Carbon dioxide heat pump heat supply system

A heating system, carbon dioxide technology, applied in heating systems, hot water central heating systems, household heating, etc., to achieve the effect of improving heat exchange efficiency, high energy efficiency, and low heating heat attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

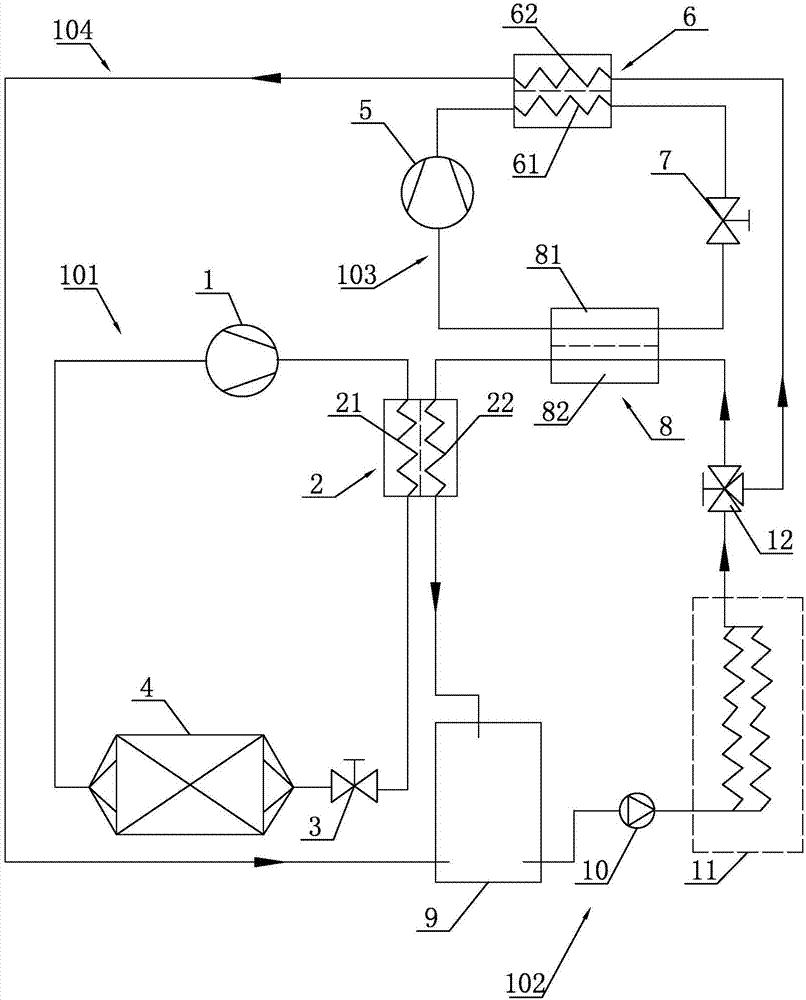

[0027] Such as figure 1 As shown, a carbon dioxide heat pump heating system according to the present invention includes a control unit (not shown). The control unit can control the heating system to supply heat to the heating area. The heating system also includes a first circulation loop 101 , a heating circulation loop 102 , a second circulation loop 103 and a distribution pipeline 104 . A gas cooler ( 2 ) is arranged between the first circulation loop 101 and the heating circulation loop 102 . The gas cooler 2 has a first heat exchange pipeline 21 and a second heat exchange pipeline 22 arranged adjacently. A second evaporator 8 is arranged between the heating circulation loop 101 and the second circulation loop 102 . The second evaporator 8 has a third heat exchange pipeline 81 and a fourth heat exchange pipeline 82 arranged adjacently. A condenser 6 is provided between the second circulation loop 103 and the split pipeline 104 . The condenser 6 has a fifth heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com