Mechanical power flow closed intersecting shaft bevel gear drive test bench

A technology of bevel gear transmission and mechanical power, applied in the testing of machine gear/transmission mechanism, testing of mechanical components, testing of machine/structural components, etc. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

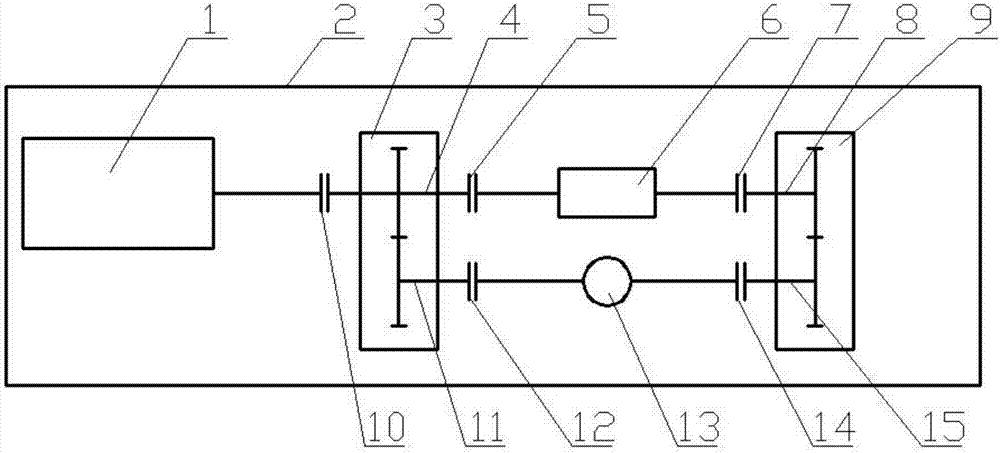

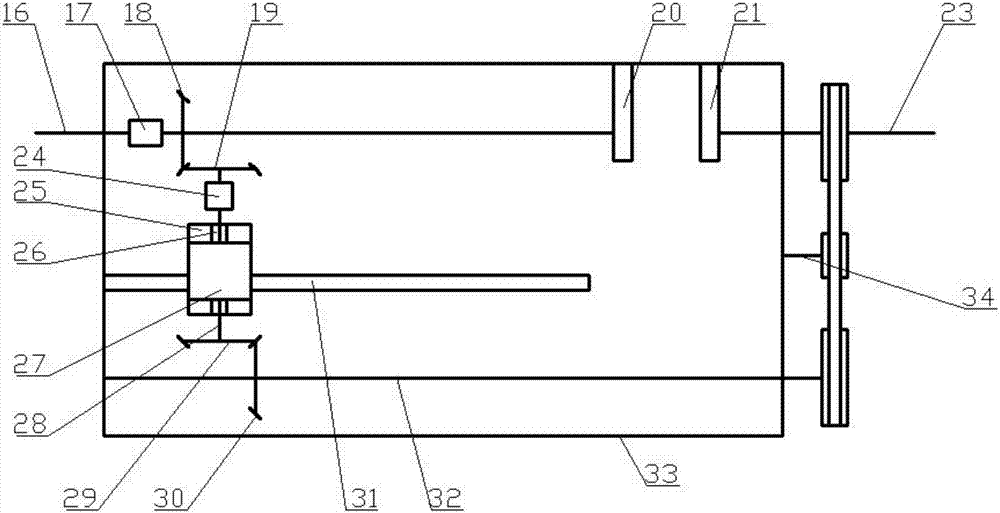

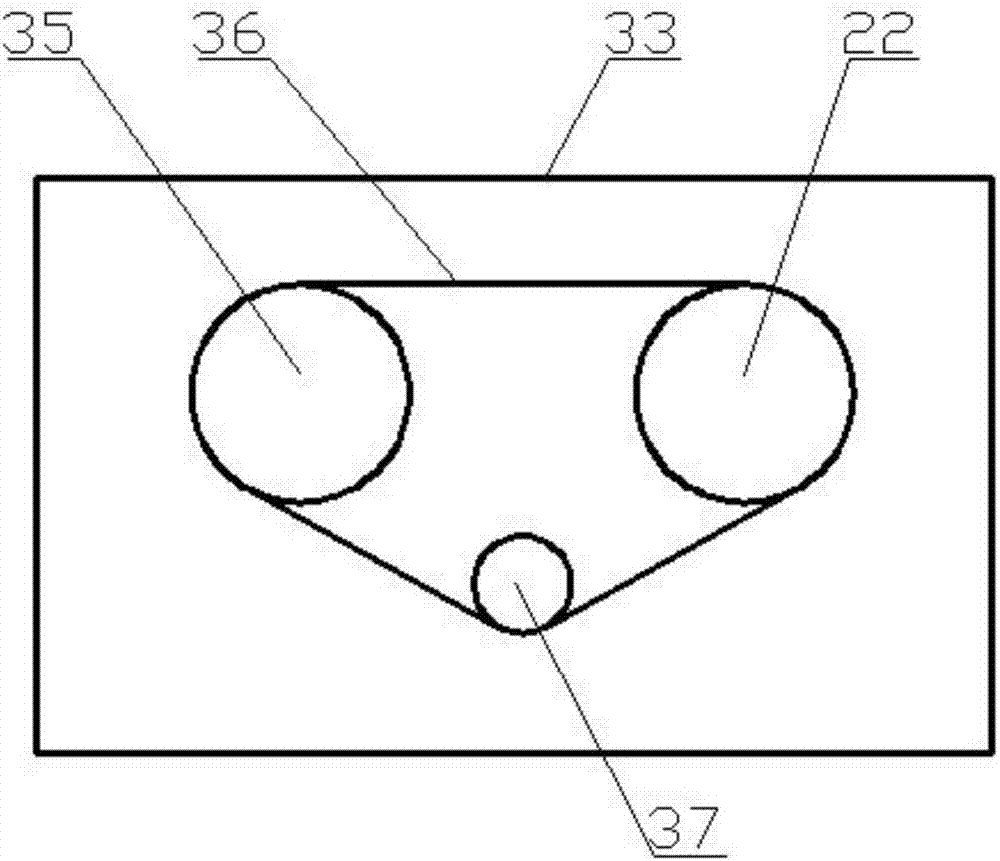

[0025] like figure 1 , 2, 3, and 4 show the mechanical power flow closed type intersecting shaft bevel gear transmission test bench, including electromagnetic speed regulating motor 1, reducer Ⅰ3, reducer Ⅱ9, shafting 4, 9, 11, 15, loading device 6, joint Shaft assembly 5, 7, 10, 12, 14, experimental bevel gear module 13, base 2; the reducer I3, reducer II 9, the loading device 6 and the experimental bevel gear module 13 pass through the shafting 4, 9, 11, 15 are connected to the coupling group 5, 7, 10, 12, 14, and the reducer I3 and reducer II9 are fixed on the base 2; the couplings 5, 7 , 10, 12, and 14 groups include coupling I5, coupling II7, coupling III10, coupling IV12, and coupling V14, and the shafting 4, 9, 11, and 15 include shaft I4 and shaft II9 , shaft III11, shaft IV15, the output shaft of the electromagnetic speed-regulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com