Carbon dioxide heat pump system and control method thereof

A technology for carbon dioxide and heat pump systems, applied in heat pumps, refrigerators, refrigeration components, etc., can solve problems such as damage to carbon dioxide heat pump systems, and achieve the effects of extending effective heating time, reducing exhaust temperature, and improving evaporation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

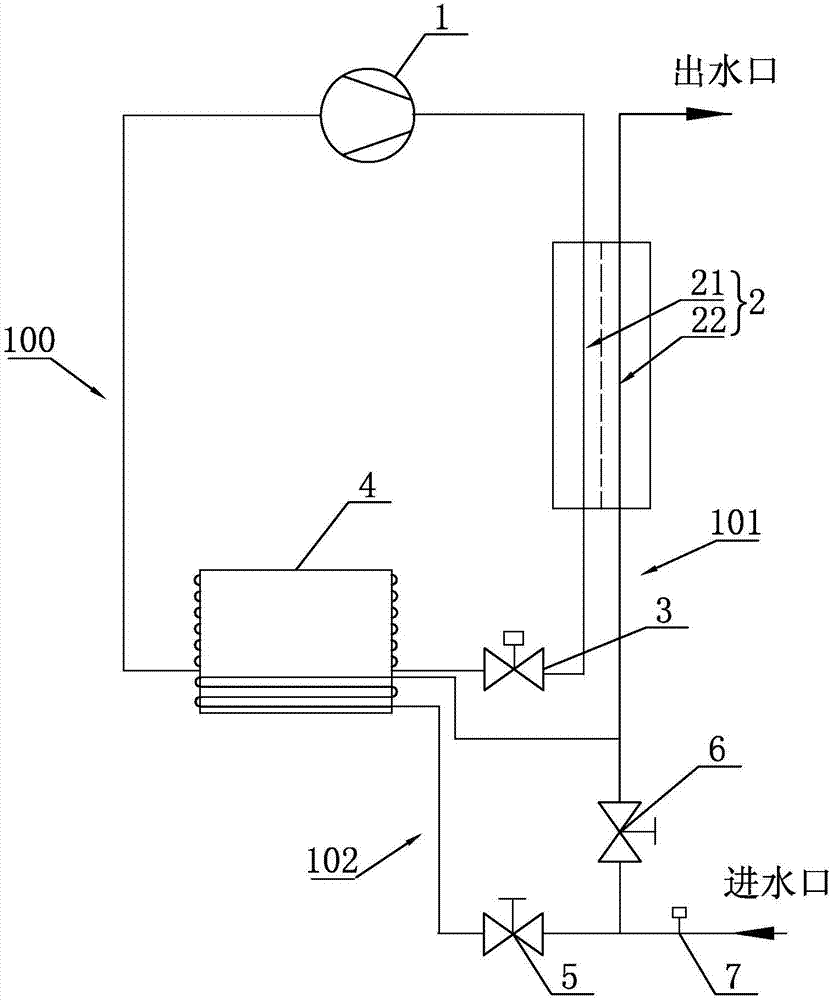

[0030] Such as figure 1 As shown, a carbon dioxide heat pump system according to the present invention includes a control unit (not shown in the figure), a carbon dioxide circulation loop 100 , a hot water supply circuit 101 and a pre-cooling water circuit 102 . The control unit can control the carbon dioxide heat pump system to supply heat or hot water to the outside. The control unit described in this embodiment is an existing common controller, such as PLC, and the control unit is not the technical point of this application, so it will not be described in detail here, and the existing structure that can realize the control function shall prevail.

[0031] The carbon dioxide circulation loop 100 is used for circulation of carbon dioxide. Both the hot water supply circuit 101 and the pre-cooling water circuit 102 are used for water supply and circulation. The carbon dioxide circulation loop 100 is provided with a carbon dioxide compressor 1 , a gas cooler 2 , a throttling m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com