Three-dimensional mechanical arm production system of car body stamping sheet metal parts

A technology of automobile body and production system, which is applied in the field of forming and manufacturing automobile body stamping sheet metal parts. It can solve the problems of low safety and efficiency, low production efficiency, and troublesome disassembly of manipulator and arm fixing seat, so as to improve the efficiency of punching machine, The effect of saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

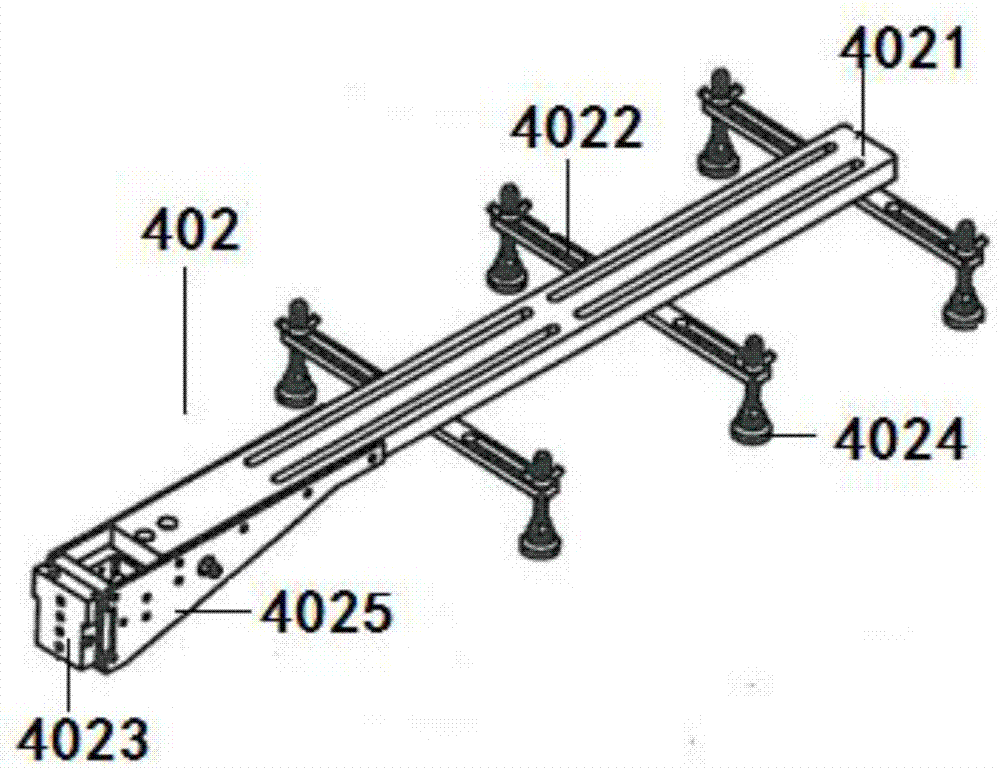

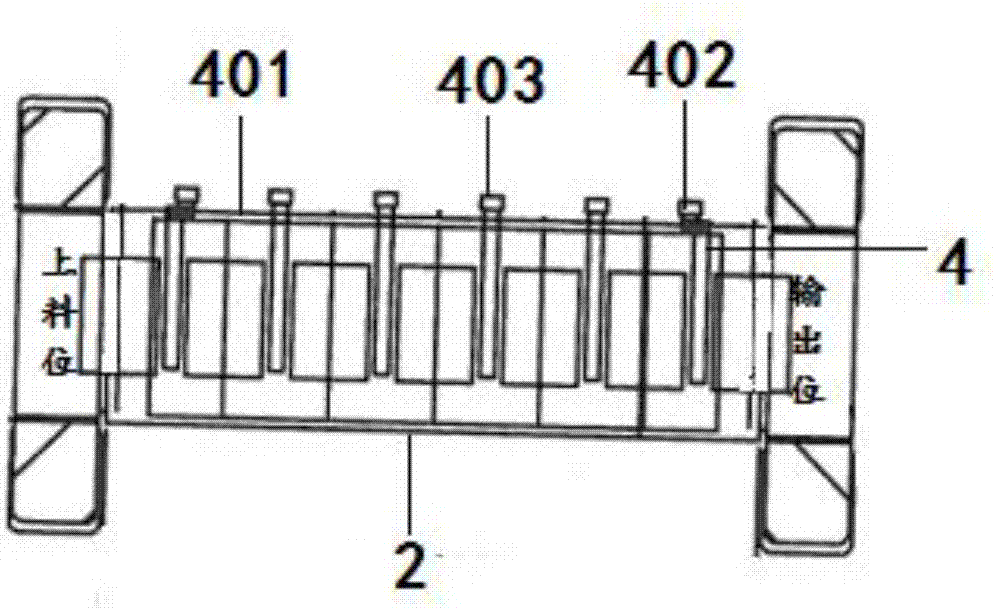

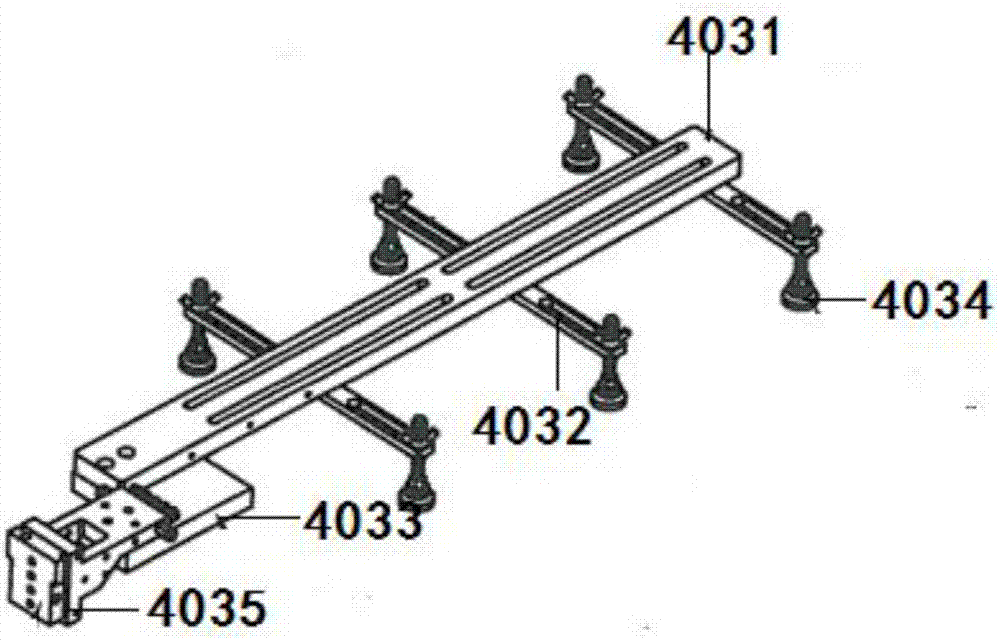

[0028] A three-dimensional manipulator production system for automobile body stamping sheet metal parts, such as figure 1 and 2 As shown, it includes a feeding structure 1, a punching machine tool 2, and an output mechanism 5. The feeding structure 1 is connected to the punching machine tool 2, and the punching machine tool 2 is connected to the output mechanism 5;

[0029] Such as image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the feeding structure 1 includes an accumulation rack 101 and a track support frame 102, the accumulation rack 101 includes a support frame 1011 and a delivery frame 1012 fixed on the top of the support frame 1011, and the support frame 1011 is fixed on the frame body Push material cylinder 1013 is arranged, and described material push cylinder 1013 is connected with push material frame 1014, and push material cylinder 1013 provides power for push material frame 1044, and the surface of described delivery frame 1012 is fixed with suction pla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap