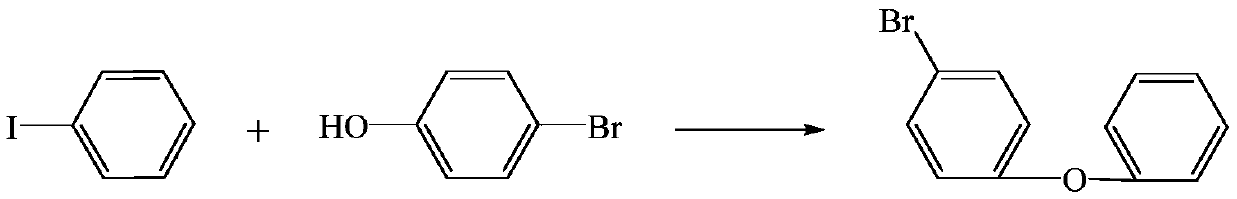

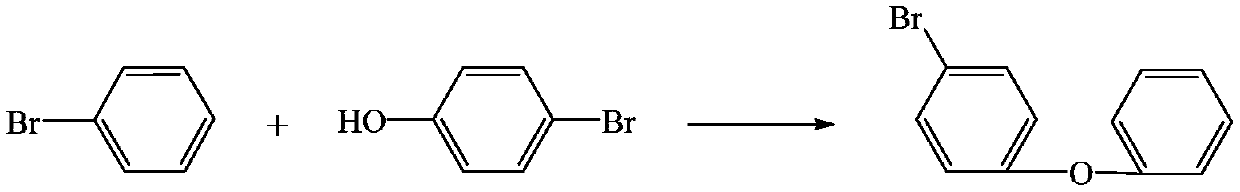

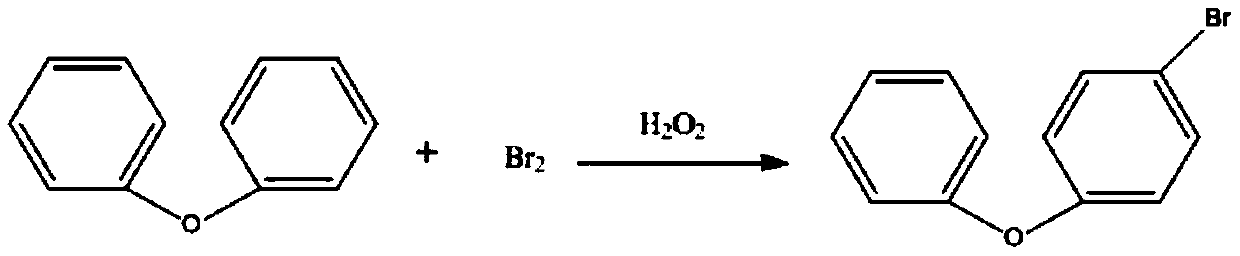

Method used

Image

Examples

Embodiment 1

[0031] Put diphenyl ether (44.2g, 0.26mol) into a 250ml four-necked bottle, add (123.5g, (1.25mol) dichloroethane and stir for 1 hour, cool down to -5~0°C, and quickly drop (21g, 0.13mol) ) bromine, stirred for 1 hour, cooled down to -5~0°C, started to drop 30% hydrogen peroxide (15g, (0.13mol), and finished dropping in 0.5~1 hour, the temperature was controlled between 0~5°C, After the dropwise addition, the temperature was naturally raised to 25°C, kept at 27°C for 32 hours, quenched with 49g of 15% sodium bisulfite, after phase separation, washed with water to neutrality, and distilled to recover dichloroethane. Diphenyl ether was recovered by distillation under reduced pressure, and 51.7 g of 4-bromodiphenyl ether was finally collected, with a yield of 80.0% and a content of 98.2%.

Embodiment 2

[0033] Put diphenyl ether (44.2g, 0.26mol) into a 250ml four-necked bottle, add (109g, 1.1mol) dichloroethane and stir for 1 hour, cool down to -5 ~ 0°C, and quickly drop (25.6g, 0.16mol) Bromine, stir for 1 hour, cool down to -5~0°C, start to add 30% hydrogen peroxide (15g, 0.13mol) dropwise, and finish the dropwise addition in 0.5 hour, control the temperature between 0~5°C, after the dropwise addition Naturally heat up to 25°C, keep warm at 28°C for 30 hours, quench with 49g of 15% sodium bisulfite, separate phases, then wash with water to neutrality, de-distill and recover dichloroethane, and recover by vacuum distillation Before boiling diphenyl ether, 47.8 g of 4-bromodiphenyl ether was finally collected, with a yield of 74.0% and a content of 98.5%.

Embodiment 3

[0035] Put diphenyl ether (44.2g, 0.26mol) into a 250ml four-necked bottle, add (136g, 1.37mol) dichloroethane and stir for 1 hour, cool down to -5~0°C, and quickly drop in (17.3g, 0.11mol) Bromine, stir for 1 hour, cool down to -5~0°C, start to add 30% hydrogen peroxide (15g, 0.13mol) dropwise, and finish the dropwise addition in 0.6 hours, control the temperature between 0~5°C, after the dropwise addition Naturally raise the temperature to 25°C, keep warm at 25°C for 48 hours, quench with 49g of 15% sodium bisulfite, separate phases, then wash with water until neutral, distill and recover dichloroethane, and recover by vacuum distillation Before boiling diphenyl ether, 49.3 g of 4-bromodiphenyl ether was finally collected, with a yield of 76.3% and a content of 98.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com